Mould and method for manufacturing bimetal plain thrust sliding bearing blank and manufacturing method thereof

The invention relates to a sliding bearing and bimetal technology, which is applied in the field of centrifugal casting to prepare a mold for a bimetal thrust sliding bearing blank and its preparation field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

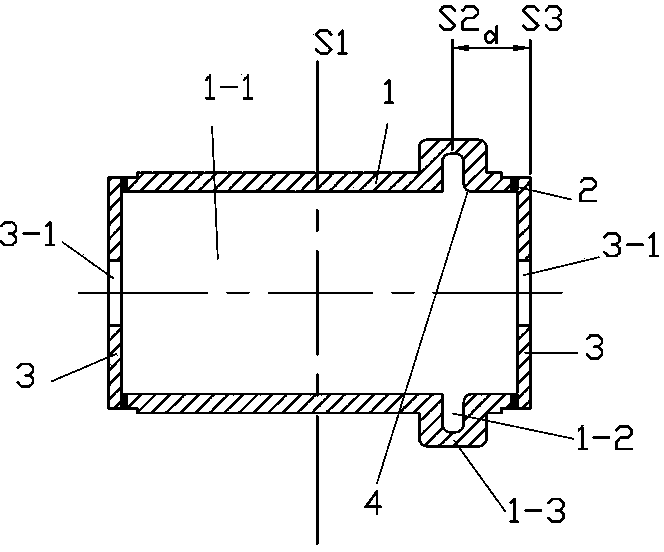

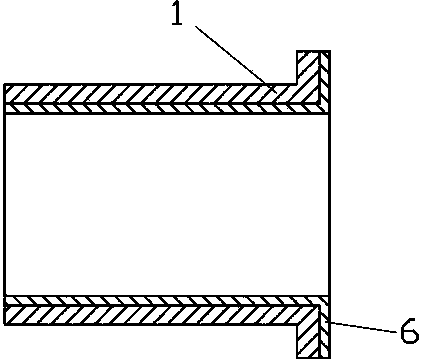

[0030] Such as figure 1 As shown, a bimetallic thrust sliding bearing blank preparation mold of the present invention includes a steel billet 1 and an asbestos board 3, the steel billet 1 has an inner hole 1-1 and an annular groove 1-2, and the annular groove 1- 2 is arranged on the hole wall of the inner hole 1-1, the inner hole 1-1 communicates with the annular groove 1-2, the two ends of the steel billet 1 are adhered with the corresponding asbestos board 3 through the high temperature resistant adhesive 2, The asbestos board 3 has a central hole 3 - 1 , and the central hole 3 - 1 of the asbestos board 3 communicates with the inner hole 1 - 1 of the billet 1 .

[0031] The annular groove 1-2 is arranged at one end of the steel billet 1 away from the center section S1 of the steel billet, the cross section of the annular groove 1-2 of the steel billet 1 is U-shaped, and the U-shaped opening of the annular groove 1-2 is far away from One edge of the central section S1 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com