Filtering layer of online transformer oil chromatography monitoring system

A monitoring system and transformer oil technology, applied in the direction of dispersed particle filtration, instruments, measuring devices, etc., can solve the problems of heavy workload, cumbersome operation, impurity filtration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

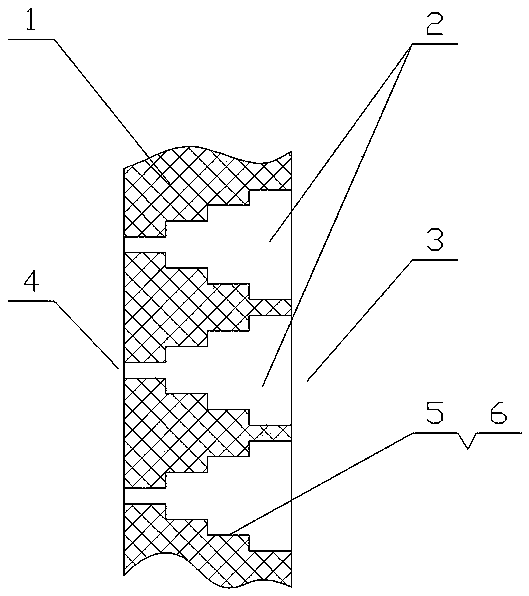

[0008] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: a filter layer for transformer oil chromatographic on-line monitoring system, this filter layer includes a substrate 1 as a base, on which a plurality of sieve holes 2 are uniformly distributed, and the cross-sections of these sieve holes 2 are horn-shaped shape, and the direction of the horn opening is the same, the two ends of the sieve hole 2 are the large hole 3 and the small hole 4, the value range of the large hole 3 is 0.8-1.2 microns, and the value range of the small hole 4 is 0.1- At the same time, the sides 5 of all trumpet-shaped sieve holes 2 are arranged in steps, and each side 5 is divided into at least three layers of steps 6, and the dimensions of each step 6 are exactly the same.

[0009] The working process of the filter layer in the embodiment of the present invention is as follows: the filter layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com