Cable-stayed sling type vertical-lifting lifting appliance having large-stiffness frame structure and assembled lifting appliance

A technology of cable-stayed sling type and frame structure, which is applied in the field of spreaders, can solve problems that affect product rigidity, unfavorable product protection, and affect product performance, and achieve the effects of protecting products, reducing stress, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

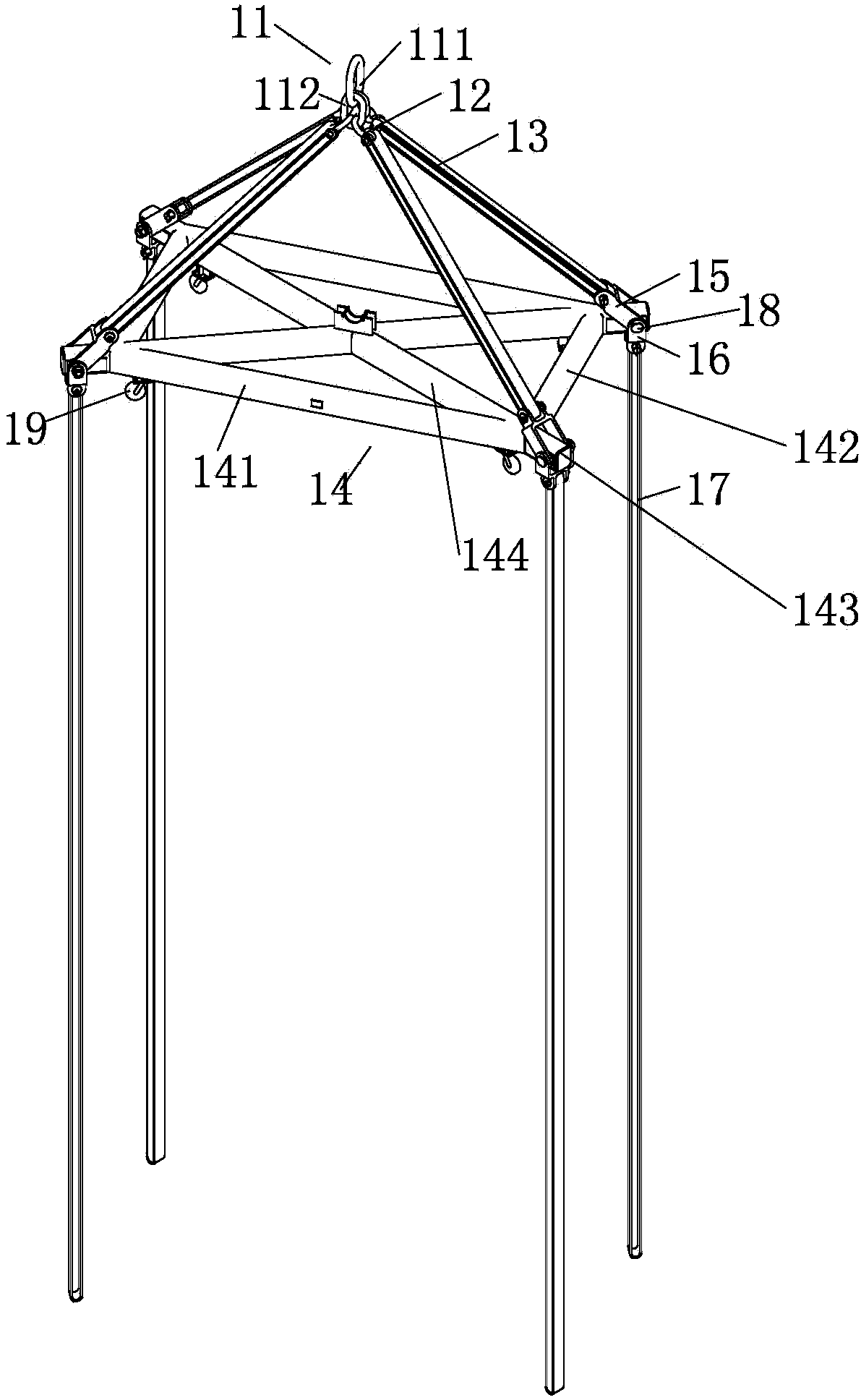

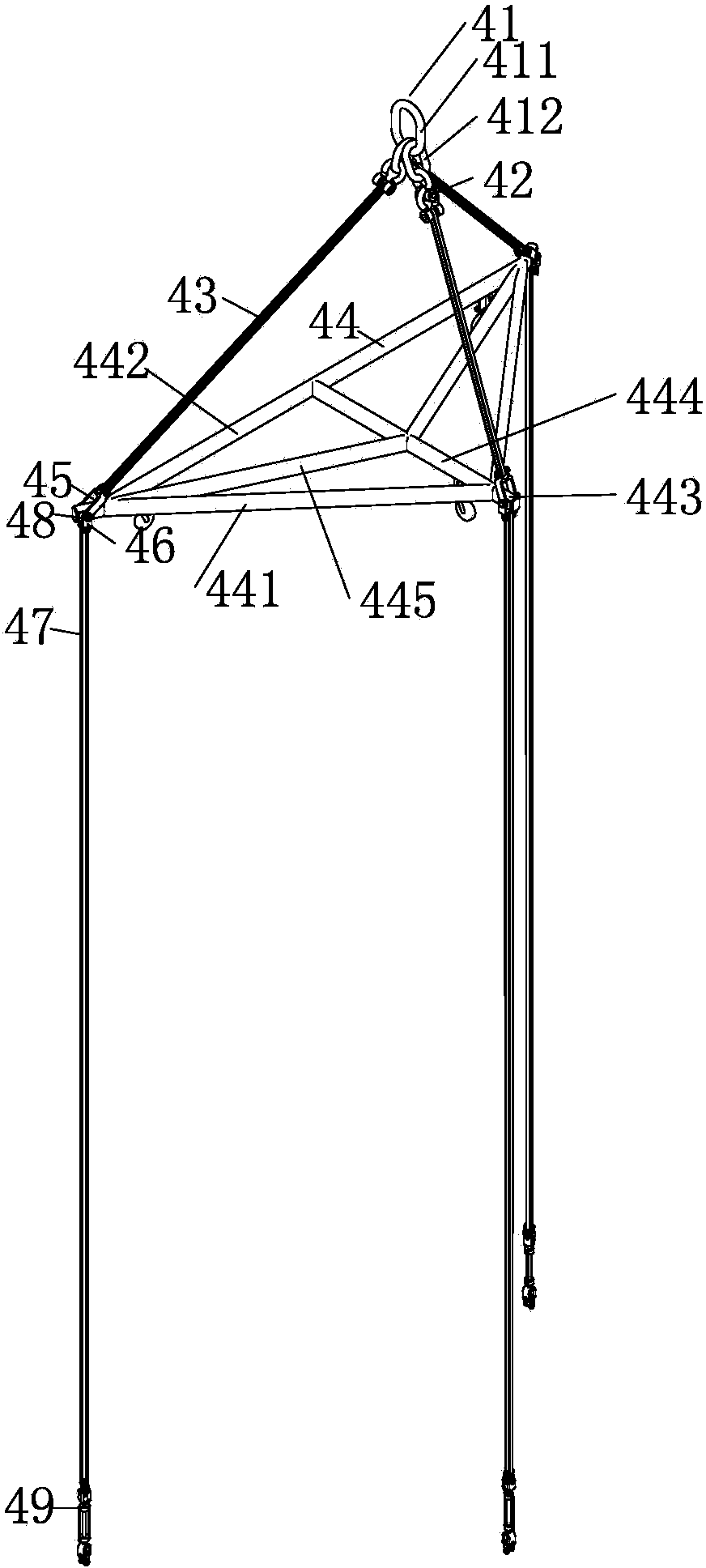

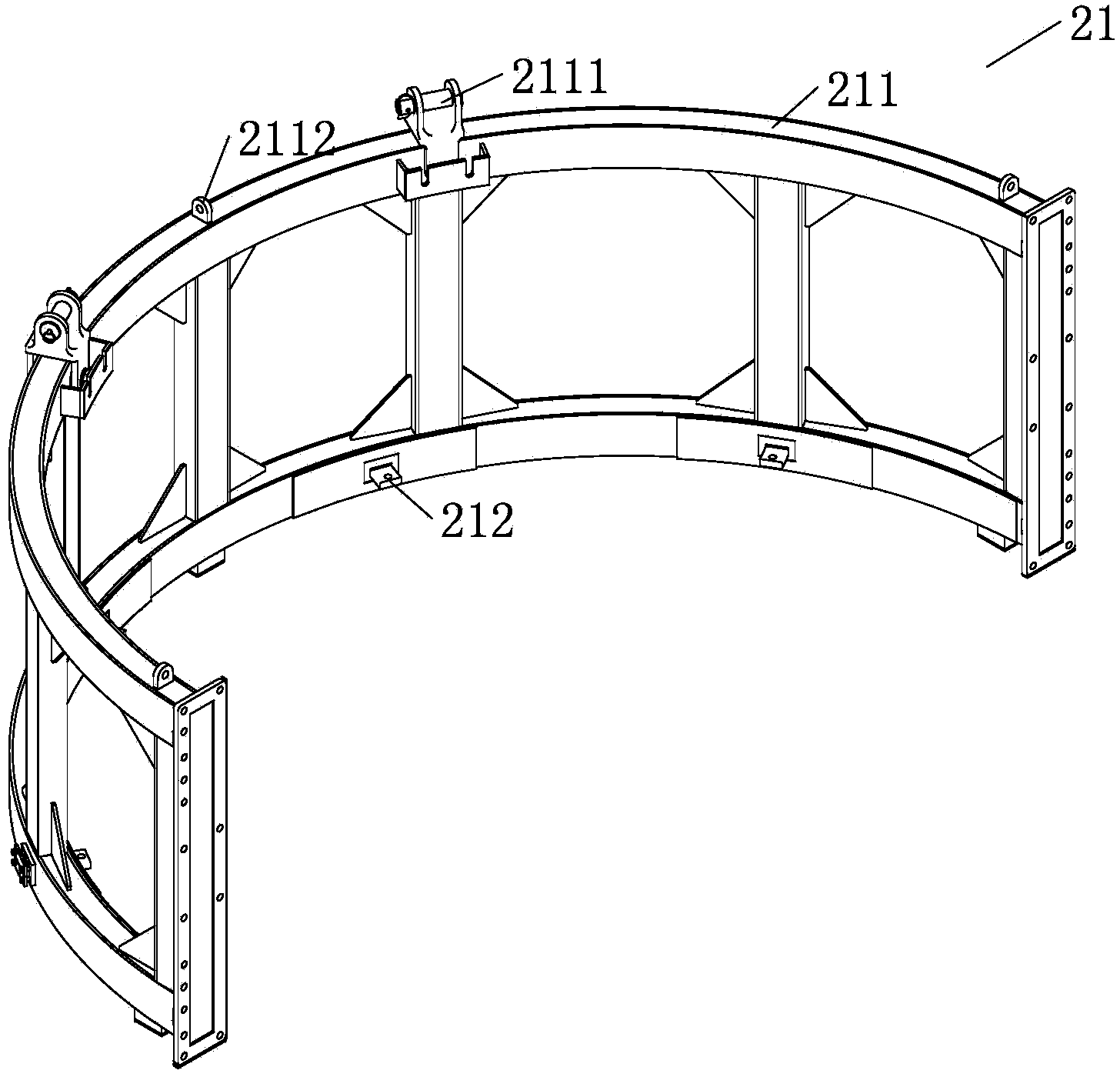

[0024] combine figure 1 , image 3 and Figure 5 As shown, the cable-stayed sling type large rigidity frame structure vertical lifting sling of the present invention comprises an integral sling 1, a hanging basket 2, a limit ring 3, and the integral sling 1 comprises a suspension ring 11, a shackle 12, an upper sling 13, Frame 14, upper connecting fork 15, lower connecting fork 16, lower sling 17 and a plurality of bearing pins 18, frame 14 comprises the 3rd beam 144 that two crosses are fixedly connected, intersection point bisects two 3rd beams 144, two 3rd beams The ends of 144 are used as four lifting points 143 of frame 14, two first beams 141 and two second beams 142 are fixedly connected between the ends of two third beams 144, two first beams 141 are arranged oppositely, two second The beams 142 are oppositely arranged, and the end of each third beam 144 is provided with casters 19 near the lower end of the lifting point 143, so as to facilitate the transfer of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com