Clamping device for rear crossbeam of rear sub-frame

A technology of clamping device and rear subframe, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Welding position accuracy, resistance to welding deformation, reducing the effect of space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

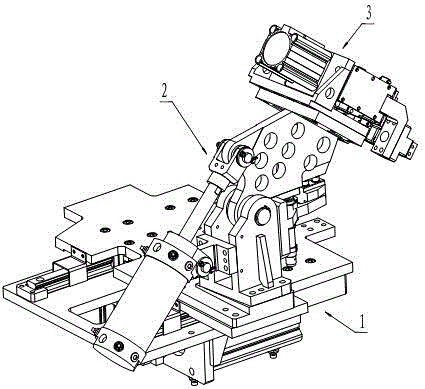

[0026] see figure 1 , The clamping device of the present invention is composed of a slide mechanism 1 , an indexing mechanism 2 and a clamping mechanism 3 . The sliding table mechanism 1 is the basic mechanism of the device, and the sliding table mechanism drives the indexing mechanism and the clamping mechanism to do linear motion, close to the rear sub-frame rear beam workpiece on the base or away from the workpiece. The indexing mechanism 2 is used to drive the clamping mechanism to swing into or out of the inner and outer plates of the rear crossbeam of the rear sub-frame. The clamping mechanism is used for clamping or loosening the inner and outer plates of the rear crossbeam workpiece of the rear subframe.

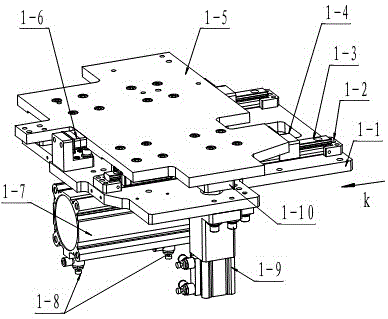

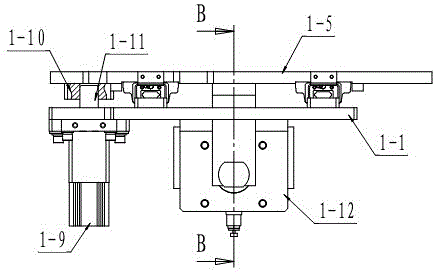

[0027] see figure 2 , image 3 , Figure 4 , the sliding table mechanism includes a sliding table mounting plate 1-1 and a sliding table 1-5, and the sliding table mounting plate fixes the sliding table cylinder 1-7. The sliding table cylinder 1-7 arranged hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com