Multi-phase grid driver and display panel thereof

A display panel and driver technology, which is applied in the direction of instruments, static memory, static indicators, etc., can solve the problems of increasing the number of wires and increasing the frame width of the display panel, and achieve the effect of reducing the number of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

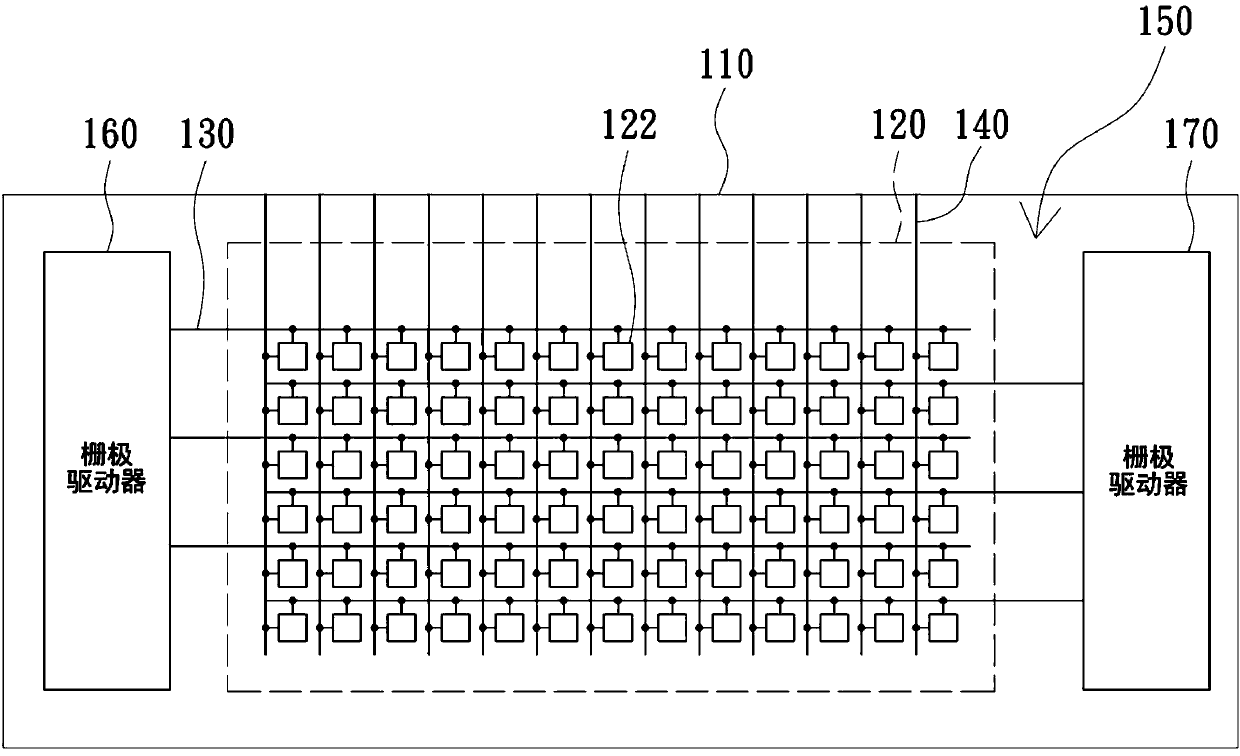

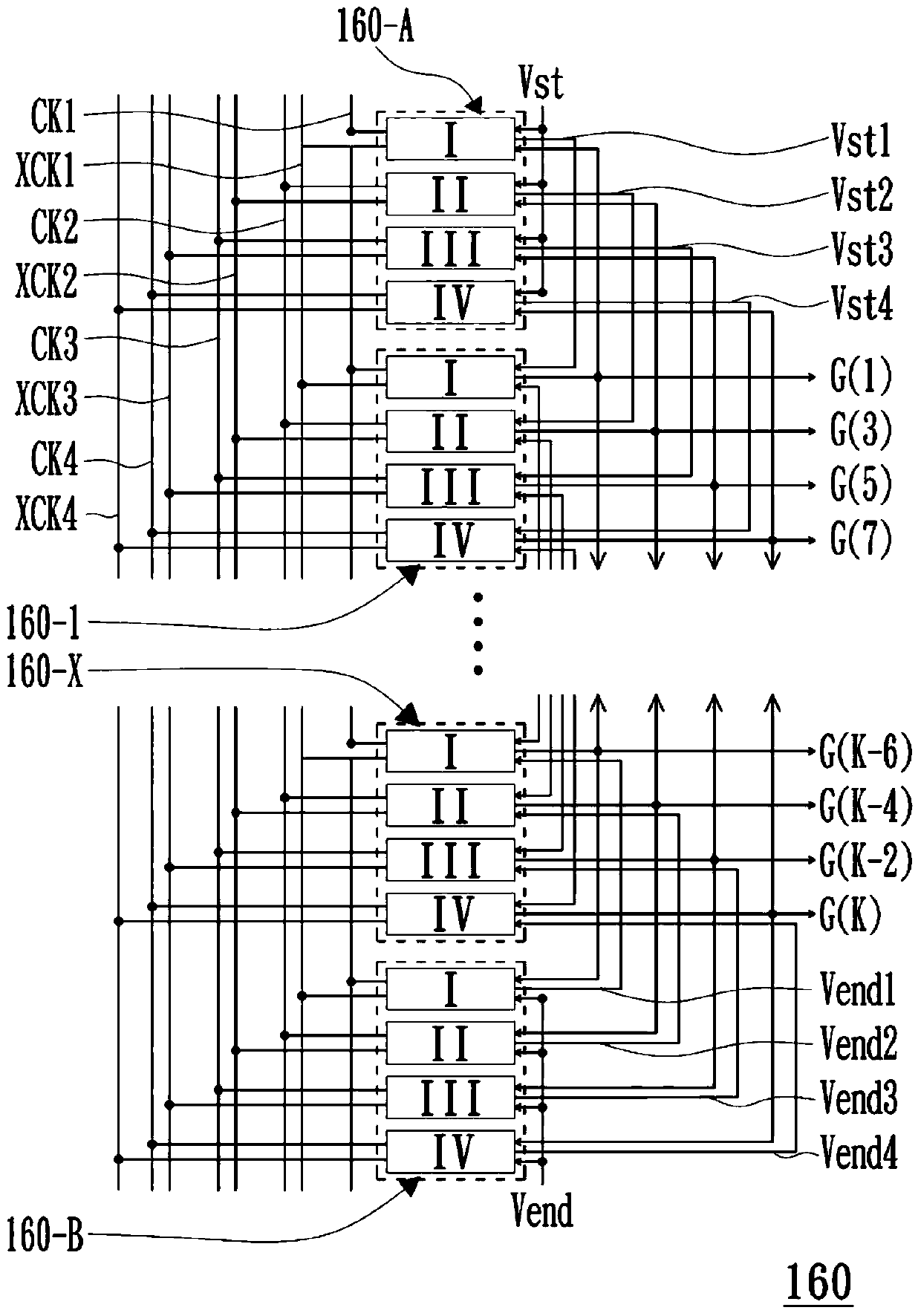

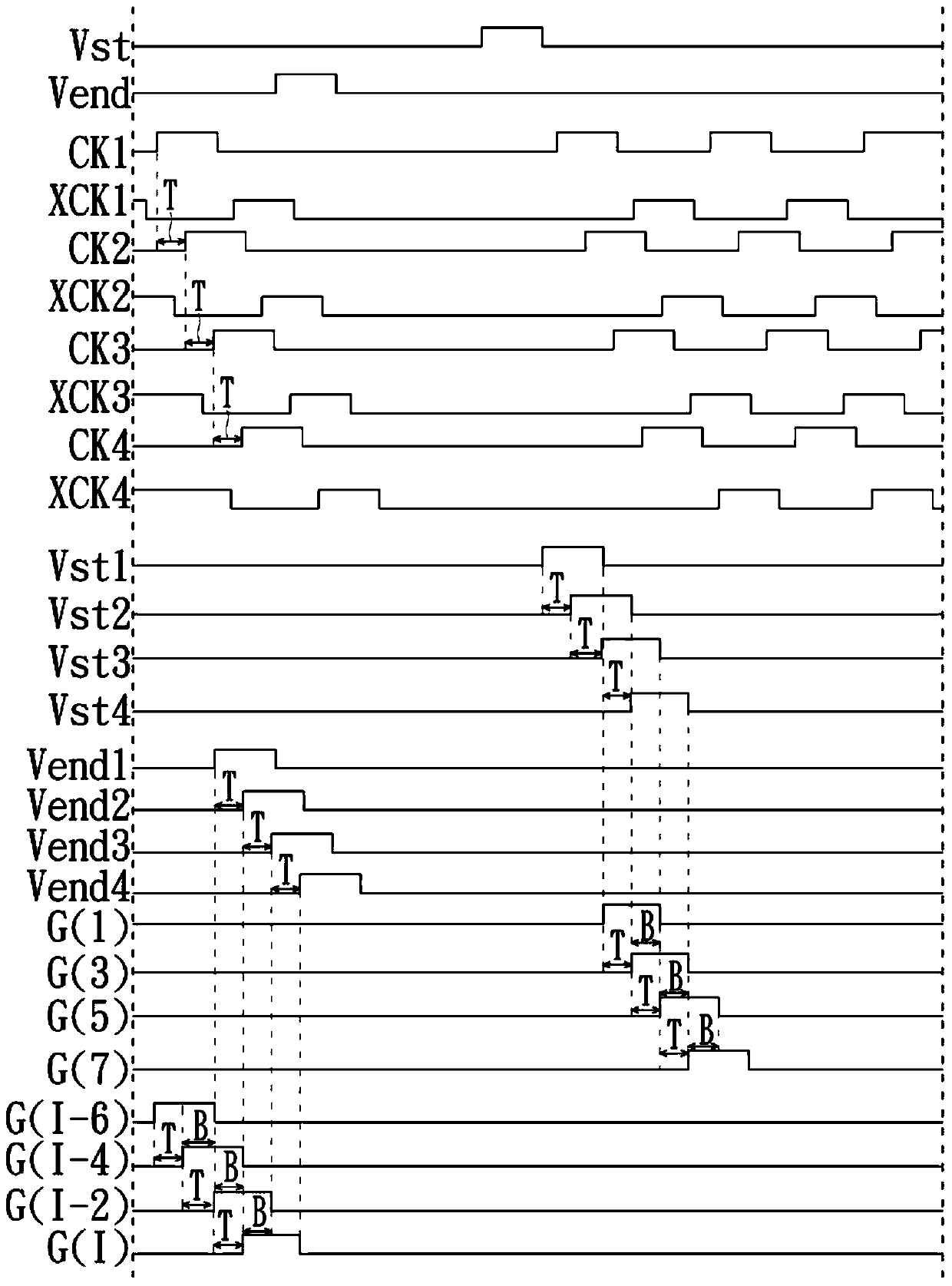

[0030] figure 1 is a schematic diagram of a display panel 100 according to an embodiment of the present invention. Please refer to figure 1 In this example, the multi-phase gate driver 160 and the multi-phase gate driver 170 are produced by using a multi-phase array substrate gate driving technology. exist figure 1 Among them, the substrate 110 includes a pixel matrix 120 composed of a plurality of pixels 122 . Each pixel 122 is electrically coupled to a corresponding gate line 130 and a corresponding source line 140 . And as figure 1 As shown, the multi-phase gate drivers 160 and 170 are directly fabricated in the peripheral area 150 of the display panel 100 formed by the substrate 110 , and are disposed on opposite sides of the display panel 100 . In this embodiment, taking double-sided gate driver driving as an example, the multi-phase gate driver 160 is electrically coupled to the odd-numbered gate lines 130, while the multi-phase gate driver 170 is electrically coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com