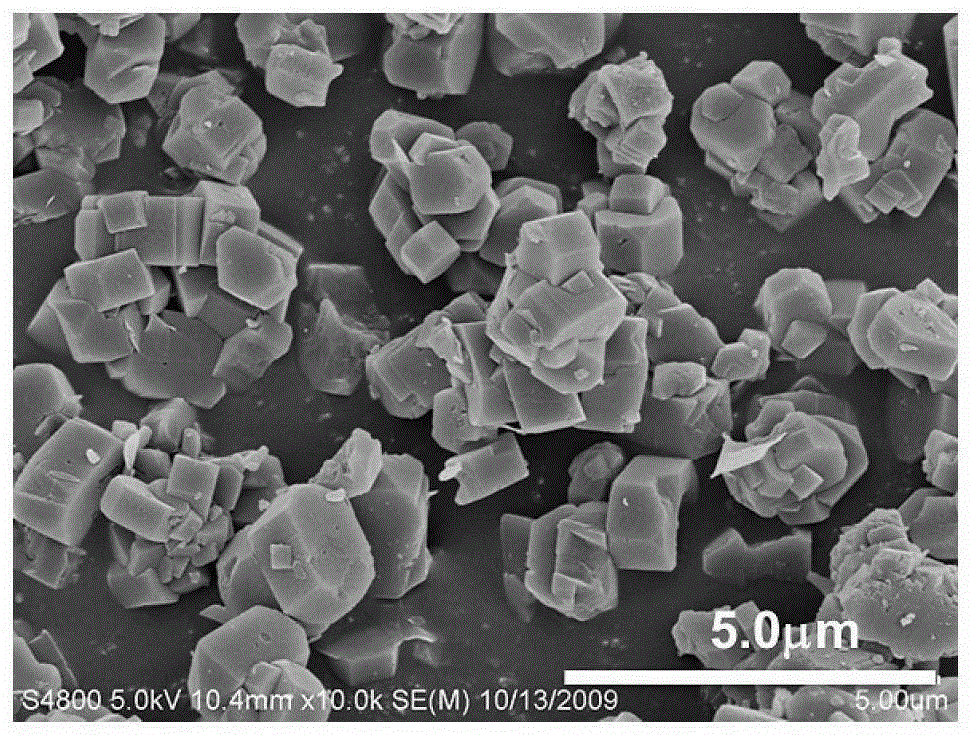

A kind of zsm-5-based hierarchical porous molecular sieve material and preparation method thereof

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of increasing the complexity of the synthesis process, unfavorable large-scale production, and increasing synthesis costs. Achieve good micro-mesopore distribution, reduce the dosage, and achieve the effect of good mesopore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

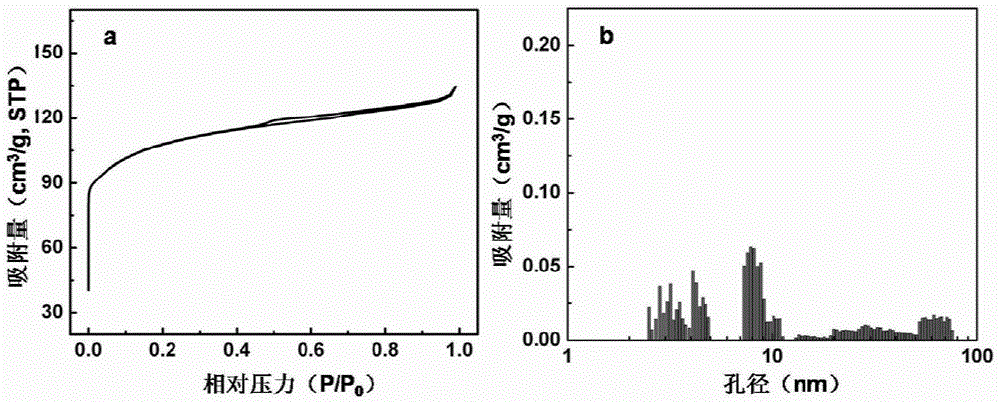

Method used

Image

Examples

Embodiment 1

[0045] Under stirring conditions, prepare the following two working solutions respectively:

[0046] Mixture I: a homogeneous solution prepared with 1.39g of aluminum sulfate, 1.57g of sodium hydroxide and 10g of deionized water;

[0047] Mixture II: 17.27g silica sol (40% SiO 2 , 60%H 2 O, hereinafter the same), 0.92g tetrapropylammonium bromide (99%), 10g deionized into the beaker and mix well.

[0048] Under constant stirring, the two mixtures are mixed, and continue to be strongly stirred until uniform, and the mass ratio of the obtained reaction mixture is Na 2 O: Al 2 o 3 : SiO 2 : (TPA) 2 O: H 2 O=9.0:1.0:55:0.82:825, transfer the obtained initial gel to a reaction kettle with a polytetrafluoroethylene liner, seal it and place it in a hydrothermal synthesis oven, and keep the temperature at 80°C for 24h. Then be warming up to 175 DEG C and continue constant temperature 24h. After the reaction kettle was cooled, the solid was separated from the mother liquor, th...

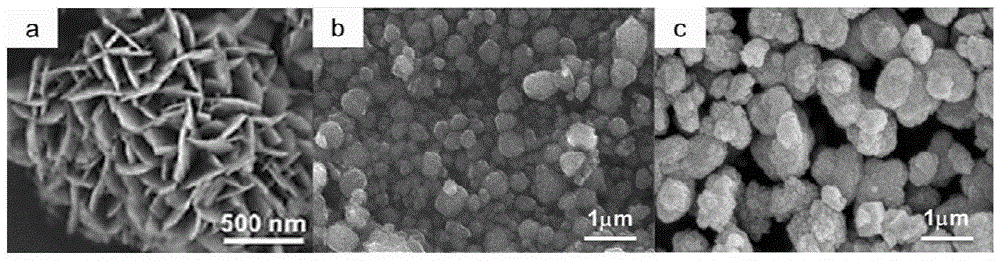

Embodiment 2

[0051] Under stirring conditions, prepare the following two working solutions respectively:

[0052] Solution I: a uniform solution prepared with 1.27g of aluminum sulfate, 1.91g of sodium hydroxide and 10g of deionized water;

[0053] Solution II: Put 8.61g of silica sol, 0.23g of tetrapropylammonium bromide, and 10g of deionized into a beaker and mix well.

[0054] With constant stirring, combine the two mixtures and continue stirring vigorously until homogeneous. The molar ratio of the initial gel is Na 2 O: Al 2 o 3 : SiO 2 : (TPA) 2 O: H 2 O=12.0:1.0:30:0.23:750. The obtained initial gel was transferred to a reaction kettle with a polytetrafluoroethylene liner, sealed and placed in a hydrothermal synthesis oven. The temperature was first kept at 80°C for 24h, and then the temperature was raised to 175°C for 30h. After the reaction kettle was cooled, the solid was separated from the mother liquor, the solid was washed with deionized water until neutral, dried at 12...

Embodiment 3

[0056] Under stirring conditions, prepare the following two working solutions respectively:

[0057] Solution I: a uniform solution prepared by 0.25g aluminum sulfate, 0.25g sodium hydroxide and 10g deionized water;

[0058] Solution II: Add 11.20g silica sol, 0.40g tetrapropylammonium bromide, and 10g deionized into a beaker and mix well.

[0059] With constant stirring, combine the two mixtures and continue stirring vigorously until homogeneous. The molar ratio of the initial gel is Na 2 O: Al 2 o 3 : SiO2 : (TPA) 2 O: H 2 O=8.2:1.0:200:2.0:4000. The obtained initial gel was transferred to a reaction kettle with a polytetrafluoroethylene liner, sealed and placed in a hydrothermal synthesis oven. The temperature was first kept at 80°C for 12h, and then the temperature was raised to 170°C for 16h. After the reaction kettle was cooled, the solid was separated from the mother liquor, the solid was washed with deionized water until neutral, dried at 120°C in air, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com