Dynamic entropy probe

A probe and dynamic technology, applied in the field of dynamic entropy probes, can solve the problems of easy contamination of hot wires, easy breakage, high airflow sensitivity, etc., and achieves low airflow angle sensitivity, reduced difficulty and cost, and high spatial resolution. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

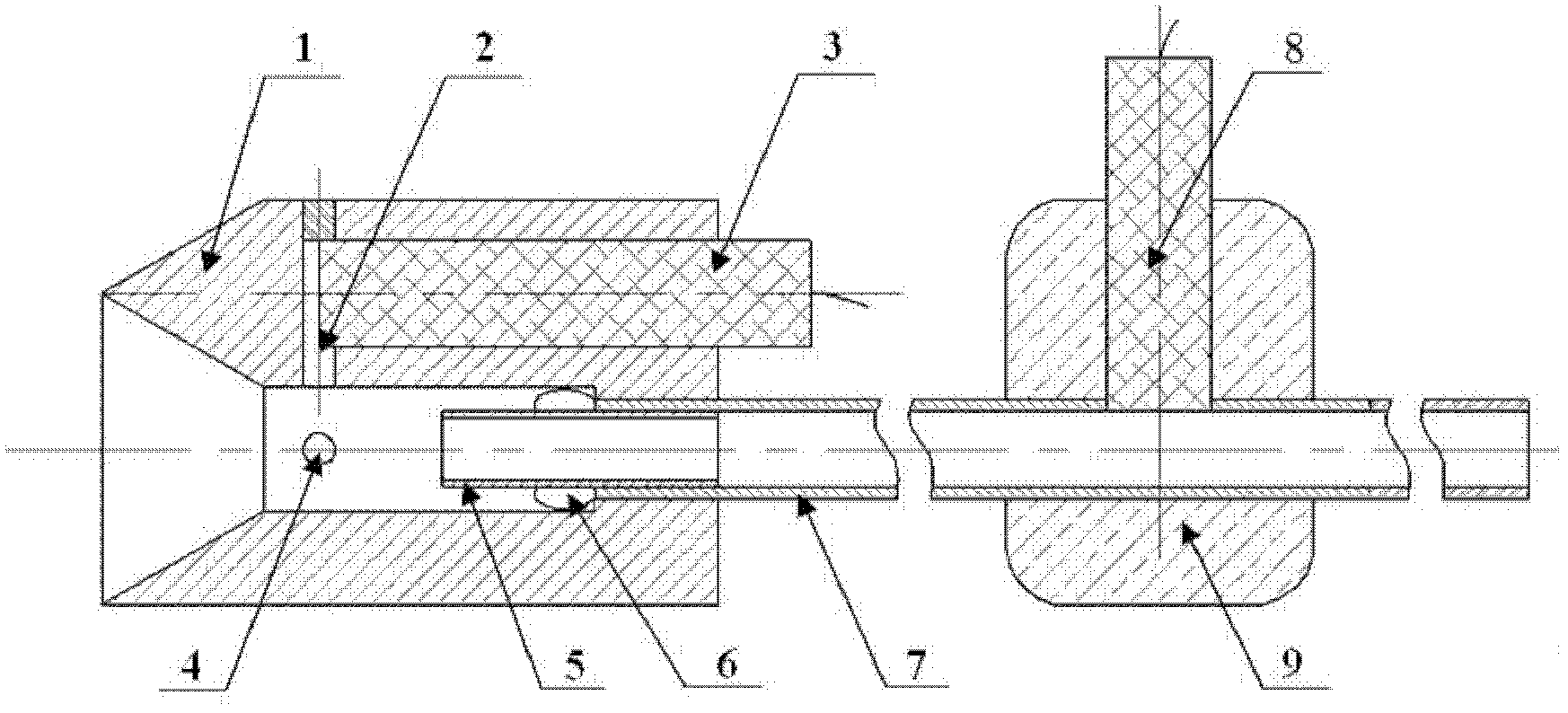

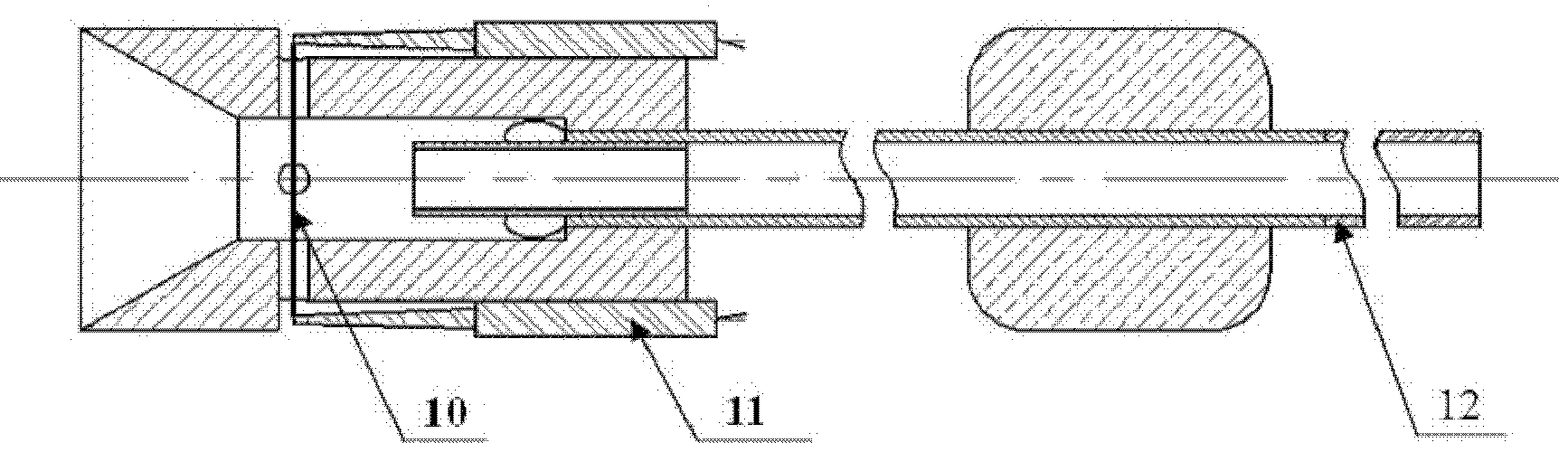

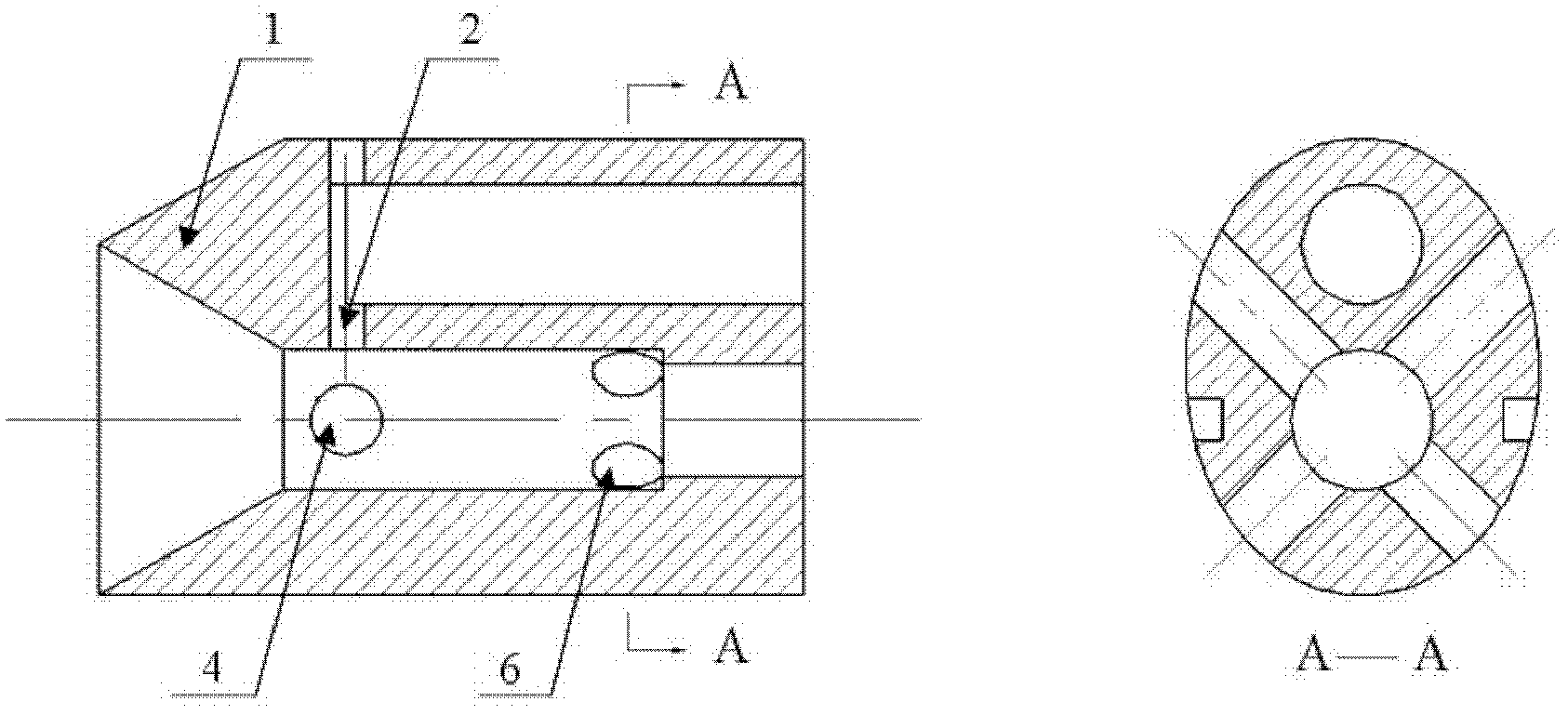

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0040] The principle and design of the entropy probe mainly include: the dynamic total pressure probe technology developed by the applicant's research team, the static pressure hole and two high-frequency response Kulite pressure sensors and the hot-wire anemometer technology, and simultaneously measure the dynamics in the flow field. The total pressure, the static pressure of the flow channel inside the probe and the Ma number can be used to calculate the total temperature and finally the entropy.

[0041] The working principle of the probe is:

[0042] The entrance of the Kiel fairing is chamfered, and four axially symmetrical holes are opened on the rear wall. The Kiel fairing is the main structure of the probe head, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com