Split type flat bottom malt-steeping tank

A split-type malting trough technology, applied in malt preparation, beer brewing, biochemical equipment and methods, etc., can solve the problems of unreliable use, heavy weight, increased noise, etc., and achieve good sealing performance. Ease of use and reliability, the effect of improving smooth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

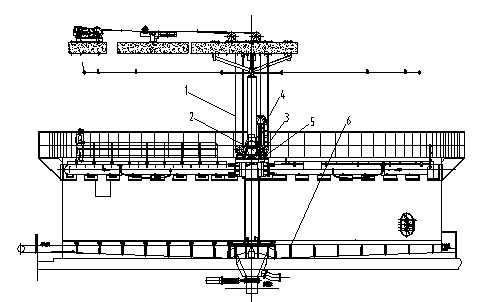

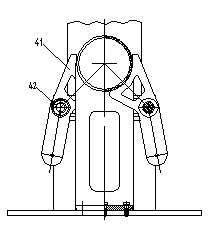

[0022] The present invention includes a leveling machine, the leveling machine is connected with a lifting device that makes the leveling machine move up and down, a sieve plate is arranged at the lower part of the leveling machine, and a plurality of through holes are provided on the sieve plate. The air inlet pipe and the water inlet pipe; the sieve plate is a split structure and is assembled by a plurality of sieve plates.

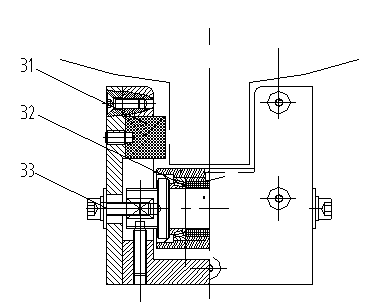

[0023] The lifting device includes a lifting shaft sleeved outside the central pillar, and rail limiters are arranged on both sides of the lifting shaft. The structure of the rail limiter is: a through hole that hugs the lifting shaft is provided in the through hole. The bearing supporting the guide lift shaft and the wear-resistant block contacting the center pillar.

[0024] The housing of the rail limiter is provided with an adjusting bolt extending from the outside into the housing, and the adjusting bolt is connected with the bearing and the wear block....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com