Mechanical sealing device

A technology of mechanical sealing device and static ring, which is applied to mechanical equipment, components of pumping device for elastic fluid, machine/engine, etc. Affect the rotation of the moving ring, etc., to enhance the friction, ensure the sealing effect, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

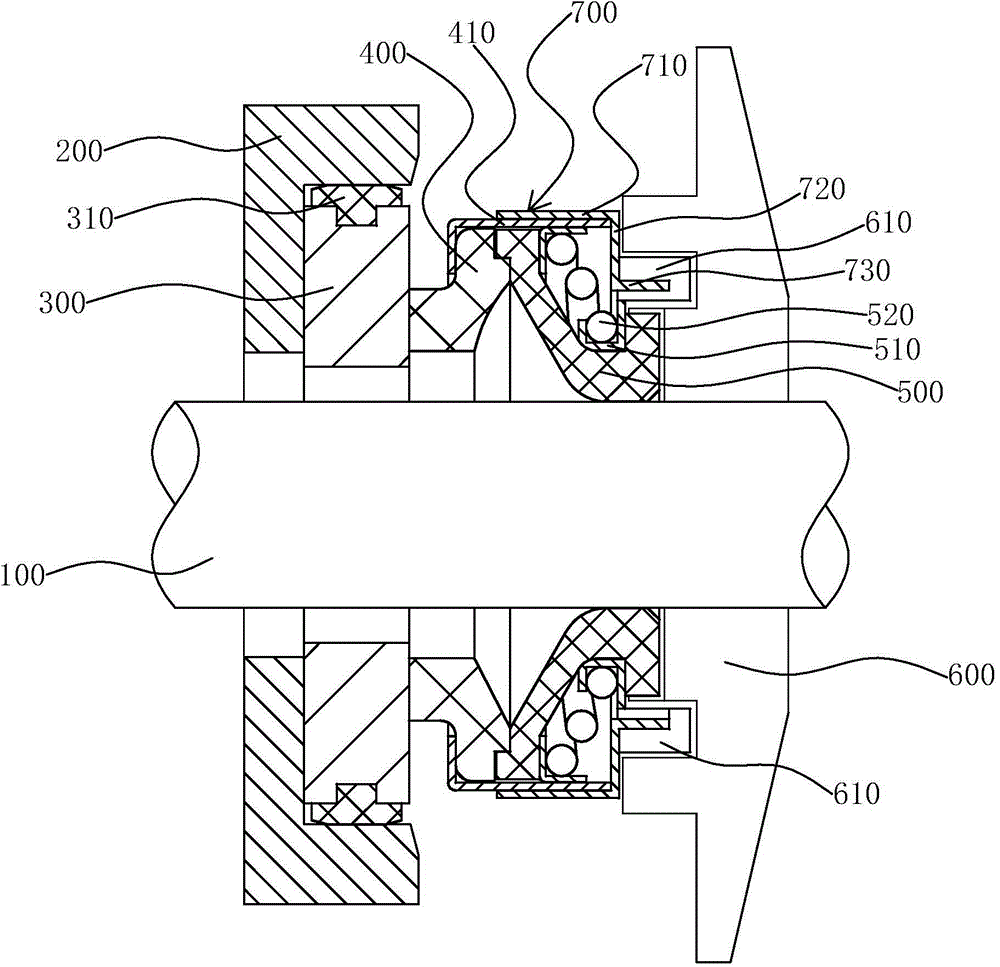

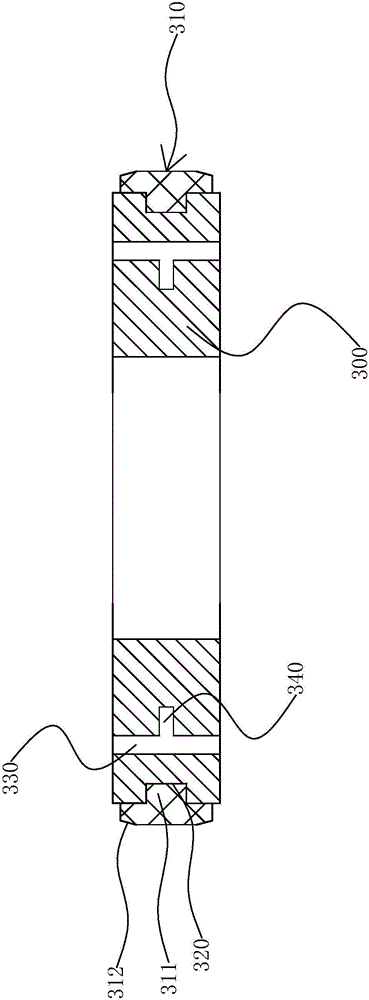

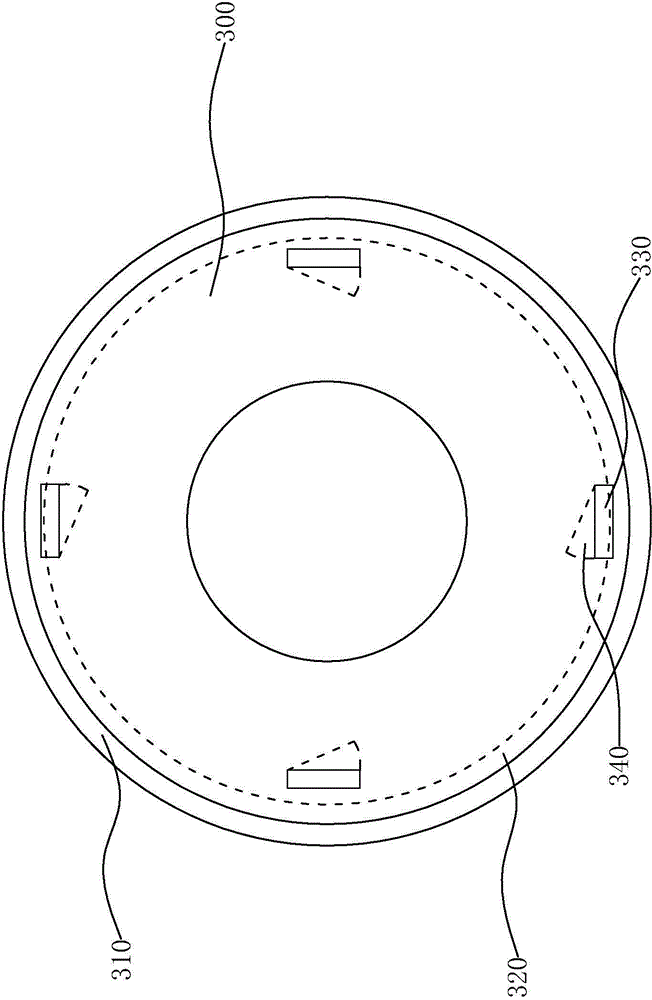

[0032] like figure 1 As shown, a mechanical sealing device of the present invention includes a pump shaft 100, on which a pump chamber gland 200 perpendicular to the pump shaft 100, a static ring 300, a moving ring 400, a spring bracket 500, and an impeller 600 are sequentially installed. .

[0033] Further, a concave annular groove is axially opened on the end surface of the pump chamber gland 200 opposite to the moving ring 400, the static ring 300 is installed in the concave annular groove, and the two ends of the static ring 300 are respectively connected with the concave annular groove and the moving ring. 400 is close to one end face, and the end faces of the two ends of the static ring 300 are respectively polished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com