An automatic loading and unloading device and loading and unloading method for a lead-acid battery casting welding fixture

A technology of lead-acid batteries and casting and welding fixtures, which is applied in the field of battery casting and welding, can solve problems such as high cost and complex structure of technical solutions, and achieve the effect of low cost, simple and practical loading and unloading methods, and efficient docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

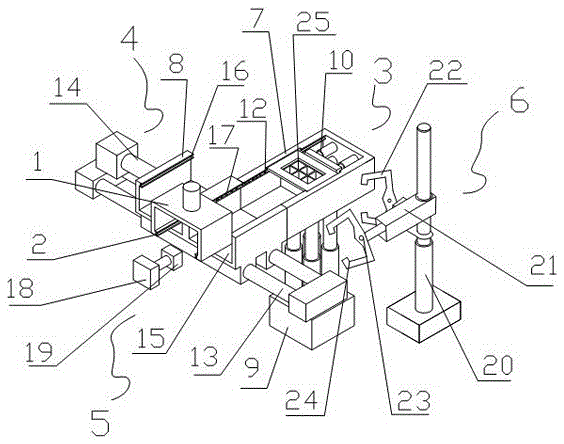

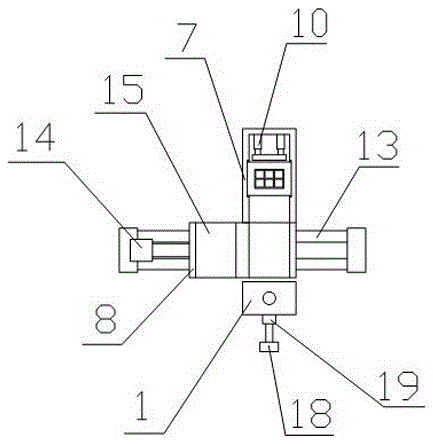

[0034] exist figure 1 In the shown embodiment, an automatic loading and unloading device of a lead-acid battery casting and welding fixture, the automatic loading and unloading device is set corresponding to the casting and welding machine tooling fixture 1 provided with the fixture chute 2, and is connected with the power supply device and the gas source device respectively It is connected with the control system, and the control system is set independently from the control system of the casting welding machine, including the casting and welding fixture conveying device 3, the fixture docking device 4, the fixture retreating device 5 and the grabbing device 6, the casting and welding fixture conveying device 3, and the casting and welding machine tooling Fixture 1 and fixture abdication device 5 are arranged along the same axis (see figure 2 ), the fixture docking device 4 is vertically arranged between the casting fixture 1 and the casting fixture conveying device 3 horizon...

Embodiment 2

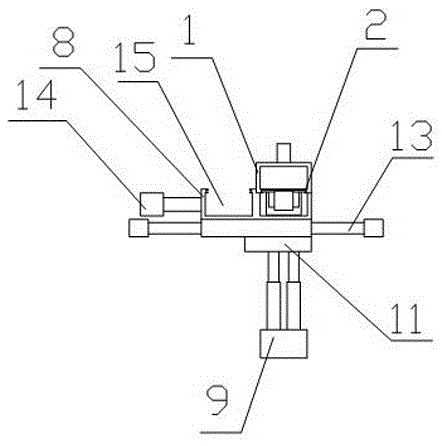

[0042] exist Figure 5 In the shown embodiment, an automatic loading and unloading device of a lead-acid battery casting and welding fixture, the automatic loading and unloading device is set corresponding to the casting and welding machine tooling fixture 1 provided with the fixture chute 2, and is connected with the power supply device and the gas source device respectively It is connected with the control system, and the control system is integrated with the control system of the casting welding machine, including the casting and welding fixture conveying device 3, the fixture docking device 4, the fixture retreating device 5 and the grabbing device 6, the casting and welding fixture conveying device 3, and the casting and welding machine tooling The fixture 1 and the fixture abdication device 5 are arranged along the same axis, and the fixture docking device 4 is vertically arranged between the casting and welding fixture conveying device 3 and horizontally arranged between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com