Fungus bract bag removing machine for factorial production of mushrooms

A factory-like, fungus bud technology, applied in the fields of horticulture, application, and botanical equipment and methods, can solve the problems of unsatisfactory bag removal effect, inability to peel off the bacteria bag, low bag removal efficiency, etc., and achieve high bag removal efficiency. , The effect of taking off the bag is good and the degree of automation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

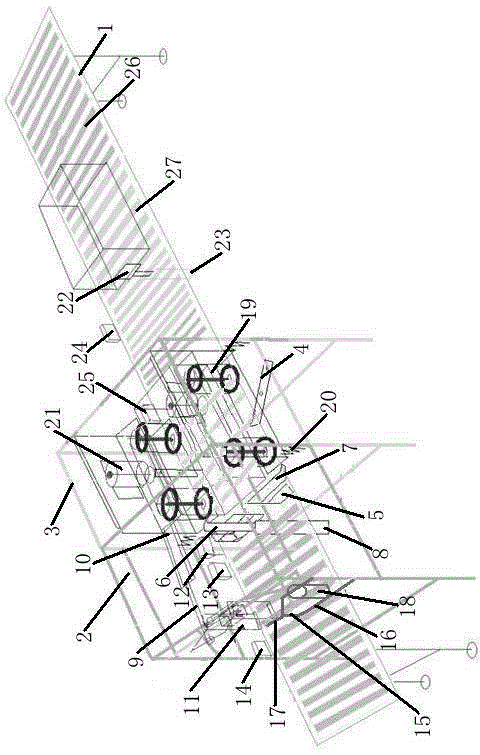

[0019] see figure 1 , a kind of bag-removing machine for buds of shiitake mushrooms in industrialized production, comprising a feeding track 1, a uniform speed drum area 26 and a fast drum area 27 are arranged on the feeding track 1, and a bag-removing mechanism for mushroom buds is installed on the feeding track 1 2. The bud bag removal mechanism 2 includes a frame 3, a spring cutter 4, a smooth and fast cutter 5 and a vertical and vertical fast cutter 6, and the spring cutter 4, the smooth and fast cutter 5 and the vertical and fast cutter Knife 6 is arranged in sequence along the direction that feeding track 1 advances, and described smooth and fast cutter 5 is arranged on the bottom of smooth cutter cylinder 7, and vertical slide fast cutter 6 is arranged on the top of vertical slide cutter cylinder 8, and described machine The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com