Tool and method for assembling gear in track traffic gear case

A technology for rail transit and assembling tooling, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of increased assembly time, economic loss, long occupation time, etc., to improve assembly accuracy and stability, and reduce human factors. The effect of affecting and shortening the assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

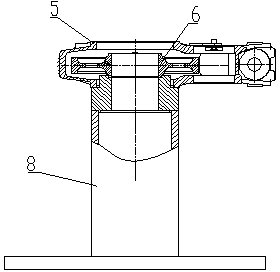

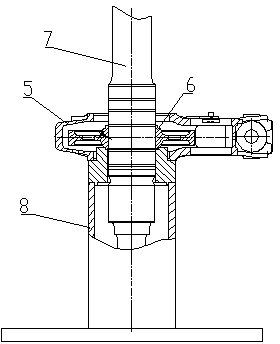

[0036] Such as figure 1 , 2 , 3, 4, and 5, the existing rail transit gear box gear shrink-fit assembly method includes the following steps: gear 6 heating, gear box casing 5 preparations (see figure 1 ), the gear 6 is lightly put into the gearbox case 5 (see figure 2 ), the gearbox case 5 (with gear 6) is turned from vertical to horizontal (see image 3 ), the gearbox case 5 (with gear 6) is placed on the positioning tool 8 (see Figure 4 ), the axle 7 is inserted into the gear 6, oiled and cooled (see Figure 5 ).

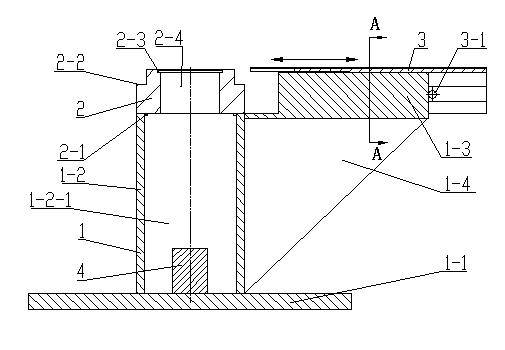

[0037] Such as Figure 6 , 7 As shown, a rail transit gearbox gear assembly tooling of the present invention includes a seat body 1, a positioning base 2 and a sliding seat 3, and the seat body 1 includes a base 1-1, a hollow sleeve 1-2 and a sliding table 1-3, the base 1-1 is located at the lower end of the hollow sleeve 1-2, the slide table 1-3 is located at the upper side of the hollow sleeve 1-2, and the positioning base 2 is installed on the base 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com