Transmission rear housing die and casting method of transmission rear housing

A transmission and mold technology, which is applied to the transmission rear shell mold and its casting field, can solve the problems of low output efficiency and low casting quality, and achieve the effect of high output efficiency and good casting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

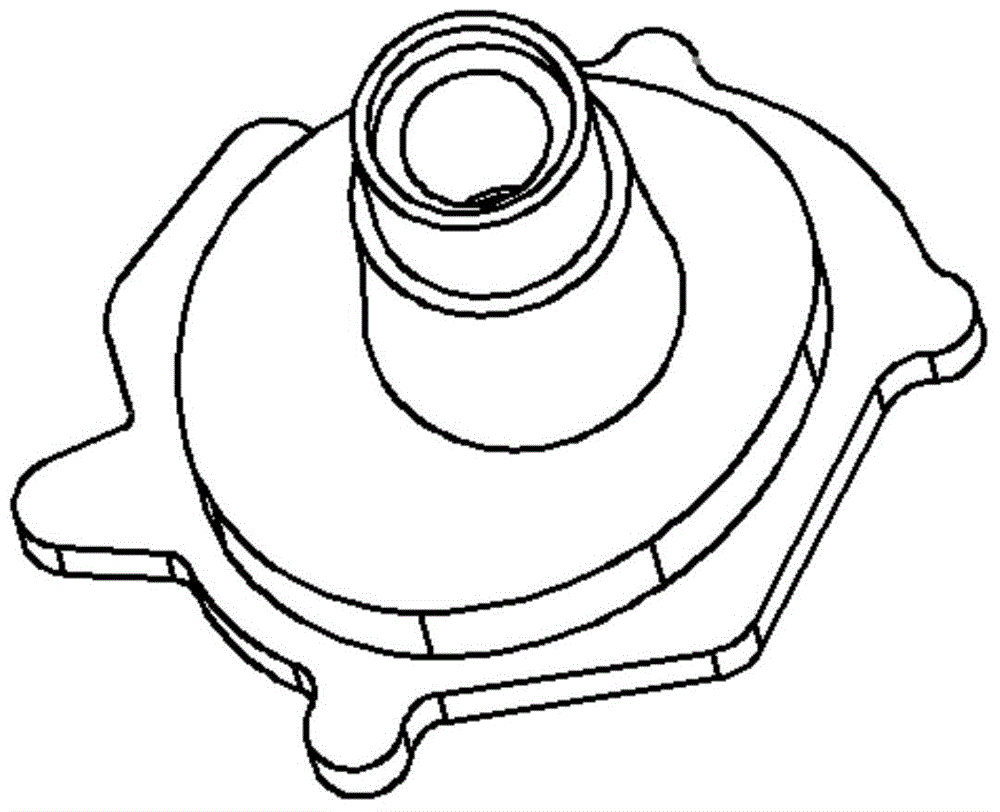

[0016] refer to figure 1 and figure 2 , a transmission back shell mold, comprising an upper mold 6, a lower mold 9, an upper mold 3 and a lower mold 10, the cavity between the upper mold 6 and the lower mold 7 is a mold cavity, and the upper mold and the upper mold The formwork is connected by bolts 4, and the lower mold and the lower formwork are also connected by bolts;

[0017] The upper template 3 is slidably set on the guide column 2 up and down, and the upper template 3 is connected with an upper driving mechanism for driving the upper template 3 to move up and down; the upper mold and the lower mold on one side of the mold cavity The junction of the molds is a runner 11, and the junction of the upper mold and the lower mold on the other side of the mold cavity is an overflow groove 7, and a first vertical guide groove and a second vertical guide groove are opened in the groove. Guide groove, the first vertical guide groove is close to the runner 11, the second vertic...

Embodiment 2

[0026] refer to figure 1 and figure 2 , a casting method of a transmission rear case, the casting method comprising the following steps:

[0027] 1) Mold closing and squeeze casting stage: the lower template 10 is fixed, the upper template 3 moves along the guide column 2 to make the upper mold 6 cooperate with the lower mold 9 to form a shell cavity for casting the rear shell of the transmission, and the push rod 8 moves to the At the position where the surface of the cavity is parallel, the extrusion head 12 squeezes upwards to squeeze the molten metal into the cavity of the mold. After filling, excess impurities such as molten metal and gas overflow from the overflow groove 7;

[0028] 2) Mold opening stage: After the extrusion casting is completed, the upper mold 3 drives the upper mold 6 to move upward along the guide column 2, and then the casting is pushed out of the cavity from the lower mold 9 through the simultaneous upward movement of the extrusion head 12 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com