Test Structure for Residual Stress of Thin Film Silicon Material on Insulating Substrate

A technology for testing structures on an insulating substrate, applied in the direction of applying a stable bending force to test material strength, measuring force, and measuring devices, which can solve the problems of uncertain and unstable device design and performance prediction, and achieve the test process And the effect of stable test parameter value, simple test method and simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

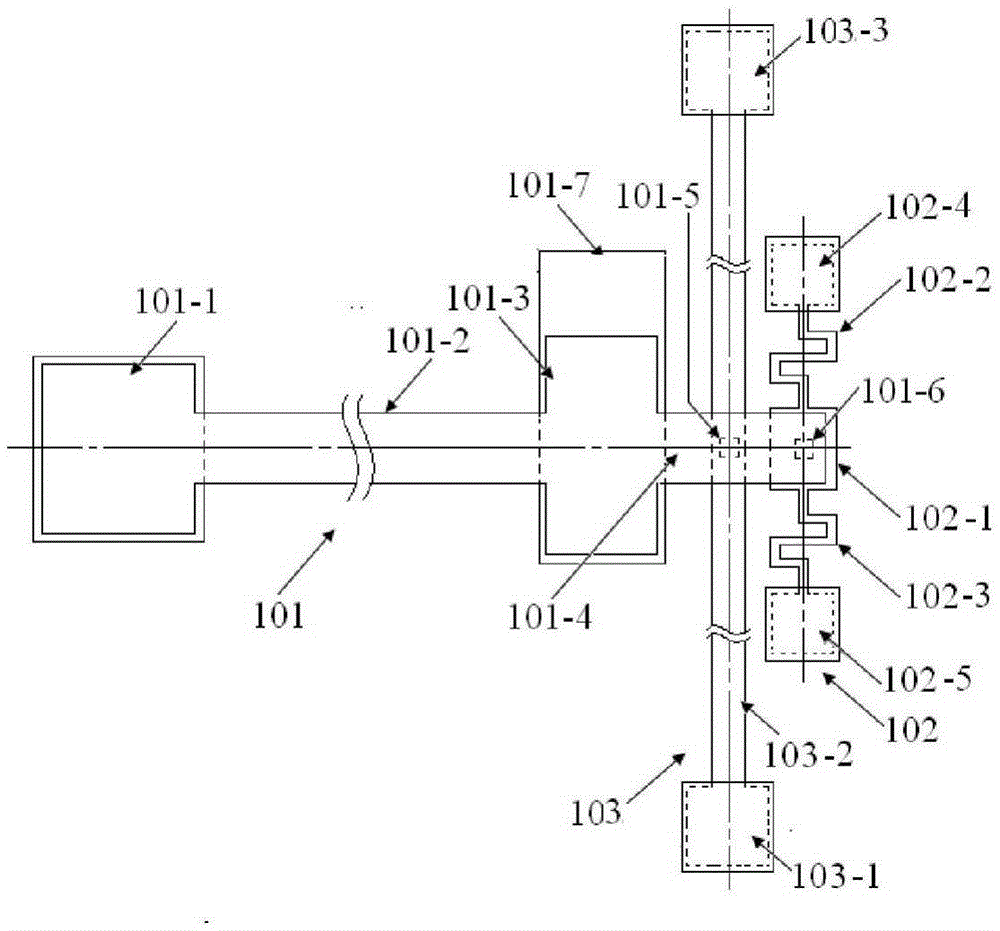

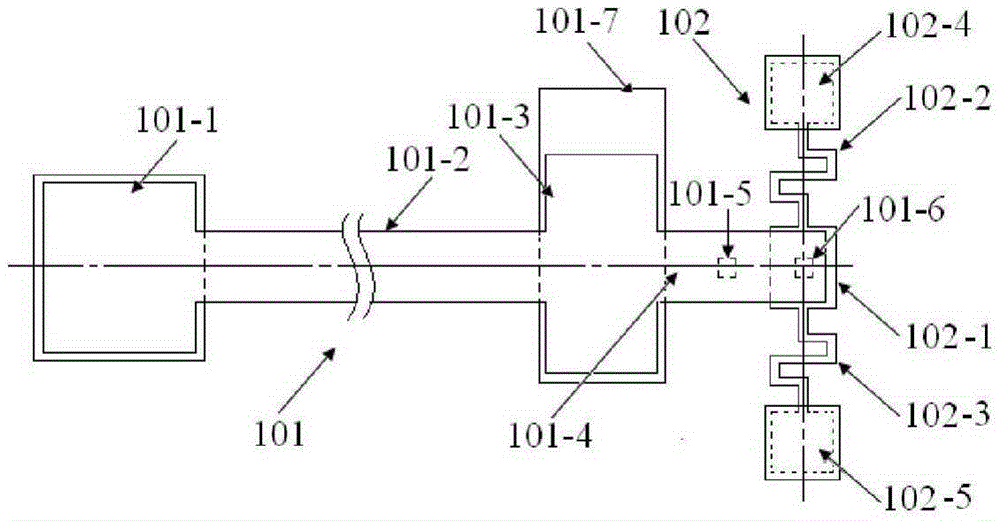

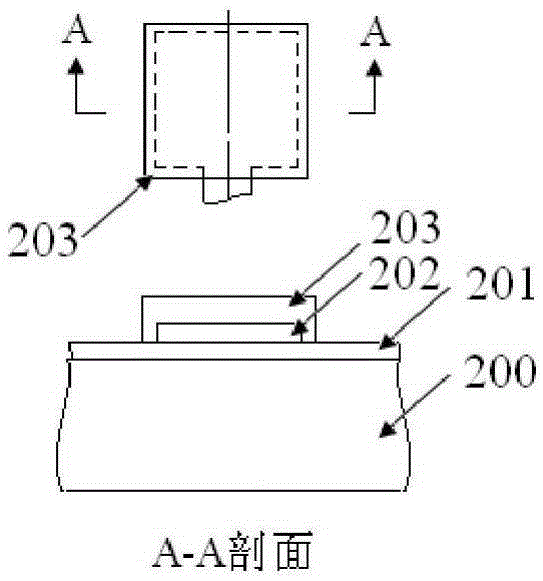

[0029] Attached below figure 1 , figure 2 and image 3 The present invention will be further described.

[0030] The invention provides a test structure for measuring the residual stress of thin film silicon material on an insulating substrate. The test structure consists of two sets of structures. The first set of structures such as figure 1 As shown, the test structure is composed of two groups of structures; wherein the first group of structures consists of a polysilicon cantilever beam 101, a thin-film silicon double-ended fixed beam 103 and a backing plate 102 made of thin-film silicon; the second group of structures consists of A polysilicon cantilever beam 101 and a backing plate 102 made of thin film silicon;

[0031] The polysilicon cantilever beam 101 of the first group structure is formed by connecting the first anchor region 101-1, the slender beam 101-2, the wide beam 101-3 as the upper electrode, and the thin short beam 101-4 from left to right , on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com