Embedded type touch display panel

A touch display panel, embedded technology, applied in optics, instruments, electrical digital data processing and other directions, can solve the problem of limited number of signal transmission lines, large contact impedance, etc., to increase the coupling length, increase the signal-to-noise ratio, Effect of increasing side capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

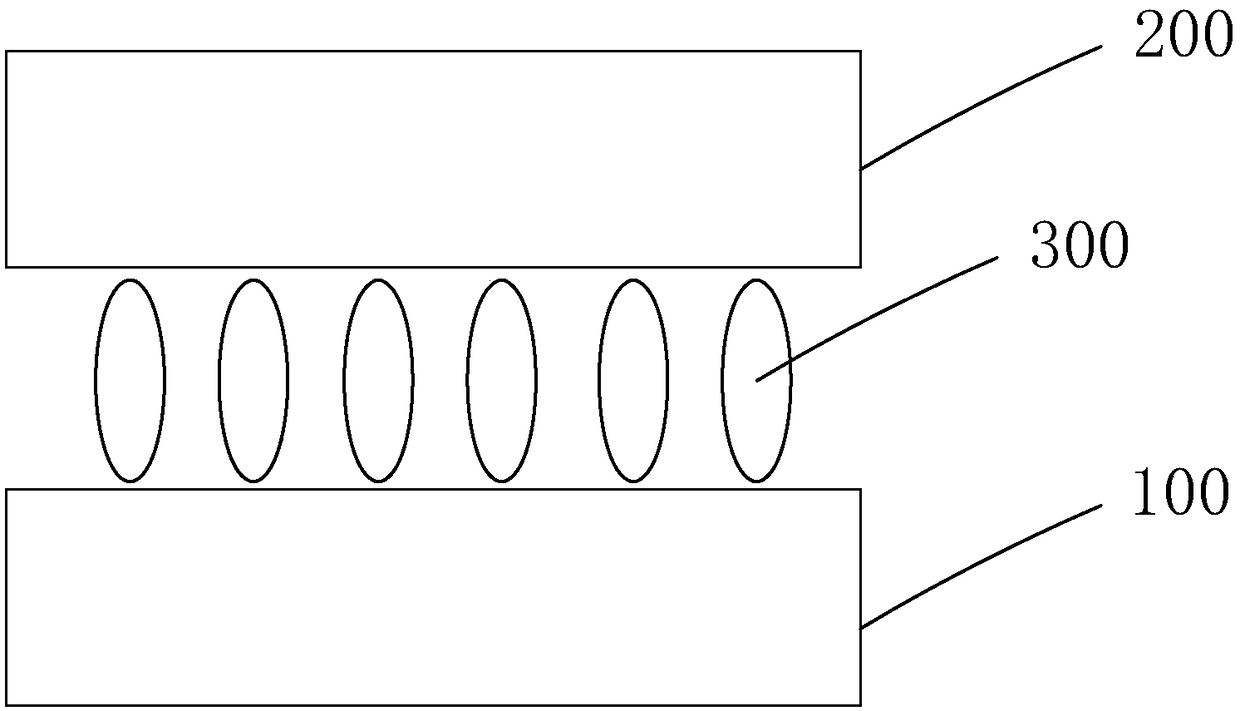

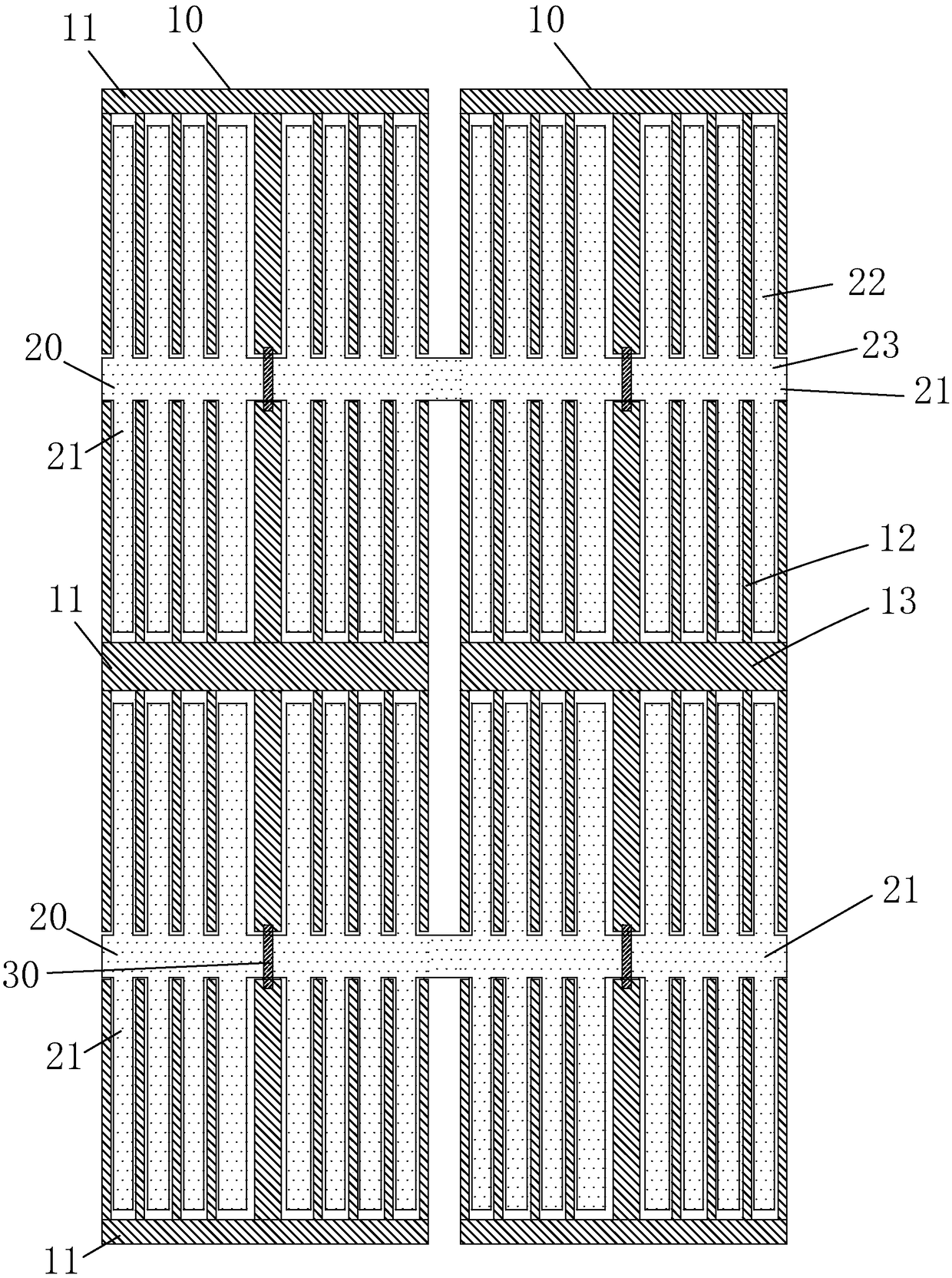

[0032] see Figure 2 to Figure 4 , the present invention provides an in-cell touch display panel, comprising: a TFT substrate 100 and a CF substrate 200 disposed opposite to each other, and a liquid crystal layer 300 disposed between the TFT substrate 100 and the CF substrate 200; the TFT substrate 100 includes: a first base substrate 101, and a first metal layer M1, a second metal layer M2, and a third metal layer M3 that are sequentially formed on the first base substrate 101 and insulated from each other;

[0033] The second metal layer M2 includes a plurality of bridging wires 30;

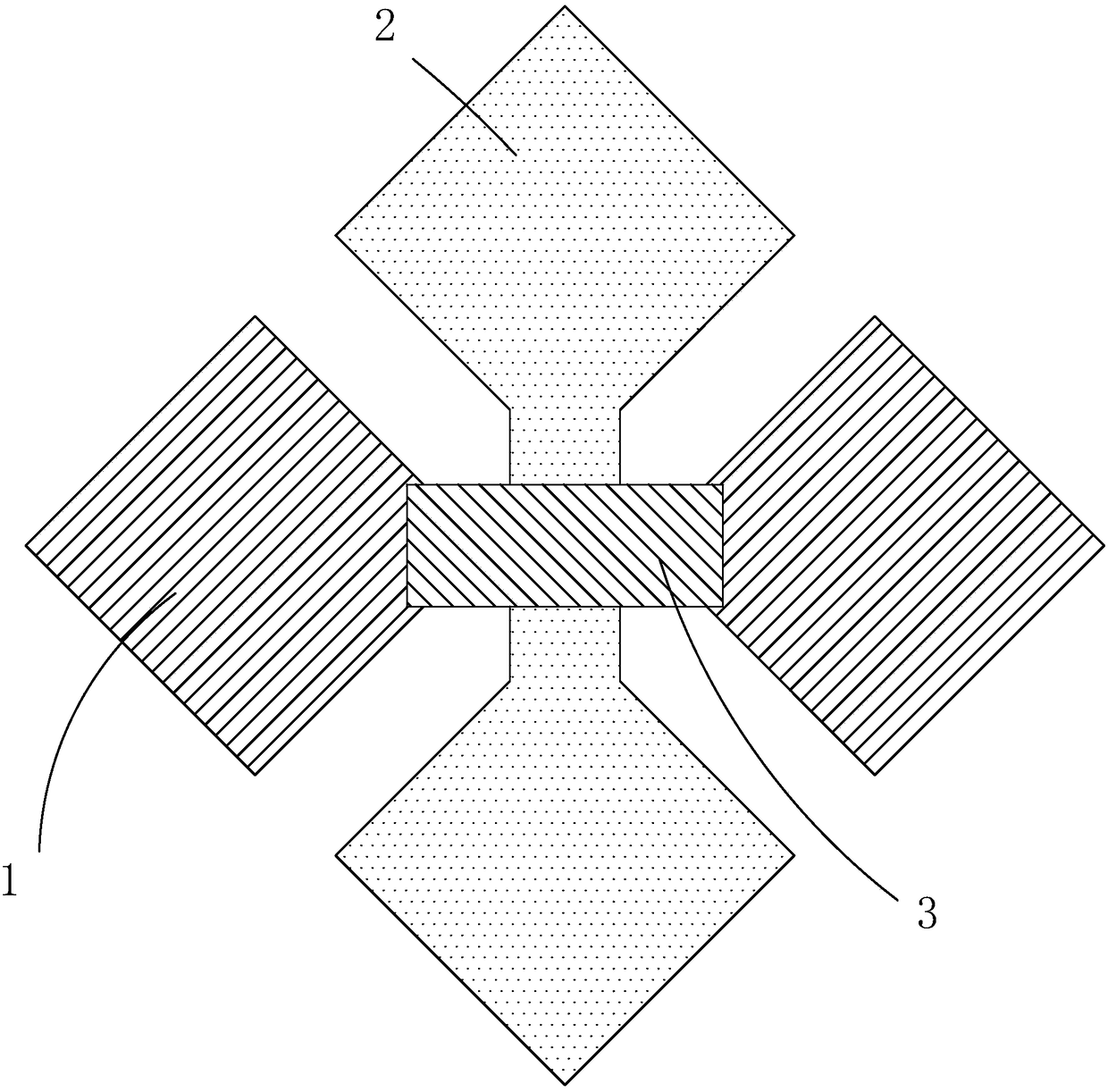

[0034] The third metal layer M3 includes a plurality of driving electrode strings 10 arranged in parallel in the longitudinal direction, and a plurality of se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com