Production process of shoe fabric formed by flat knitting

A production process and fabric technology, applied in the direction of weft knitting, fabric surface trimming, shaping/stretching ring fabric, etc., can solve the development trend, support and wear resistance that cannot adapt to the structure and color diversification of shoe material fabrics It does not stand out, and the feet cannot be completely fitted, etc., to achieve the effect of rich pattern effect, eliminating cutting process, good wrapping and supporting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment one: a kind of production technology of flat knitting shaped shoe material fabric, comprises following processing steps:

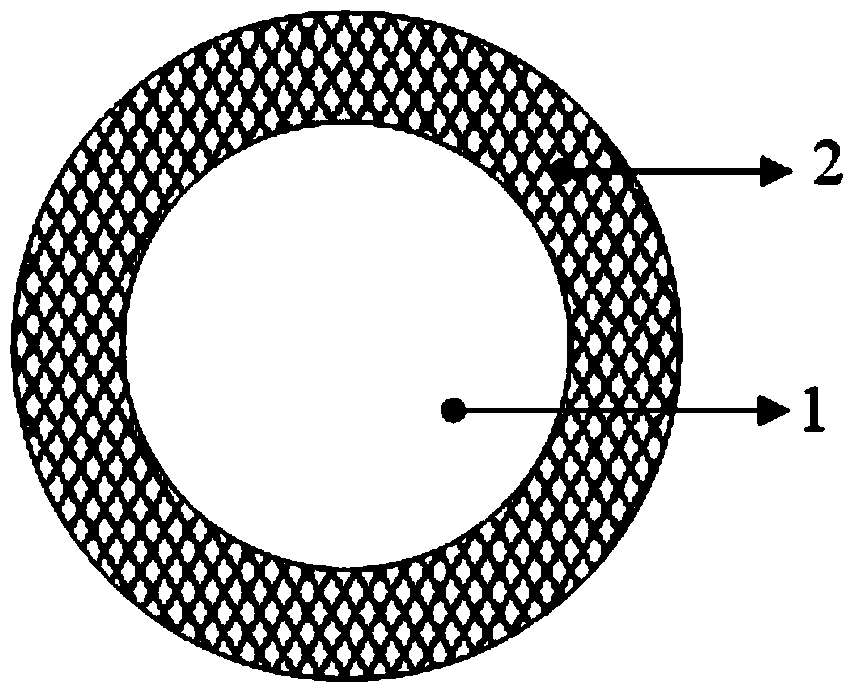

[0024] (1) Raw materials: choose 100D low-melting point skin-core DTY colored yarn and 150D polyester FDY colored yarn as raw materials; the structure of low-melting point skin-core DTY colored yarn is as follows: figure 1 As shown, it includes a core layer 1 and a skin layer 2, the core layer 1 is polyester yarn, and the skin layer 2 is low-melting point polyester;

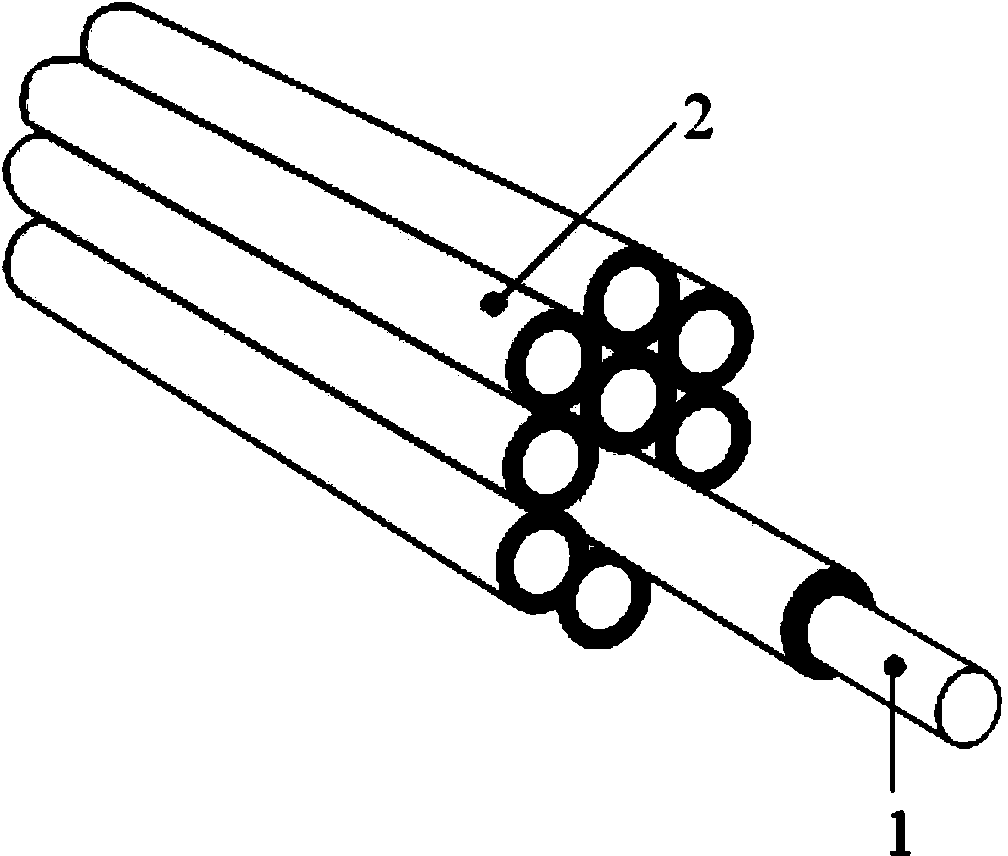

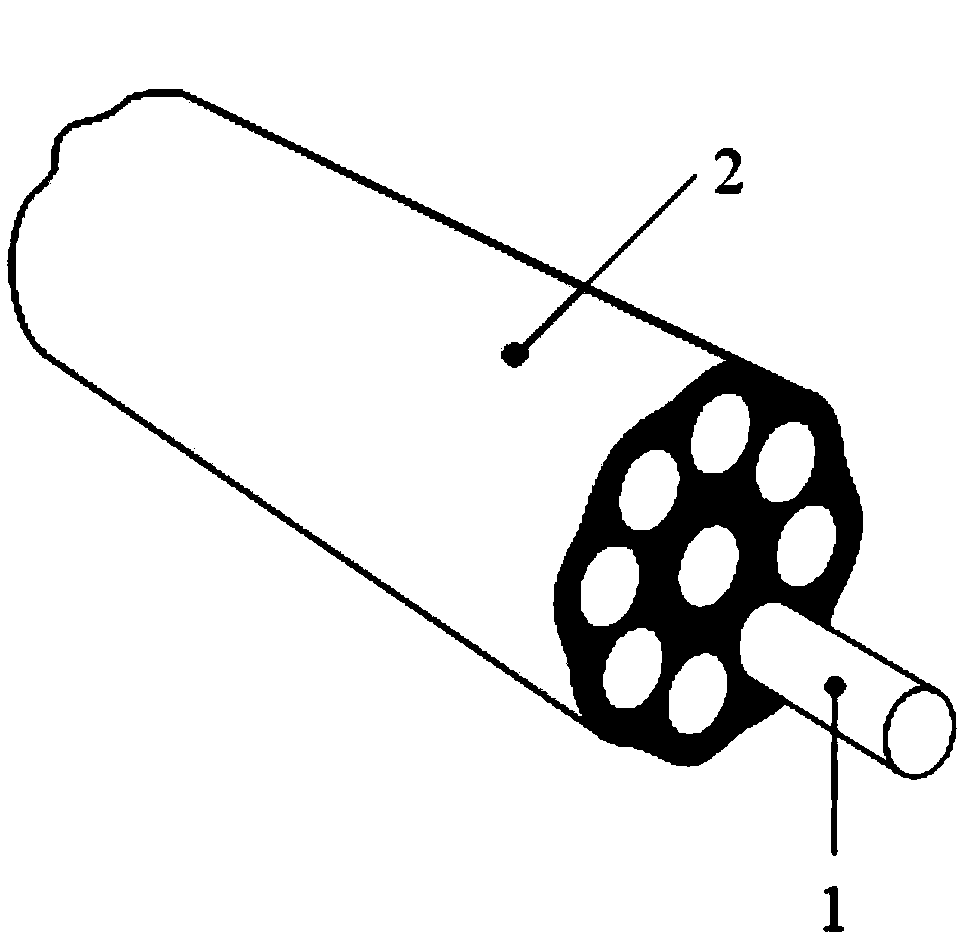

[0025] (2) Combine 3 low-melting-point sheath-core DTY colored yarns and 3 polyester FDY colored yarns to obtain yarns; use the obtained yarns to weave on a computerized flat knitting machine, and the yarns form interlaced coils (such as Pic 4-1 As shown), through the current horizontal knitting process such as retracting and retracting needles and partial knitting, we can obtain such Figure 5 Shoe material fabric shown, no cutting required;

[0026] (3) Drying and finis...

Embodiment 2

[0027] Embodiment two: a kind of production technology of flat knitting forming shoe material fabric, comprises following process steps:

[0028] (1) Raw materials: choose 100D low-melting point skin-core DTY colored yarn and 150D polyester FDY colored yarn as raw materials; the structure of low-melting point skin-core DTY colored yarn is as follows: figure 1 As shown, it includes a core layer 1 and a skin layer 2, the core layer 1 is polyester yarn, and the skin layer 2 is low-melting point polyester;

[0029] (2) Combine 4 low-melting-point sheath-core DTY colored yarns and 2 polyester FDY colored yarns to obtain yarns; use the obtained yarns to weave on a computerized flat knitting machine, and the yarns form interlaced coils (such as Pic 4-1 As shown), through the current horizontal knitting process such as retracting and retracting needles and partial knitting, we can obtain such Figure 5 Shoe material fabric shown, no cutting required;

[0030] (3) Drying and finishi...

Embodiment 3

[0031] Embodiment three: a kind of production technology of horizontal knitting forming shoe material fabric, comprises following process steps:

[0032] (1) Raw materials: choose 100D low-melting point skin-core DTY colored yarn and 150D polyester FDY colored yarn as raw materials; the structure of low-melting point skin-core DTY colored yarn is as follows: figure 1 As shown, it includes a core layer 1 and a skin layer 2, the core layer 1 is polyester yarn, and the skin layer 2 is low-melting point polyester;

[0033] (2) Combine 4 low-melting-point sheath-core DTY colored yarns and 2 polyester FDY colored yarns to obtain yarns; use the obtained yarns to weave on a computerized flat knitting machine, and the yarns form interlaced coils (such as Pic 4-1 As shown), through the current horizontal knitting process such as retracting and retracting needles and partial knitting, we can obtain such Figure 5 Shoe material fabric shown, no cutting required;

[0034] (3) Drying and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com