Beta/ZSM-5 compound borosilicate molecular sieve and preparation method thereof

A technology of ZSM-5 and molecular sieves, which is applied in the field of composite molecular sieves and its preparation, can solve the problems of difficult diffusion of products and inaccessibility of heavy components, and achieve high reactivity, selectivity of aromatics, and good thermal and hydrothermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The preparation method of the composite borosilicate molecular sieve provided by the invention comprises adding β borosilicate molecular sieve as a crystal seed into the reaction mixture for synthesizing ZSM-5 borosilicate molecular sieve, and then performing hydrothermal crystallization.

[0013] The molar ratio of each substance contained in the reaction mixture is (0~0.05) boron source: silicon source: (0~0.2) inorganic base: (0.01~0.15) templating agent: (10~40) water, preferably ( 0.01-0.03) boron source: silicon source: (0.03-0.1) inorganic base: (0.04-0.1) templating agent: (15-25) water. Mix the boron source, silicon source, inorganic base, templating agent, water and β molecular sieve as the seed crystal evenly, carry out hydrothermal crystallization in a closed reactor and recover the product, wherein the boron contained in the boron source compound is B 2 o 3 The silicon contained in the silicon source compound is represented by SiO 2 count.

[0014] In t...

example 1

[0028] 0.64g of borax, 0.4g of NaOH, 4.88g of tetraethylammonium hydroxide solution with a concentration of 25% by mass and 52ml of deionized water were mixed evenly, and 1 g of the β borosilicate molecular sieve prepared in Comparative Example 1 was added under stirring as a seed crystal. After stirring until uniform, add 10g of solid silica gel, stir vigorously, age at 25°C for 2 hours, then transfer to a reaction kettle, crystallize at 140°C for 5 days, and then quickly cool to 30°C. The product is centrifuged and washed until the pH value is 8-9. The obtained solid was dried at 100° C. for 12 hours to obtain a composite borosilicate molecular sieve c whose crystal phase was β / ZSM-5, and its anhydrous chemical composition (calculated by oxide molar ratio) was: 0.5 Na 2 O·B 2 o 3 ·55SiO2 2 , in the composite molecular sieve, the β molecular sieve accounts for 5.4% by mass, and the ZSM-5 molecular sieve accounts for 94.6% by mass. The moles and crystallization conditions o...

example 2

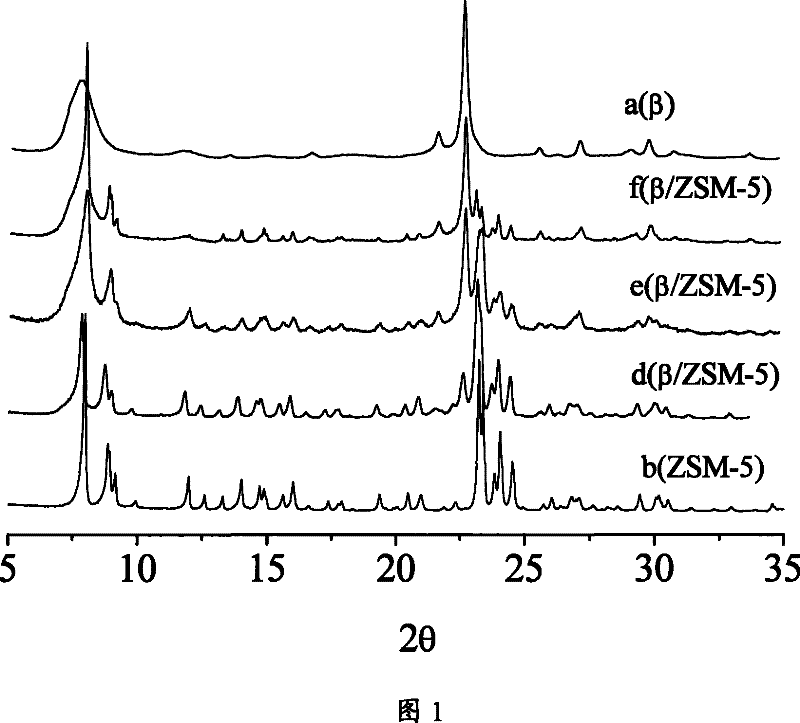

[0030] Mix 0.64g of borax, 0.4g of NaOH, 4.88g of tetraethylammonium hydroxide solution with a concentration of 25% by mass and 52ml of deionized water evenly, add 2g of the β borosilicate molecular sieve prepared in Comparative Example 1 as a seed crystal under stirring, and stir After uniformity, add 10g of solid silica gel, stir vigorously, age at 25°C for 2 hours, then transfer to a reaction kettle, crystallize at 140°C for 5 days, and then quickly cool to 30°C. The product is centrifuged and washed until the pH value is 8-9. The solid was dried at 80°C for 10 hours to obtain a composite borosilicate molecular sieve d with a crystalline phase of β / ZSM-5, and its anhydrous chemical composition (based on the molar ratio of oxides) was: 0.5Na 2 O·B 2 o 3 48SiO2 2 , XRD spectrum see figure 1, in the composite molecular sieve, β molecular sieve accounts for 9% by mass, and ZSM-5 molecular sieve accounts for 91% by mass. The moles and crystallization conditions of each react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com