Underground remote control locking device and remote control locking method

A technology of remote control lock and lock body, which is applied in natural gas drilling and petroleum fields, and can solve problems such as cumbersome operation, intermittent pins, and complex downhole working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

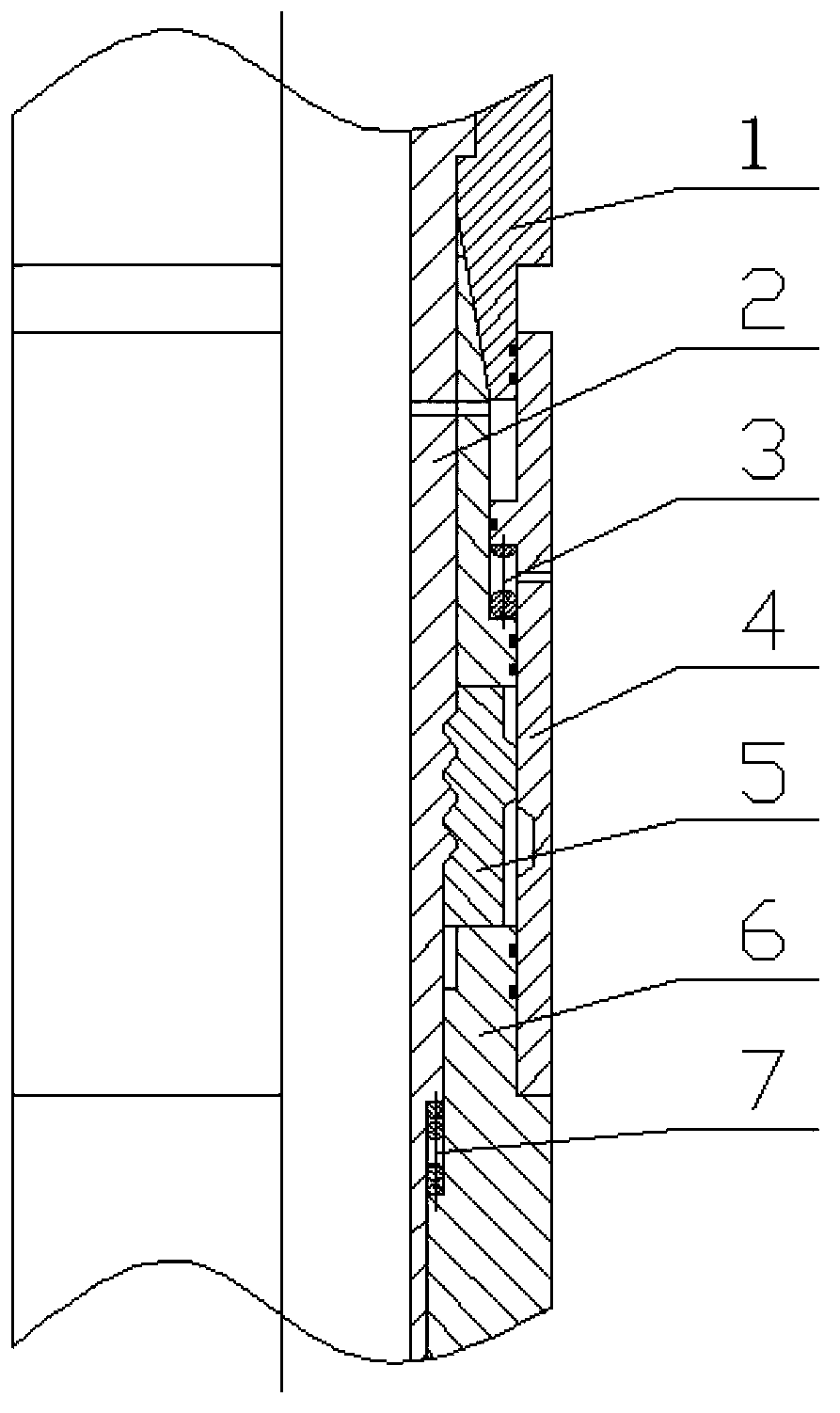

[0016] Embodiment 1: as figure 1 , figure 2 as shown,

[0017] The downhole remote control locking device consists of an upper housing 1, a locked body 2, an unlocking sleeve spring 3, an unlocking sleeve 4, a lock block 5, a body 6, and a locked body spring 7. There are bypass holes on the main body 6, the locked body 2 and the unlocking sleeve 4. The locked body 2 is installed on the inner side of the main body 6, the unlocking sleeve 4 is installed on the outer side of the main body 6, and the main body 6 and the upper casing 1 are connected with threads. The middle part of the body 6 is slotted, and the lock block 5 is installed in the groove of the body 6, and there are at least two slots between the lock block 5 and the body 6 in the circumferential direction. There is a groove in the middle of the locked body 2, and the tooth shape of the axial section meshes with the lock block 5. If the number of axial teeth is large, the axial thrust distributed on each tooth is ...

Embodiment 2

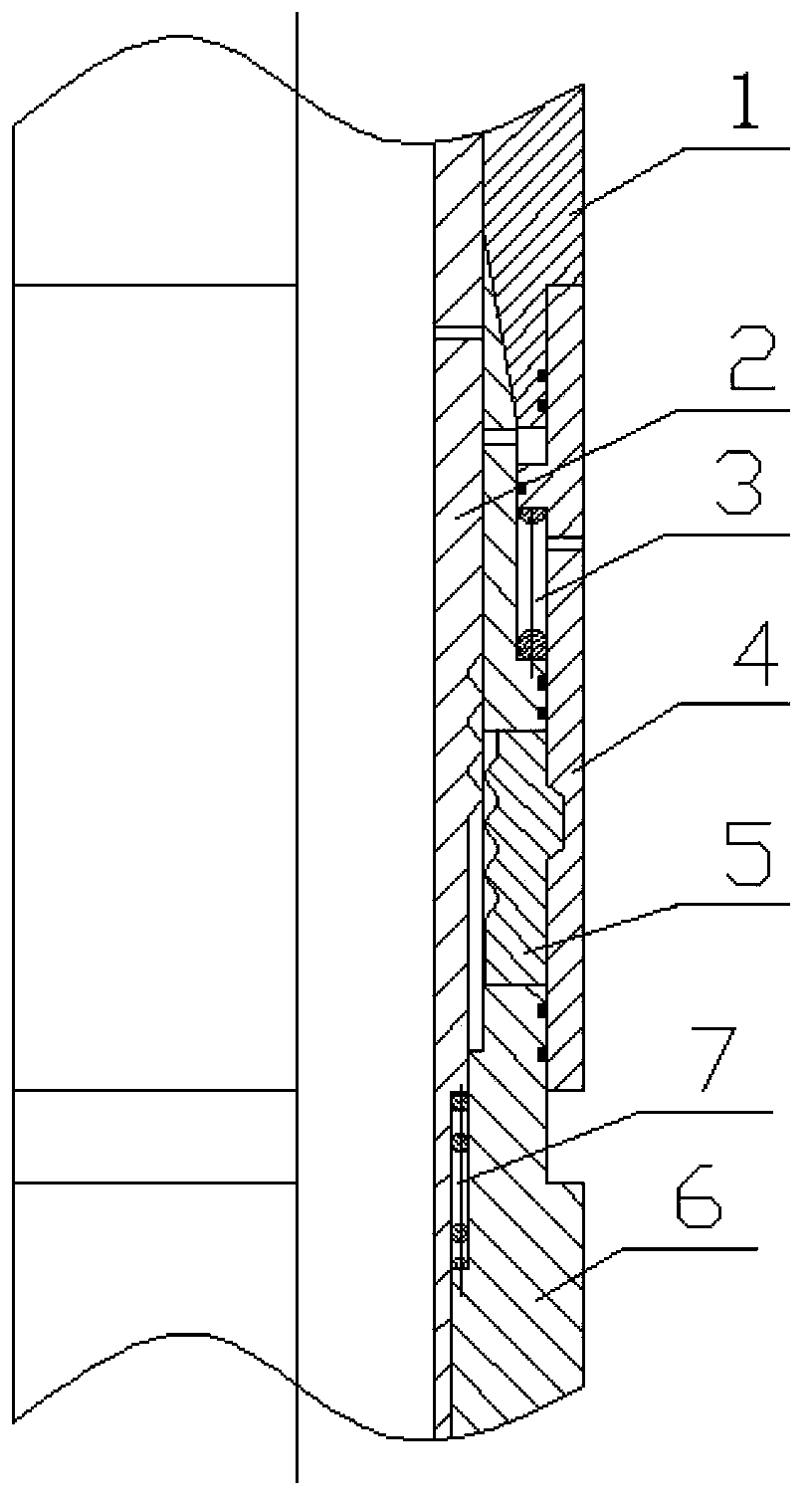

[0021] Embodiment 2: as figure 1 , figure 2 as shown,

[0022] Place the locked body spring and the unlocking sleeve spring on the middle part of the body and the lower step surface respectively, install the lock block in the through hole of the body, install the unlocking sleeve outside the body, connect the upper shell and the body with threads, and finally Put the locked body into the body from top to bottom.

[0023] During normal drilling, the mechanism is in the release state. When locking is required, increase the working displacement to the control displacement. The locked body is aligned with the bypass hole of the body, and the unlocking sleeve moves downward under the action of the pressure difference between the inner and outer rings. , the lock block is engaged with the annular groove of the locked body. At this time, it returns to the normal working displacement, and the mechanism is still in the locked state.

[0024] When release is required, the pump is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com