Support piece structure for petroleum pipeline support frame

A technology of oil pipelines and support frames, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of poor practicability and non-detachable pipeline supports, and achieve convenient loading and unloading, simple structure, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

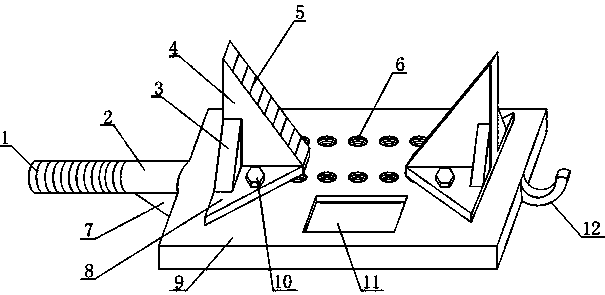

[0016] Such as figure 1 The shown support structure for the oil pipeline support frame includes a connecting plate 9 and two triangular clamping plates symmetrically arranged on the upper end of the connecting plate 9. The left end of the connecting plate 9 is horizontally connected with a threaded column 2, and the threaded The left end of the column 2 is provided with an external thread 1, and the connecting plate 9 is also provided with two rows of equidistantly arranged threaded through holes 6 in the vertical plane; Vertical right-angle clamp 4, said base plate 8 is fixed on the connecting plate 9 upper end by the bolt 10 that is positioned at vertical right-angle clamp 4 both sides, the oblique of the vertical right-angle clamp 4 of described two triangular clamps The sides are set relative to each other.

[0017] When the present embodiment is in use, the distance between the two triangular clamps is determined according to the diameter of the oil pipeline, and after d...

Embodiment 2

[0019] In this embodiment, the following structure is added on the basis of Embodiment 1: the lower end of the connection between the threaded column 2 and the connecting plate 9 is also welded with a reinforcing plate 7 .

[0020] In this embodiment, in order to strengthen the connection strength between the threaded column 2 and the connection plate 9, and prevent the connection plate 9 from being broken by the gravity of the pipeline and the connection between the threaded column 2, a reinforcing plate 7 is welded at the lower end of the connection between the threaded column 2 and the connection plate 9. , Strengthen the strength of the connection between the two, reduce safety hazards, and prolong the service life of the support.

Embodiment 3

[0022] This embodiment is further optimized on the basis of embodiment 1 or embodiment 2, specifically: the hypotenuses of the two vertical right-angle clamps 4 are both provided with anti-slip grooves 5 .

[0023] In this embodiment, since the pipeline is directly placed in the space between the hypotenuses of the two vertical right-angle clamps 4, in order to increase the stability of the pipeline and avoid pipeline connection leakage or other safety hazards caused by the rotation of the pipeline under the action of external force, Therefore, anti-skid grooves 5 are provided on the hypotenuses of the two vertical right-angle clamps 4 to strengthen the friction between the pipeline and the hypotenuses, so as to achieve firm positioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com