General welding clamp for producing base plates of prototype vehicle and derived vehicle types of prototype vehicle

A technology for welding fixtures and car models, which is applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of increasing production costs, achieve high positioning accuracy, and ensure dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

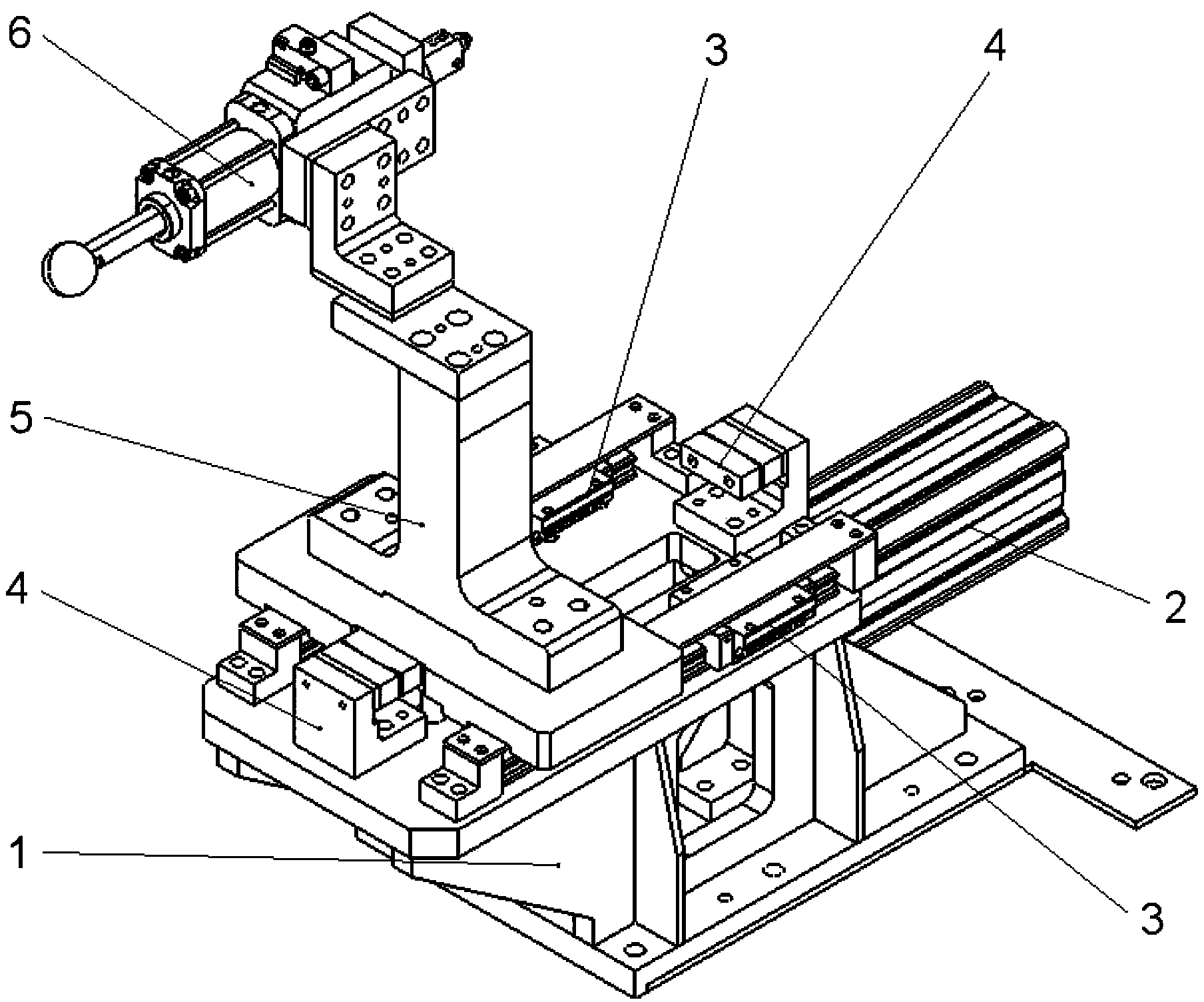

[0015] Such as figure 1 As shown, a general welding jig for producing the base plate of the prototype car and its derivative models is composed of three parts: a fixed base 1, a switching mechanism and a positioning mechanism. Wherein, the switching mechanism includes a linear cylinder 2 arranged on a fixed base 1, a guide rail chute assembly 3 and two switching limit blocks 4, and the positioning mechanism includes a cylinder fixing bracket 5 and a positioning cylinder 6 arranged on the cylinder fixing bracket 5 .

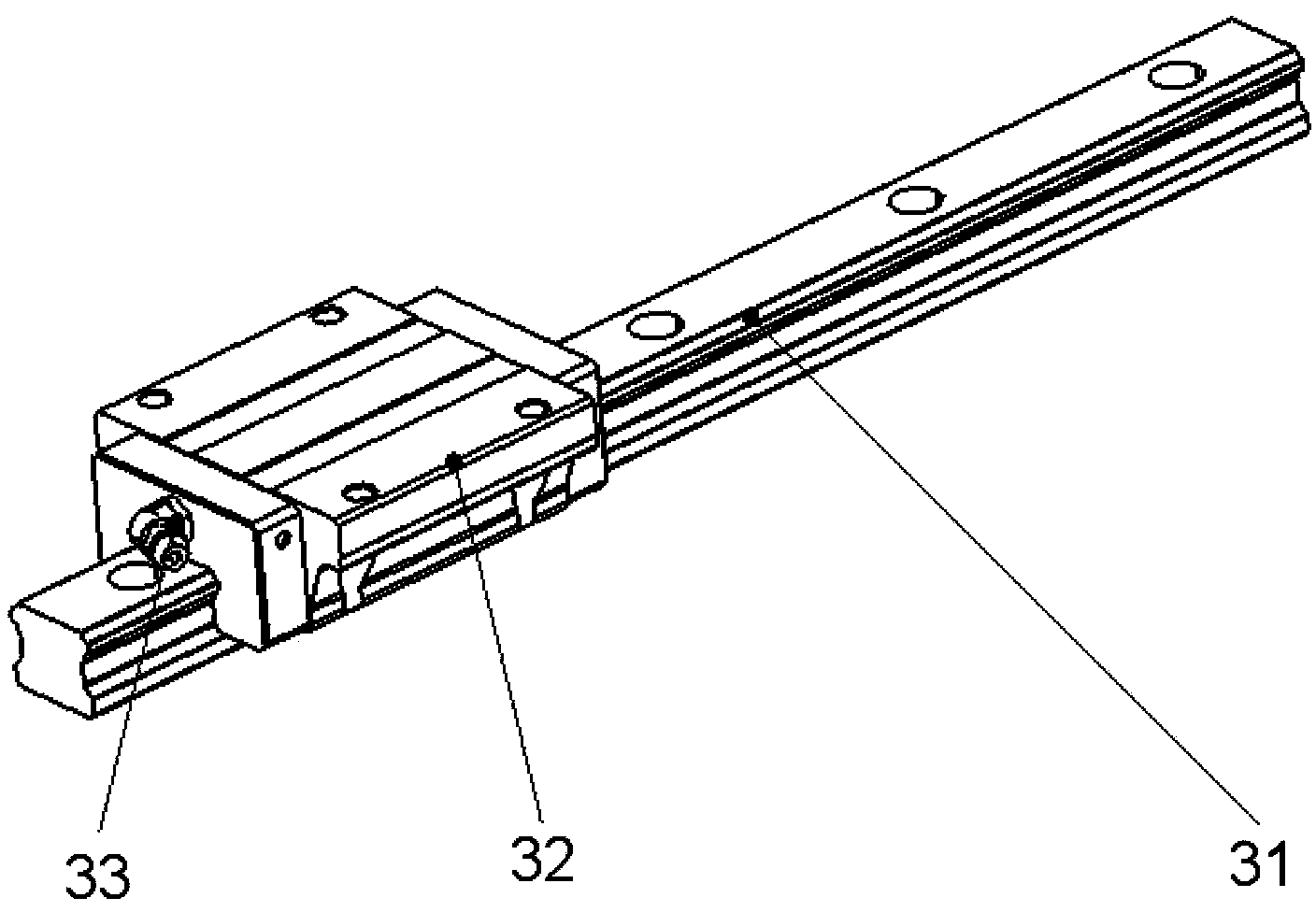

[0016] The concrete structure of guide rail chute assembly 3 is as follows: figure 2 As shown, a double guide rail chute mobile unit is adopted, including two guide rails 31 arranged in parallel and a slider 32 arranged on the guide rail 31. The slider 31 and the guide rail 32 are provided with mutually matching chute, so that the slider 31 can slide along guide rail 32. The cylinder fixing bracket 5 is fixedly connected with two slide blocks 31 located on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap