Spent fuel circulating cooling system

A circulating cooling system and circulating cooling technology, applied in the field of spent fuel storage, can solve the problem of high storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

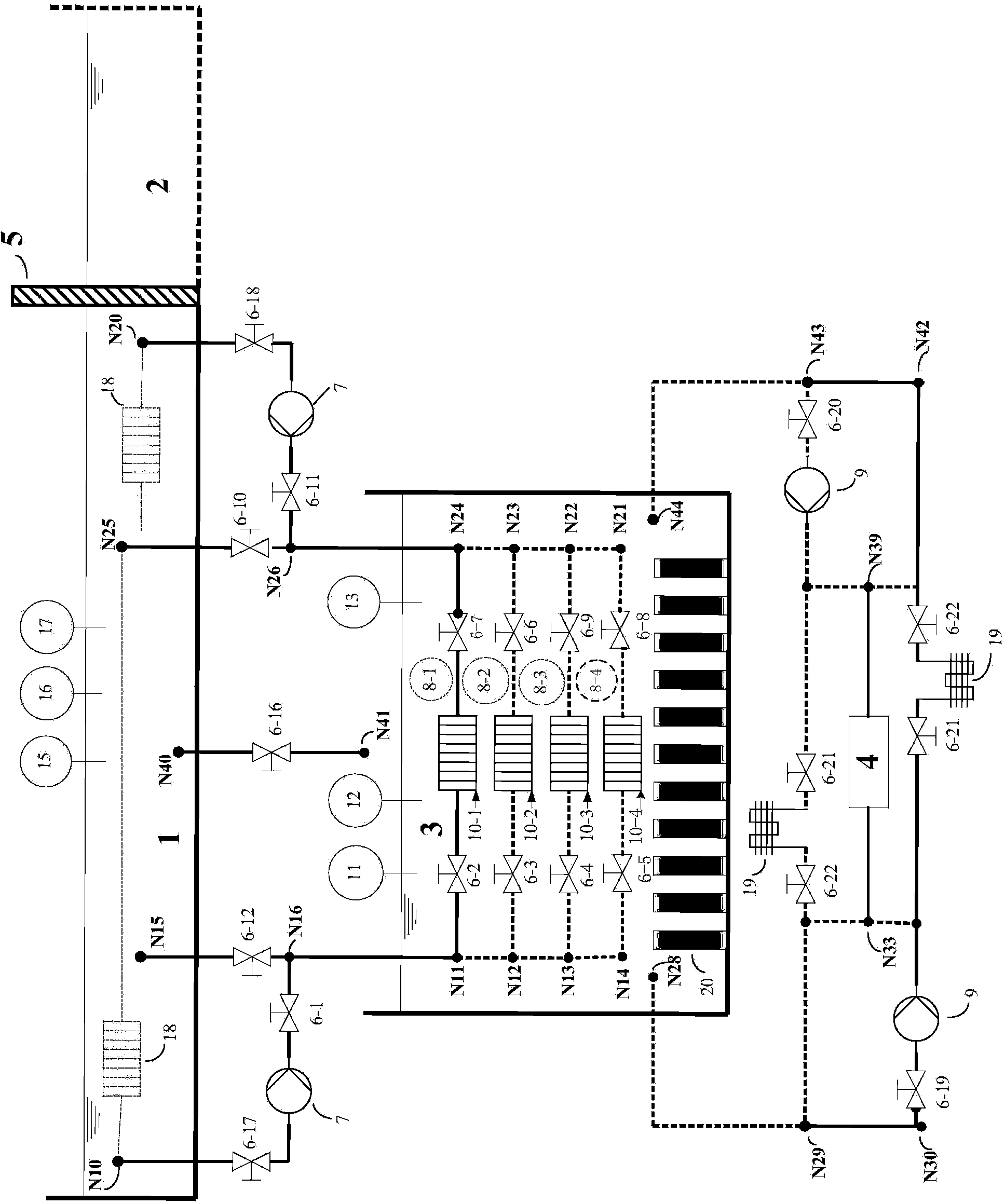

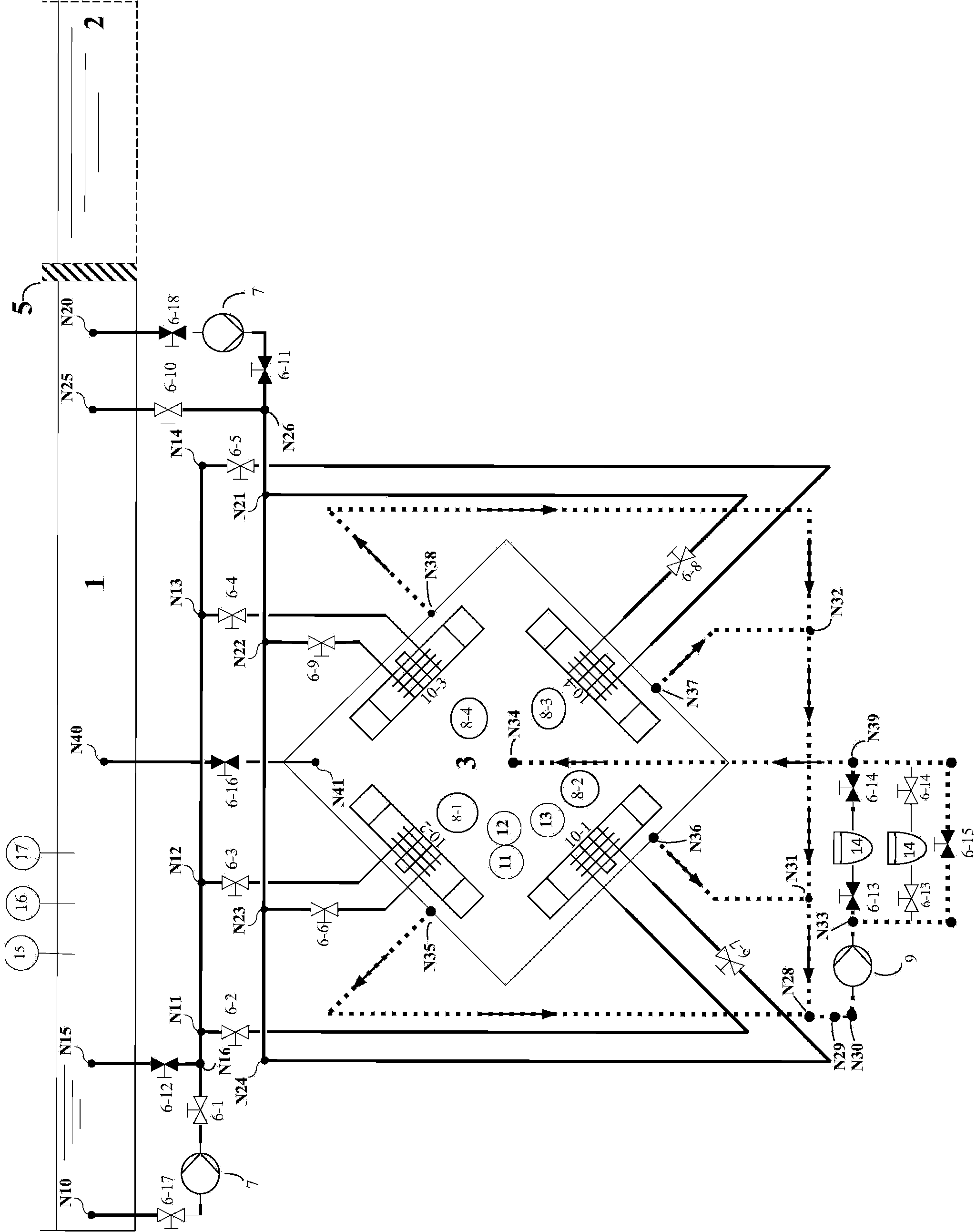

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

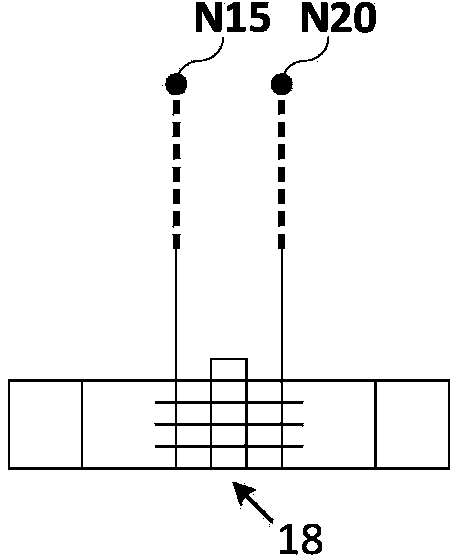

[0022] Such as figure 1 As shown, a spent fuel circulating cooling system provided by the present invention includes a spent fuel storage pool 3, an intermediate heat exchange pool 1 connected to the spent fuel storage pool 3, and a final heat sink 2 containing a cold water body. The hot water pool 1 is separated from the final heat sink 2 by the final heat sink isolation gate 5 arranged between them. Among them, the spent fuel storage pool 3 is used to store the spent fuel assembly 20 and contain the radioactive substances that may be produced; the intermediate heat exchange pool 1 is used as the intermediate heat sink of the system and the gravity replenishment water source of the spent fuel pool; the final heat sink 2 is connected to the intermediate heat exchange pool 1 Perform water body exchange to realize system heat export.

[0023] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com