High-pressure container opening nozzle structure suitable for rapid opening and closing

A high-pressure container and connection structure technology, which is applied to pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve the problems of low opening and closing efficiency and poor sealing effect, and achieve high opening and closing efficiency, simple loading and unloading, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

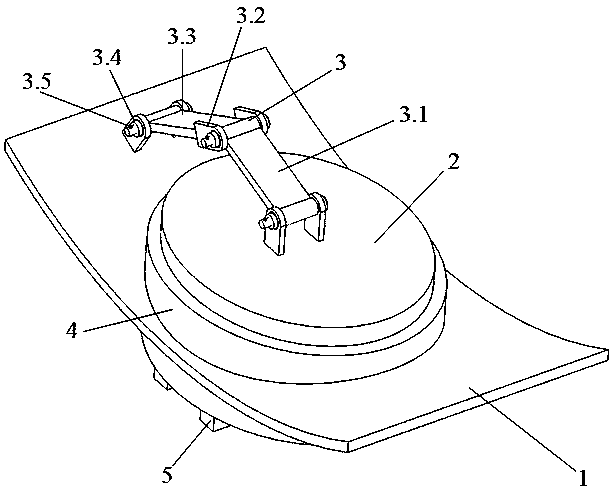

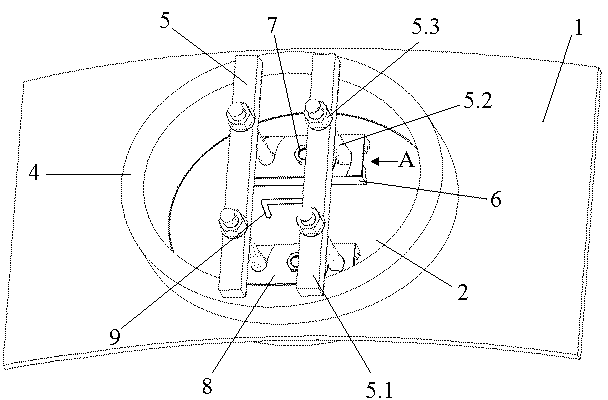

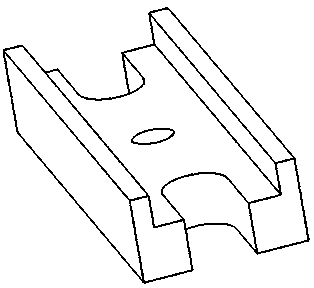

[0024] Such as figure 1 , figure 2 As shown, the present invention includes a connecting pipe 4, a cover plate 2, a connecting rod mechanism 3 and a tensioning mechanism 5. The opening of the housing 1 of the high-pressure vessel is provided with a connecting pipe 4, and the inner end surface of the connecting pipe 4 is in sealing contact with the outer surface of the cover plate 2. The middle part of the outer surface of the cover plate 2 is fixedly connected with two U-shaped plates 6 and a handle 9 in parallel. The outer sides of the two U-shaped plates 6 are respectively equipped with a guide plate 8, and the centers of the guide plate 8 and the U-shaped plate 6 pass through the screw 7. Rotational connection; the inner surface of the cover plate 2 is connected to the inner wall of the housing 1 through a movable hinged link mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com