Calculation method and device for product assembly deviation

A calculation method and product technology, applied in the fields of calculation, instrumentation, electrical and digital data processing, etc., can solve the problems that affect the cumulative calculation of assembly deviations, and cannot support the search for assembly deviation transmission routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

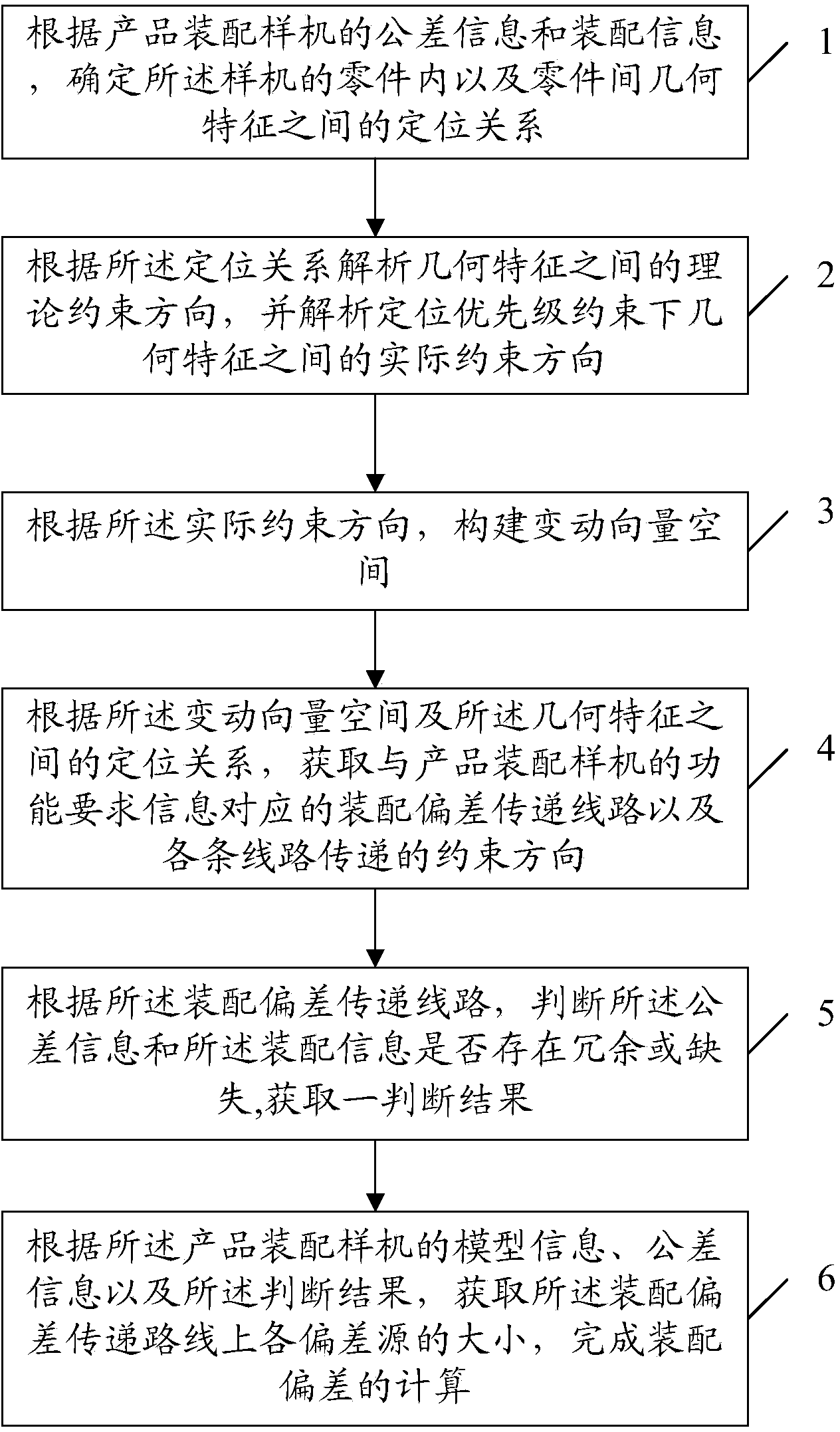

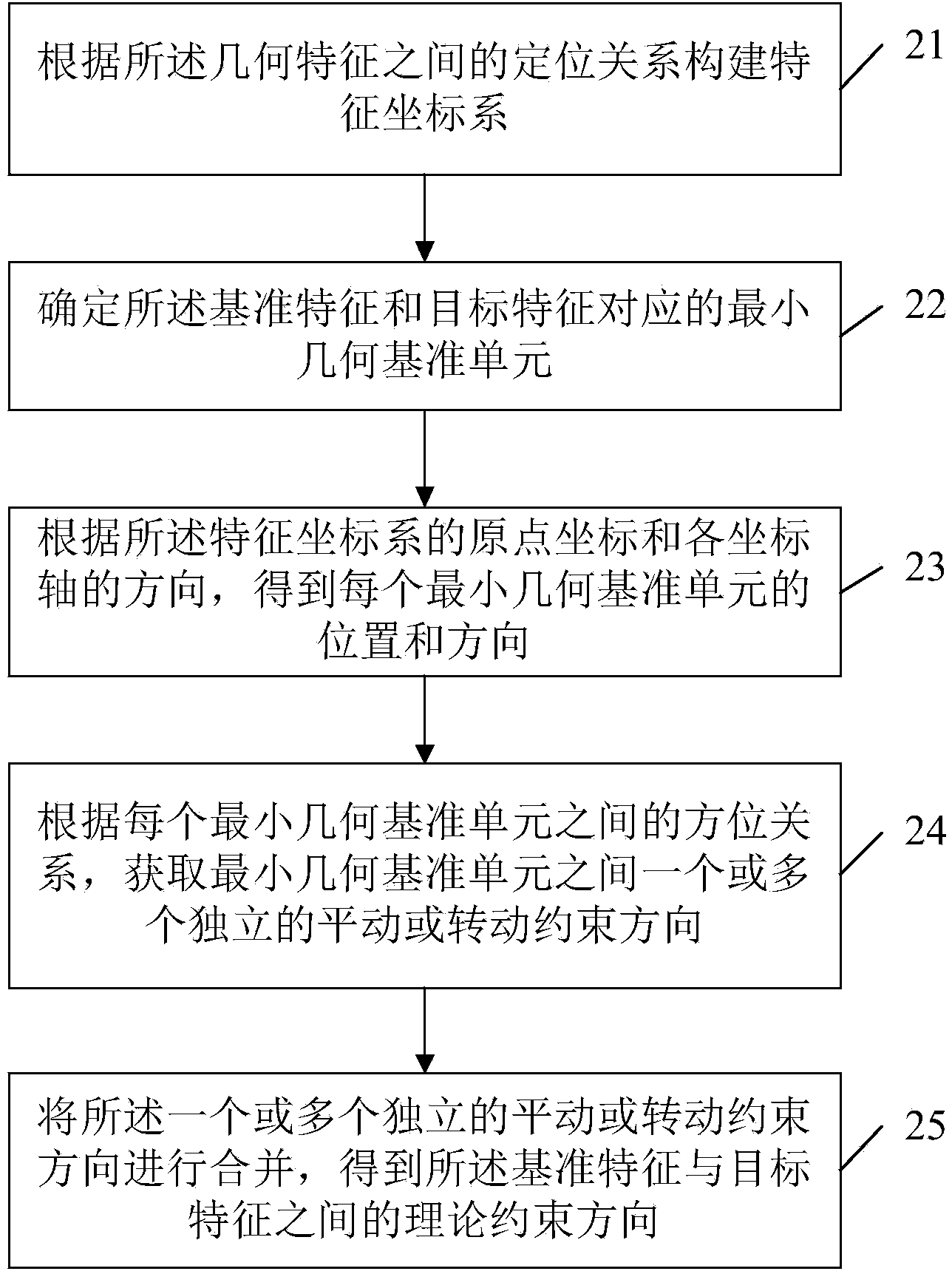

[0086] The present invention aims at the problems of poor versatility and low degree of automation in the assembly deviation transfer route search in the prior art in the process of geometric tolerance design, and provides a method and device for calculating product assembly deviation, according to the tolerance information and assembly information of the product assembly prototype and model information, extract the positioning relationship between geometric features, the theoretical constraint direction and the actual constraint direction, construct a change vector space, and obtain assembly deviation transfer information through the change vector space, and at the same time, according to the tolerance information and assembly information redundancy or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com