Method and device for automatically adjusting laying tension of steel wire

An automatic adjustment and pay-off tension technology, which is applied in the field of metal product processing equipment, can solve problems such as steel wire slack, messy wires, and potential safety hazards, and achieve the effects of increasing production efficiency, improving product quality, and realizing automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

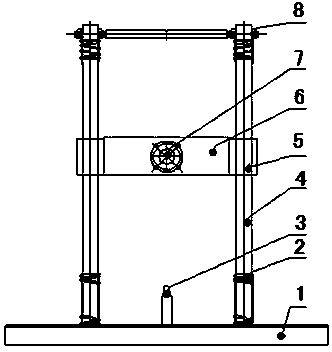

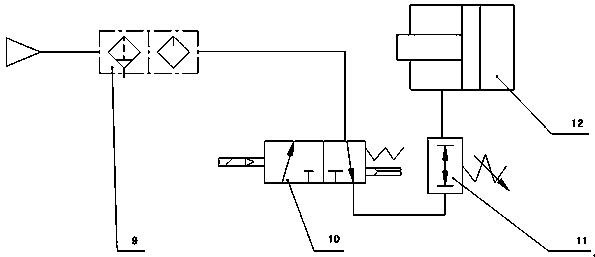

[0010] The pay-off tension automatic adjustment device of the present invention, the specific implementation is as follows figure 1 with 2 .

[0011] It consists of a constant tension adjusting device and a pneumatic part. The constant tension adjusting device consists of a bracket 1, a spring 2, a tension detection device 3, a linear guide 4, a linear bearing 5, a tension adjuster 6, a positioning wear sleeve 7 and The tie rod 8 is constituted; the linear guide rod 4 is connected and fixed on the bracket with a nut 1, the spring 2 is placed at the lower end of the linear guide rod 4, the tension adjuster 6 can slide up and down on the linear guide rod 4 through the linear bearing 5, and the wear-resistant sleeve 7 is positioned On the tension regulator 6, the tension detection device 3 is fixed on the bracket 1 with a lock nut, and the upper end of the linear guide rod 4 is connected with a tie rod 8; the pneumatic part is processed by the air source in turn, the double body 9, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com