Pipe clamp for nuclear power steam generator U-shaped pipe

A steam generator and U-shaped tube technology, applied in packaging, internal fittings, etc., can solve problems such as damage to the U-shaped heat transfer tube, and achieve the effects of convenient production, increased stability, and prevention of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

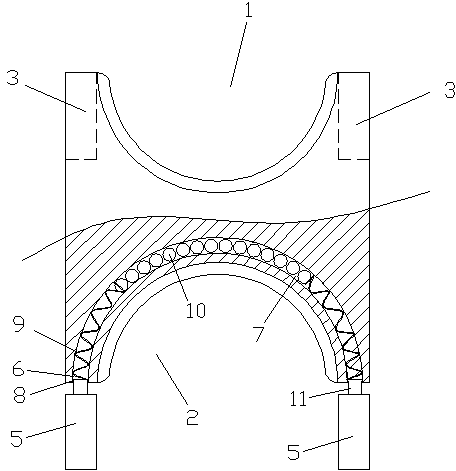

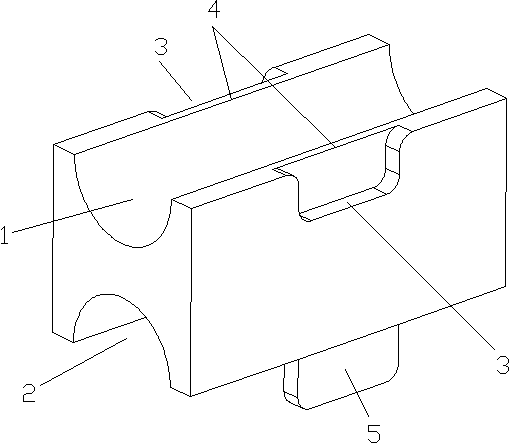

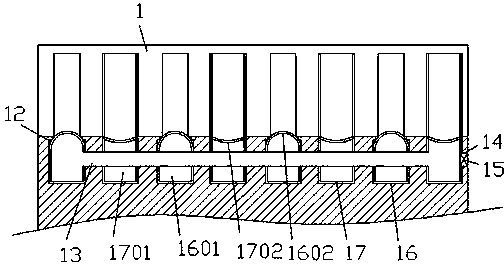

[0024] Examples, see attached figure 1 , 2 , 3, the pipe clip used for the U-shaped pipe of the nuclear power steam generator, the pipe clip is made of nylon 6, chamfered around, it includes the upper arc groove 1, the lower arc groove 2, located on the upper The upper card slot 3 on both sides of the circular arc groove 1, the upper side wall 4 between the upper card slot 3 and the upper circular arc groove 1, and the upper side wall 4 located on both sides of the lower circular arc groove 2 The lower clamping plate 5 has the corresponding position of the upper arc groove and the lower arc groove, and the cross section is arc-shaped, and the upper clamping groove 3 is a rectangular clamping groove, which communicates with the outer surface of the pipe clamp, and the number is two. Located on both sides of the upper arc groove, bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com