Polishing pressure tester for cover plate faces in precise grinding and polishing operation of glass cover plates

A glass cover, a technology in operation, applied in grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc., can solve the problems of waste of labor cost and equipment capacity, low polishing process yield, and high product cost , to achieve the effect of fast measurement speed, easy access and comparison, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

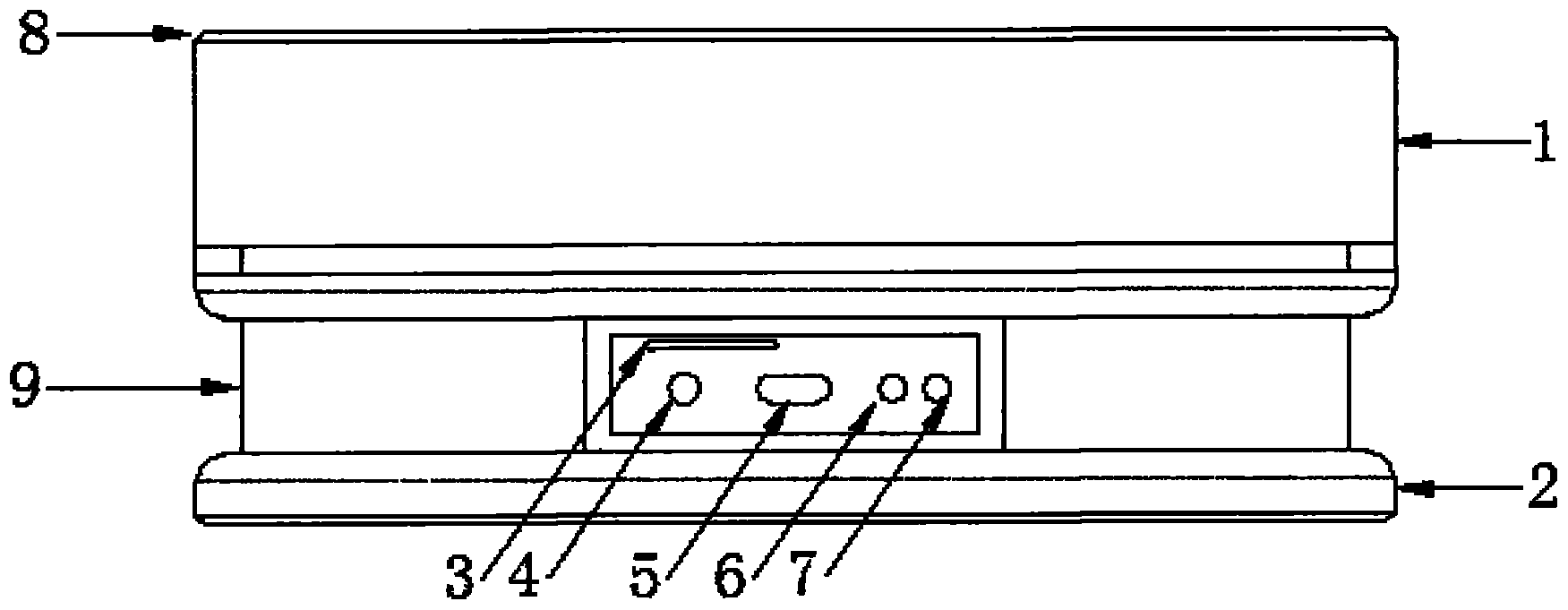

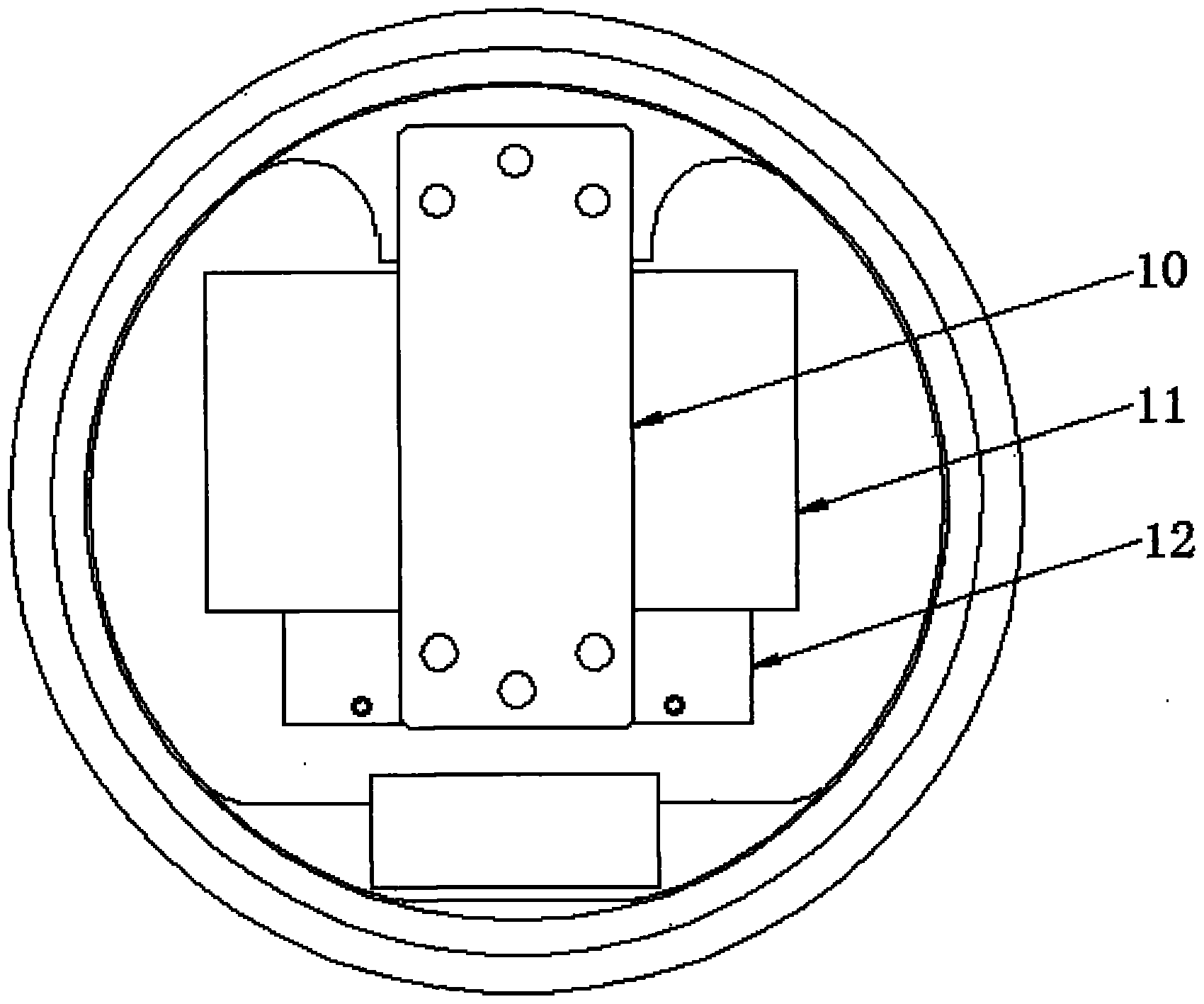

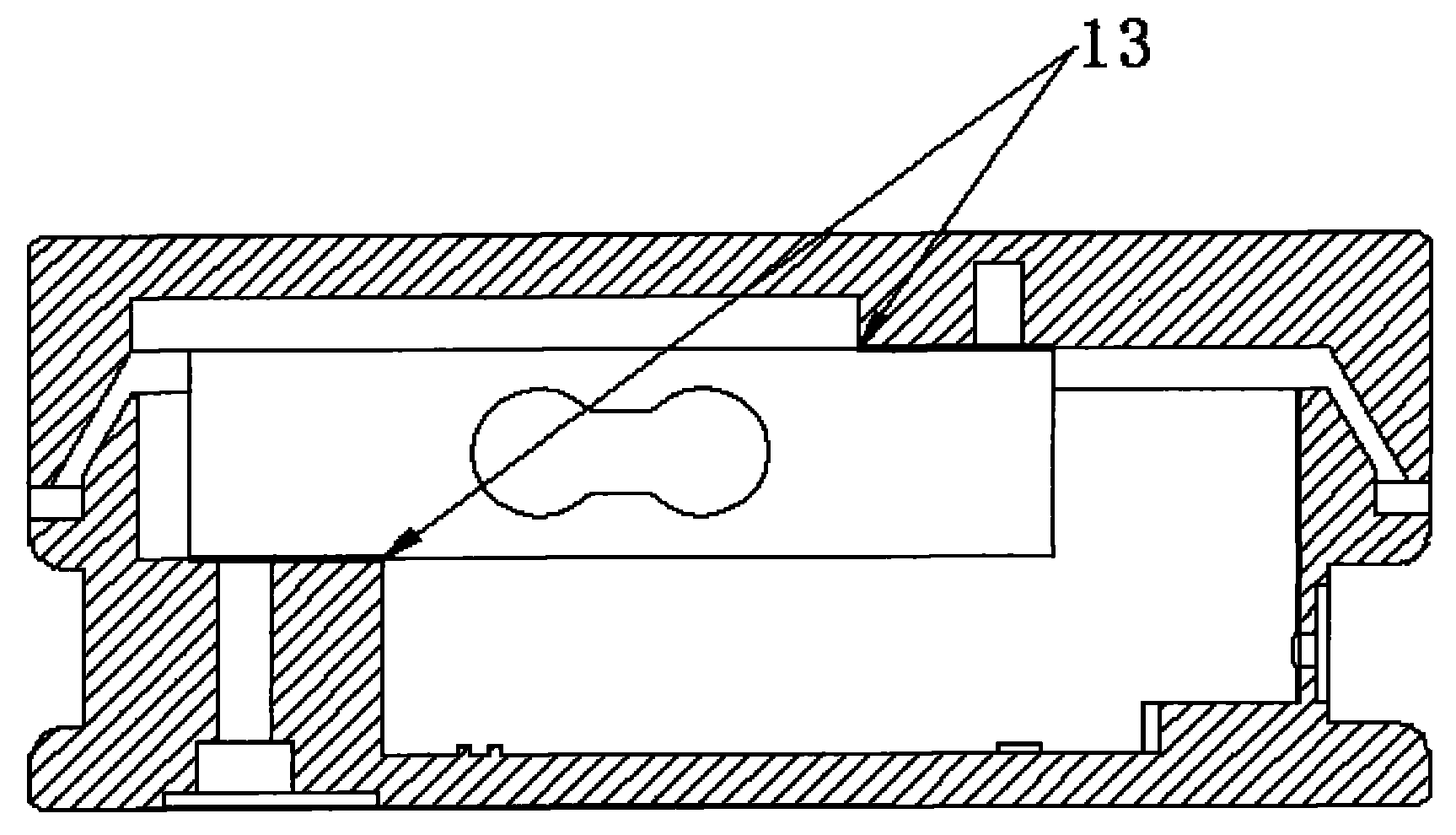

[0019] Such as Figure 1 to Figure 5 As shown, a cover surface polishing pressure tester in a glass cover precision grinding and polishing operation of the present invention includes a monitoring host and an acquisition instrument 14, wherein the monitoring host includes a base 2 with a circular cross section, an induction panel 1 and a set The electronic scale sensor 10 in the base, the electronic scale sensor 10 is a block structure whose top surface and bottom surface are parallel to each other, the top surface of one side of the electronic scale sensor is fixedly connected with the bottom surface of the induction panel, and the bottom surface of the other side is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com