110 kv line two-circuit iron tower equipotential swing ladder

A double-circuit, equipotential technology, applied to overhead lines/cable equipment, ladders, buildings, etc., can solve the problems of inability to carry out live work, fail to meet the requirements of combined gaps, and fail to meet safety requirements, etc., to improve the quality of power supply services , Guarantee operation safety and reduce the effect of less power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

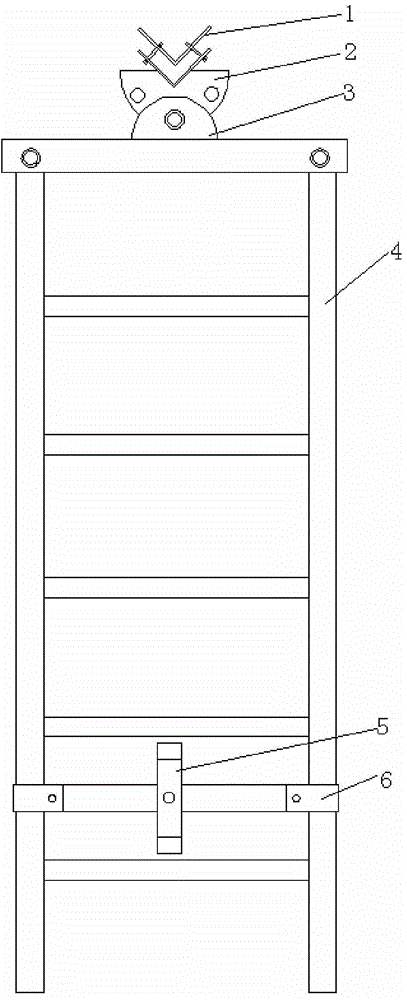

[0013] like figure 1 As shown, the present invention is a 110kV line double-circuit iron tower equipotential swing ladder, including an insulating hard ladder 4, and its length is required to be no less than 3m. A connecting rod is fixedly installed on the top of the insulating hard ladder 4, specifically, a casing is respectively provided at both ends of the connecting rod, and one end of the insulating hard ladder 4 extends into the casing and passes through the fastener and the casing. Fixed connection.

[0014] A U-shaped chuck 3 is arranged in the middle of the connecting rod, and a mounting hole is respectively opened on the opposite ends of the U-shaped chuck 3, and a half-circular plate 2 is also included. There are 3 through holes on the top, and the semicircular plate 2 is inserted into the middle of the U-shaped chuck 3 through any one of the through holes and fixed on the mounting hole of the U-shaped chuck 3 with fasteners. The interval between any two adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com