A Method for Optimizing Structural Parameters of Torque Motor

A technology of structural parameters and optimization methods, applied in the control of generators, motor generators, electronic commutation motor control, etc., can solve the problems of long labor time, excellent characteristics of the objective function no longer exist, and large calculation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

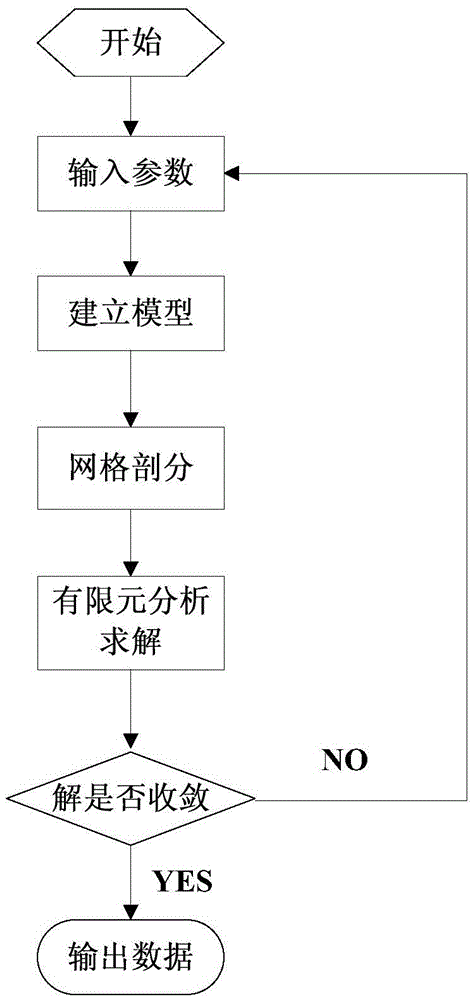

[0054] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

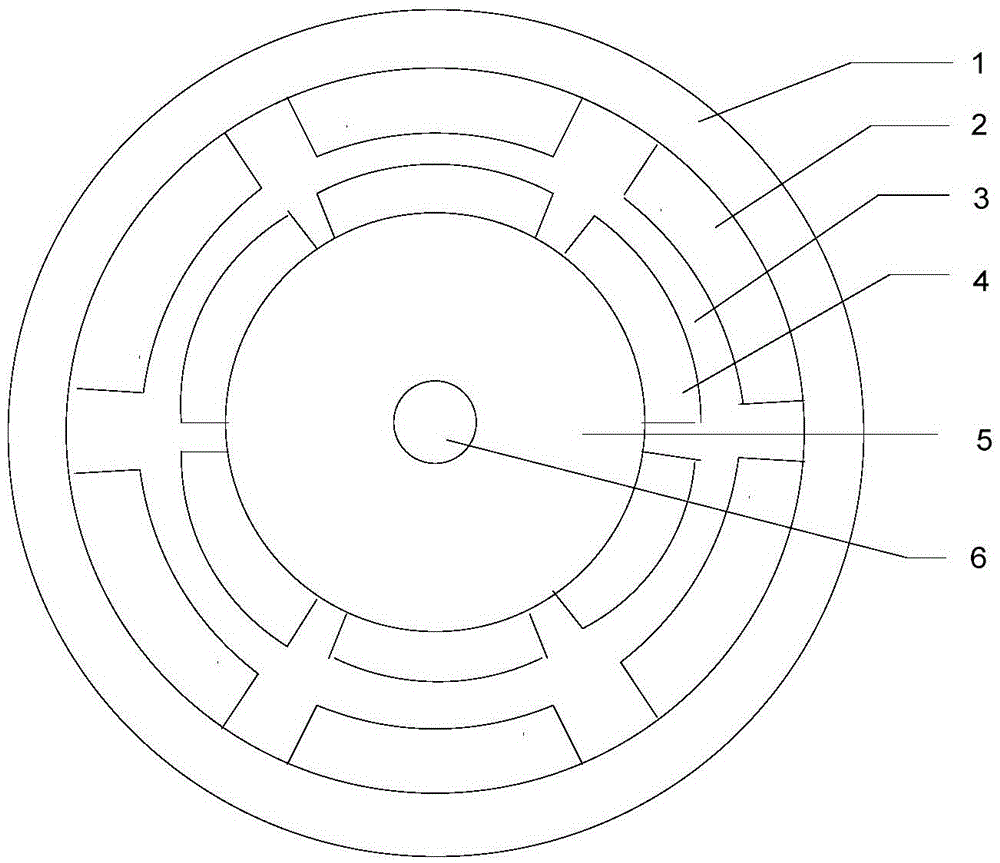

[0055] In the embodiment of the invention, the motor adopts a novel torque motor (such as figure 2 shown), the motor stator and rotor materials are 10 steel, the stator and rotor pole materials are NdFeBN50, (Br is remanence) B r =1.425T, (Hc is the coercive force) H c =907KA / m.

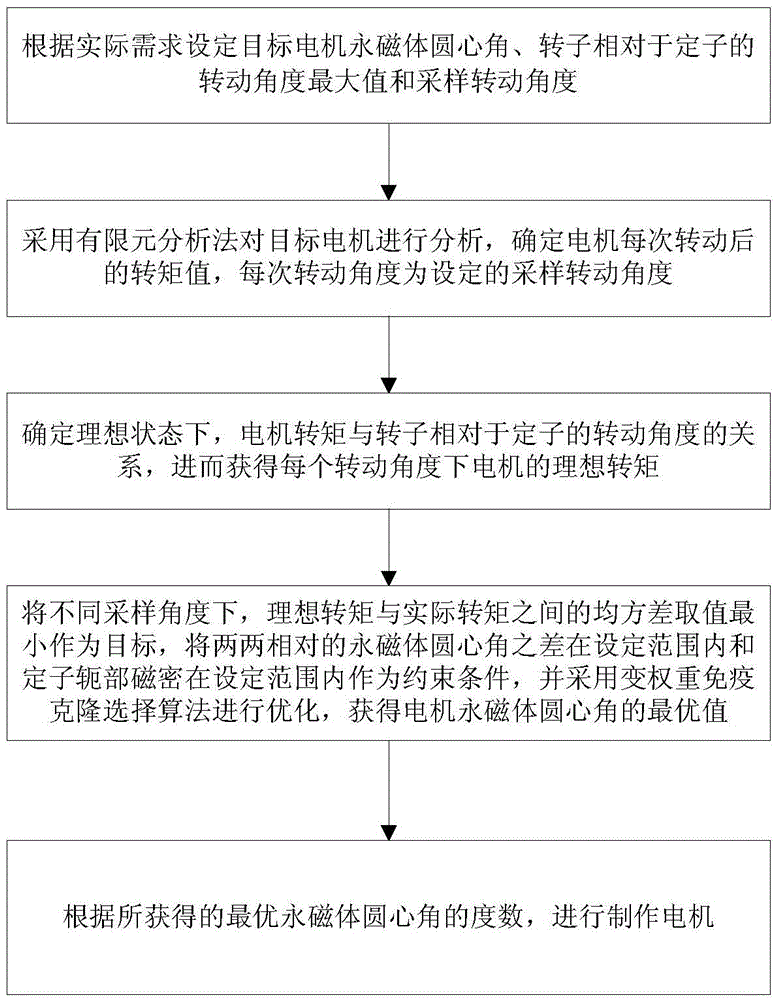

[0056] In the embodiment of the present invention, the structure parameter optimization method of the torque motor, the flow chart of the method is as follows figure 1 shown, including the following steps:

[0057] Step 1. Set the central angle of the permanent magnet of the target motor, the maximum rotation angle of the rotor relative to the stator, and the sampling rotation angle according to actual needs;

[0058] In the embodiment of the present invention, the range of central angles of the six permanent magnets of the target motor is x=[20°, 50°]; the maximum rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com