Device for venting gear units

一种变速器、变速器壳体的技术,应用在机械设备、传动装置零件、皮带/链条/齿轮等方向,能够解决变速器轴机械加工有要求、限制扭矩载荷、耗费成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

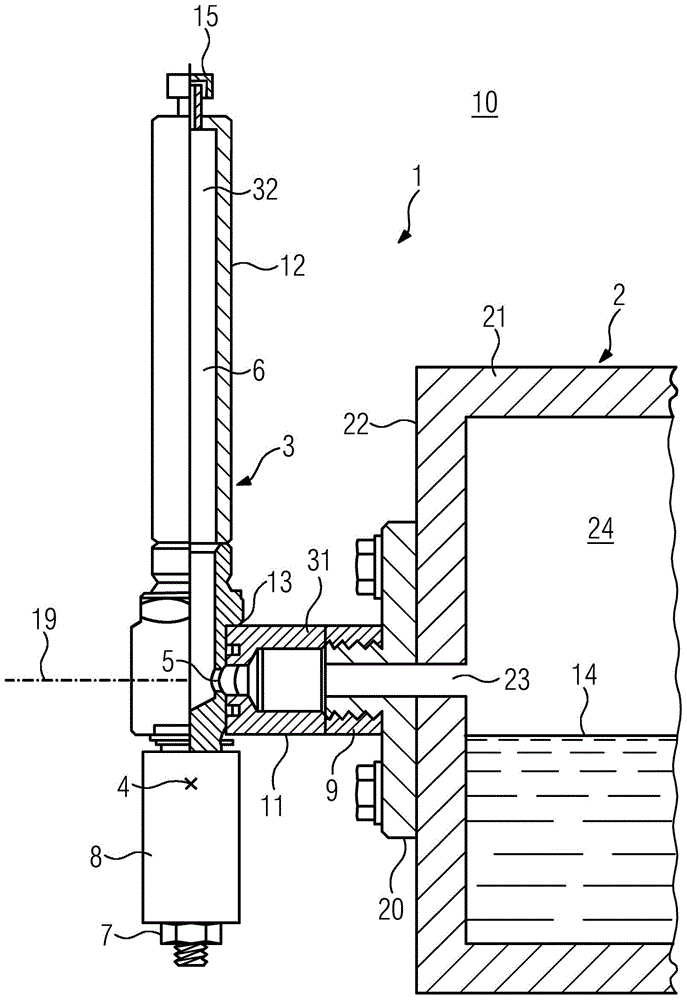

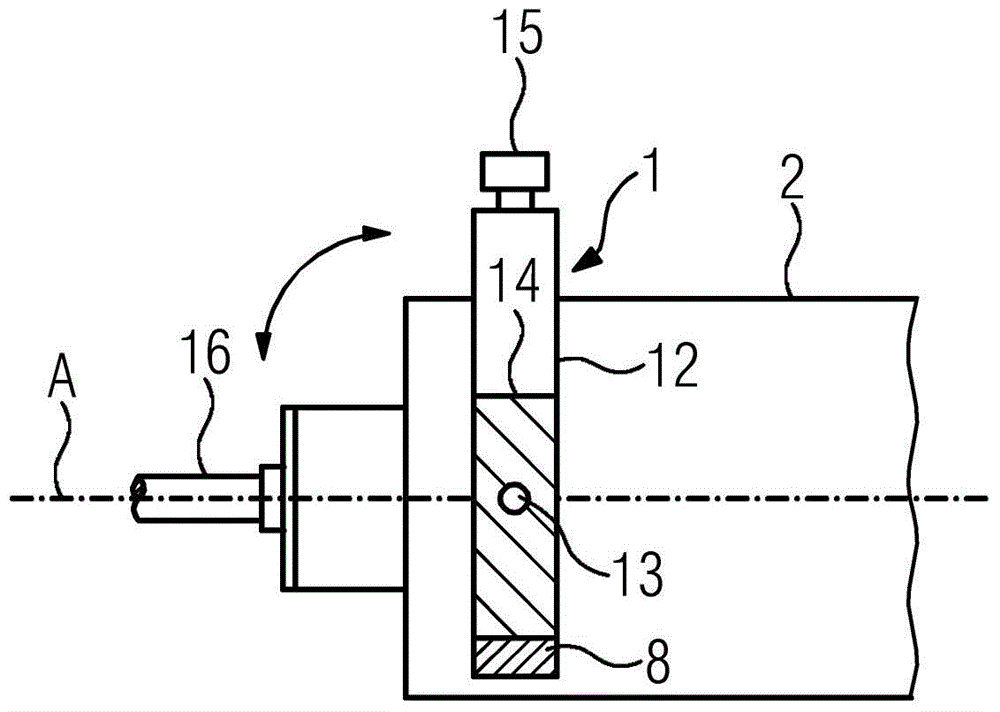

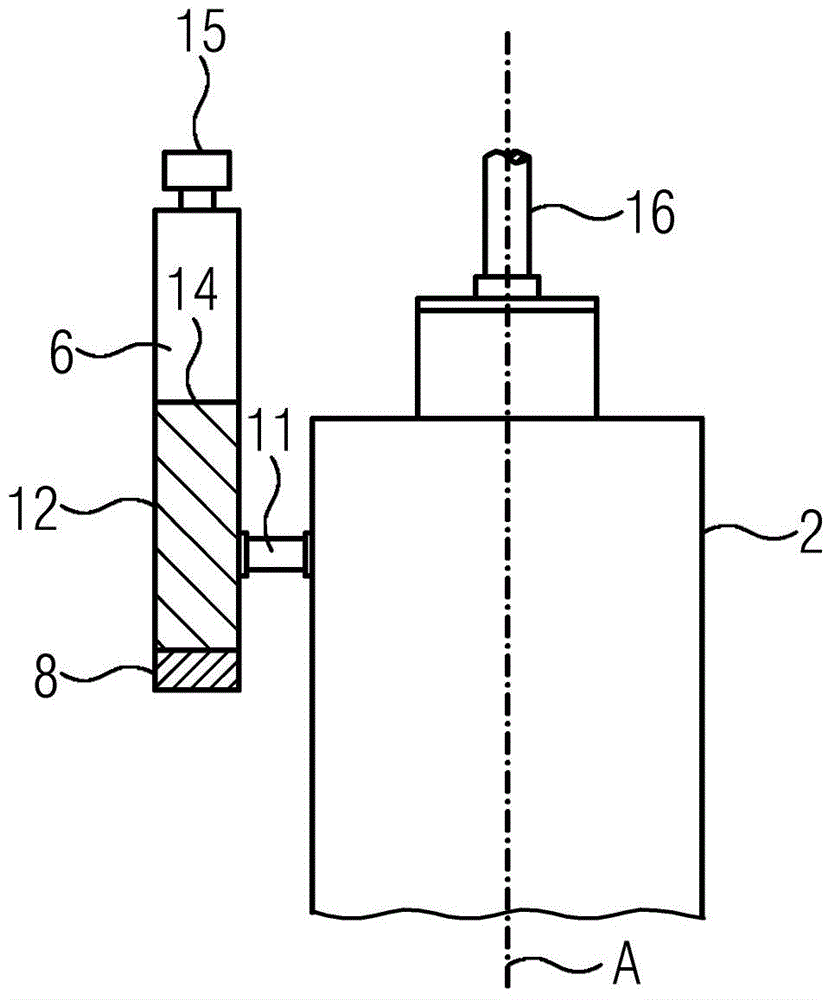

[0037] figure 1 A device 1 for venting a transmission 2 operated with oil immersion lubrication is shown. The device 1 comprises a tubular first part 11 and a tubular second part 12 which is substantially longer than the first part 11 . The second part 12 comprises an elongated thin-walled tube which is used as the compensation container 6 . On one end of the second part 12 a thick steel plate 8 is carried, which is firmly connected to the compensating container 6 by means of a screw arrangement 7 .

[0038] At its transmission-side end, the first part 11 has an internal thread 9 which is screwed securely onto an external thread of a screw flange 20 which is arranged on an outer side 22 of the transmission 2 . The two parts 11 and 12 are connected and movable relative to each other by means of a hinge 13 . The hinge 13 is designed as an axially rotating sleeve, for example a linearly rotating sleeve supported on a ball bearing, that is to say that the second part 12 can rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com