Oil pipe steam purging device

A steam and oil pipe technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of construction personnel injury, high risk, high cleanliness requirements, etc. Safety and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

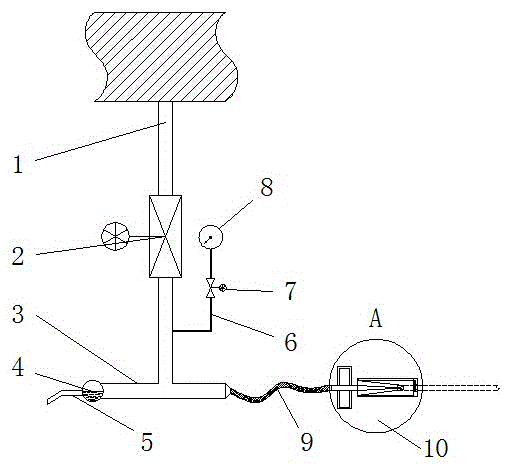

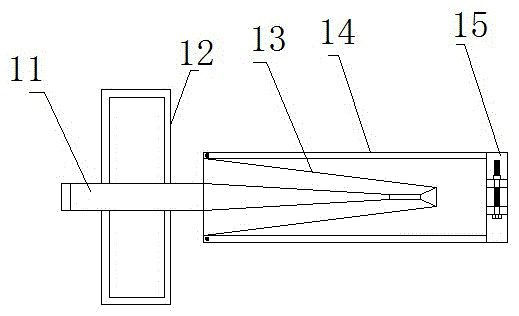

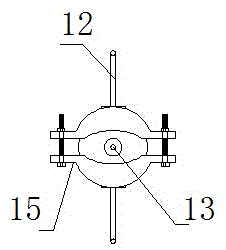

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0015] An oil pipe steam purging device of the present invention comprises a steam supply pipe 1, one end of the steam supply pipe 1 is connected with a steam source, and the other end is connected with a steam outlet pipe 3, and the middle part of the steam outlet pipe 3 is perpendicular to the steam supply pipe 1 One end of the steam outlet pipe 3 is provided with a drain pipe 5 with an automatic drain valve 4, and the other end is connected with a depressurization speed-up spray gun 10; Steam pipe 11, the rear end of the steam inlet pipe 11 is connected with the steam outlet pipe 3, and the front end is provided with a conical steam nozzle 13 that is thin before and thick at the rear. The cavity is conical with thin front and thick at the back, the cavity in the middle section is cylindrical, and the cavity in the front section is conical with thick front and thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com