Manual reversing valve

A technology for manual reversing valves and handles, which is applied to fluid pressure actuators, servo motor components, mechanical equipment, etc. It can solve the problems of laborious operation and incompletely humanized operation methods, and achieve cleanliness and safety. Sexual prolongation, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

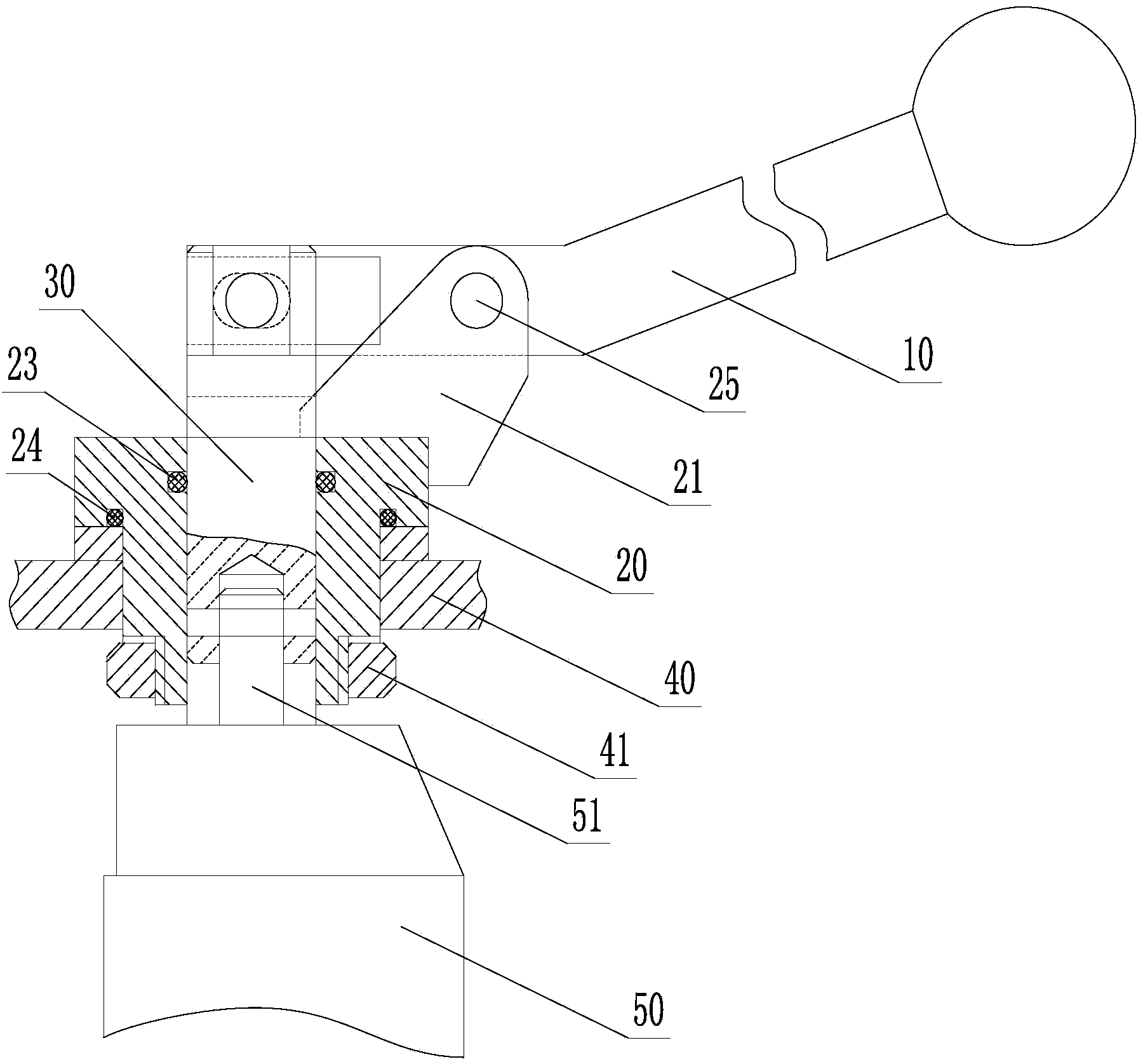

[0026] The structure of the manual reversing valve of the present invention is as follows: figure 1 As shown, it includes: handle 10, support 20 and support frame 21, push rod 30, valve body 50 and pin shaft 51, when installing the manual reversing valve in the hydraulic system, it also includes installation panel 40, fixing nut 41 and other components.

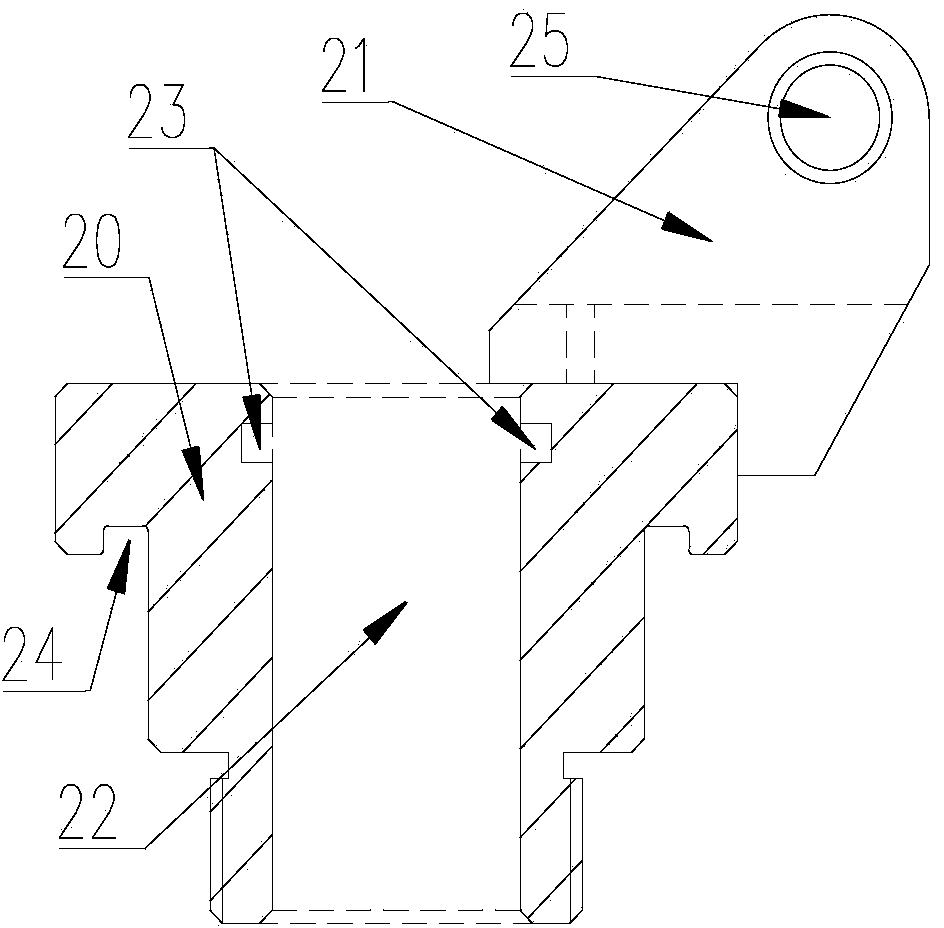

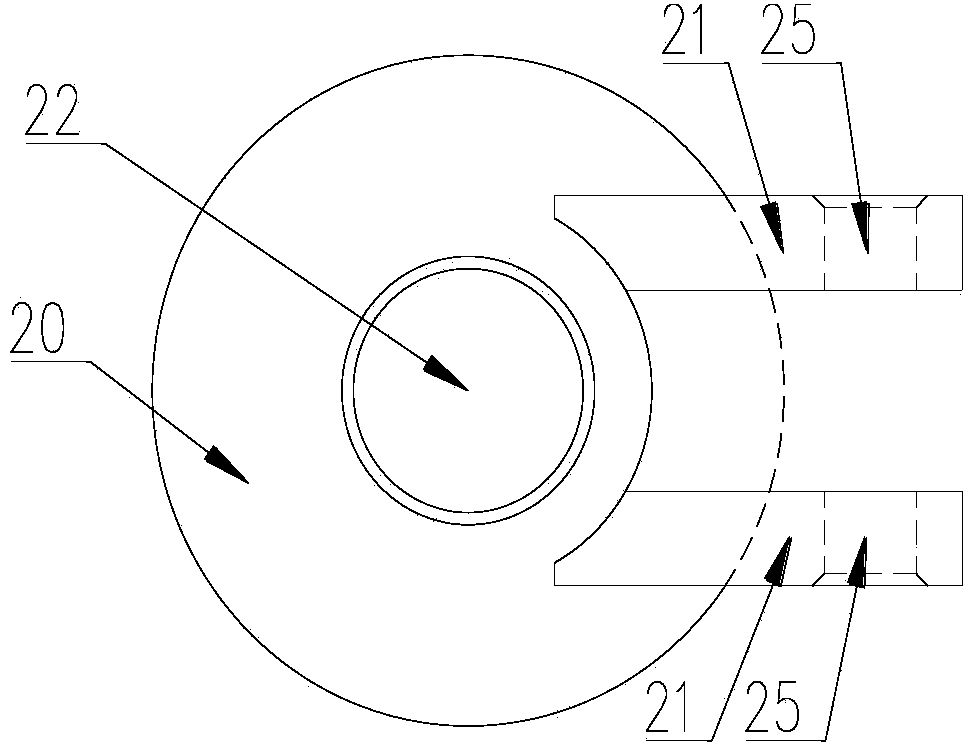

[0027] Support structure such as figure 2 with image 3 As shown, there is a support hole 22 on the support 20, the push rod 30 is prevented in the support hole 22, and the inner diameter of the support hole 22 matches the outer diameter of the push rod 30, the support frame 21 is set on the support 20, two pieces Support holes 25 are respectively provided on the support frame 21 . In a preferred solution, a first groove 23 is also arranged in the seat hole 22, and a sealing ring is arranged in the first groove 23. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com