A pipe bending device

The technology of a pipe bending device and pipe bending wheel, which is applied in the field of pipe bending, can solve the problems of high cost, easy deformation of heated and bent steel pipes, complex structure, etc., and achieve the effects of preventing harmful deformation, high pipe bending efficiency, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

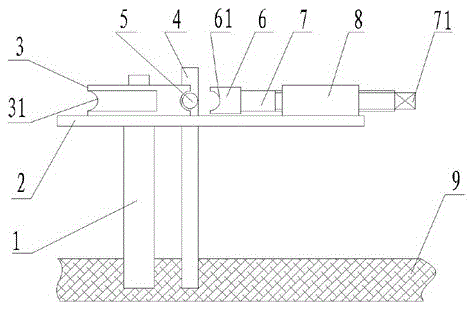

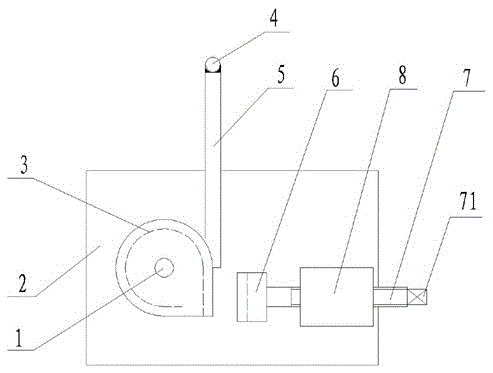

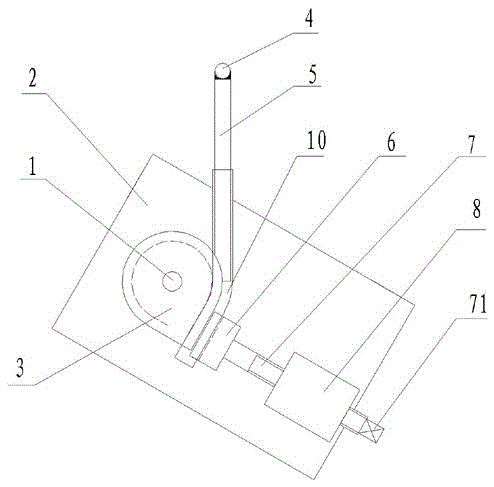

[0012] exist figure 1 , figure 2 Among them, a pipe bending device, which includes a working platform 2 and a platform column 1, one end of the platform column 1 rotates to support the working platform 2, that is, the working platform 2 can rotate around the platform column 1; One end is fixed on the anchor piece 9, and the anchor piece 9 can be a fixed platform, or other parts that keep the position unchanged from the ground. What this embodiment adopts is a fixed platform.

[0013] Such as figure 1 , figure 2 As shown, a pipe bending wheel 3 is set on the platform column 1 , and the pipe bending wheel 3 is fixedly connected to the working platform 1 and rotates synchronously with the working platform 1 . exist figure 1 Among them, a semicircular groove 31 is formed on the circumferential surface of the elbow wheel 3 .

[0014] exist figure 1 , figure 2 Among them, a clamping mold base 6 is provided on one side of the pipe bending wheel 3 . Such as figure 1 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com