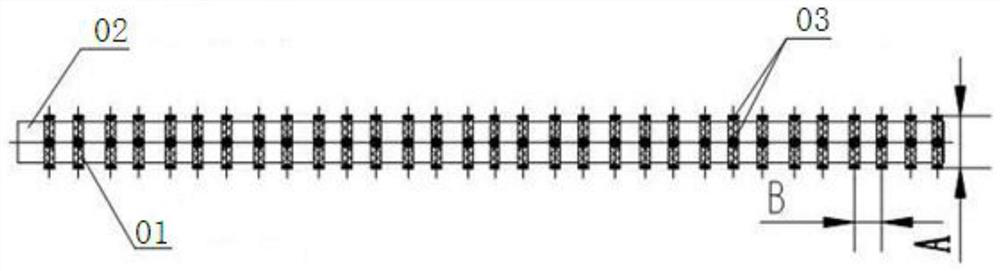

A centipede-shaped connecting piece welding machine

A welding machine and connecting piece technology, used in capacitors, capacitor manufacturing, electrical components, etc., can solve the problems of difficult to guarantee welding quality, high labor cost, low welding efficiency, etc., to meet the requirements of automatic welding, reduce labor costs, and welding efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

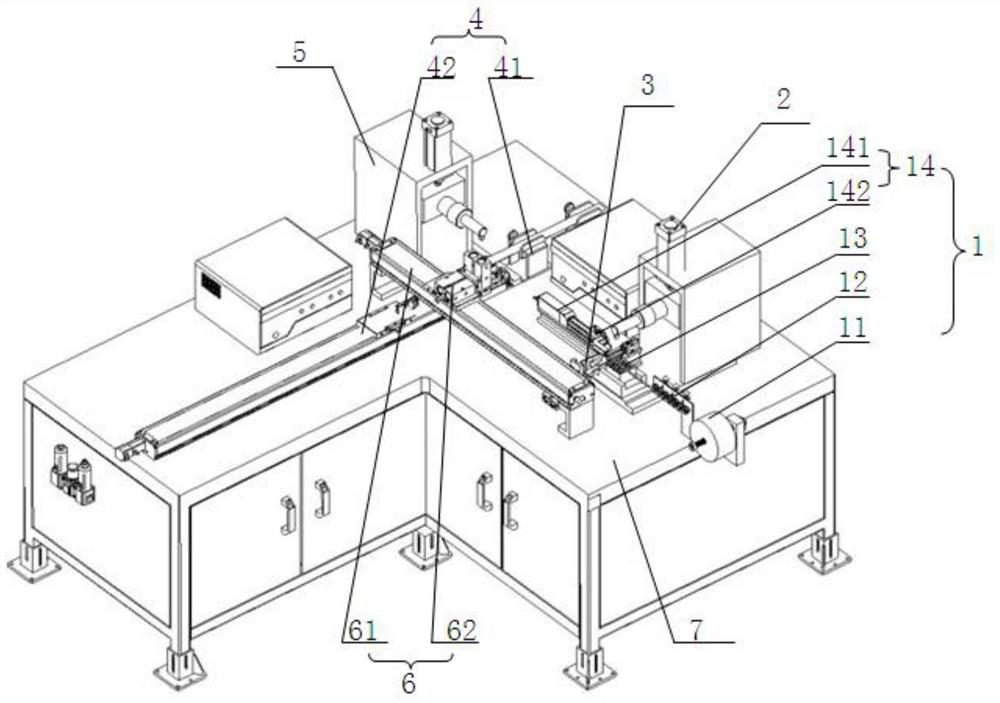

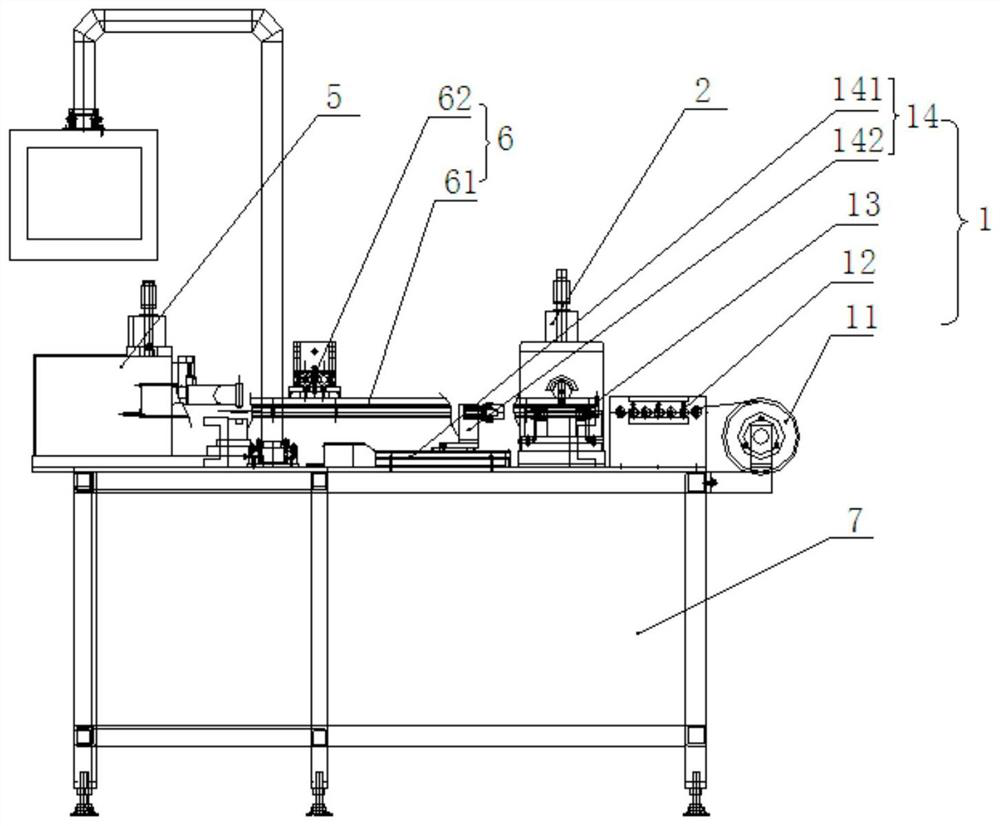

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0069] see Figure 2 to Figure 5 , a centipede-shaped connecting piece welding machine of the present invention, its structure comprises braided wire feeding mechanism 1, the first welding machine 2, cutting mechanism 3, copper belt feeding mechanism 4, the second welding machine 5 and braided wire transfer Institution 6. In the present invention, both the first welding machine 2 and the second welding machine 5 are ultrasonic welding machines, and in addition to the ultrasonic welding machines, they may also be resistance welding machines.

[0070] The braiding wire feeding mechanism 1 includes a wire wheel 11 , a braiding wire leveling mechanism 12 , two braiding wire positioning and clamping mechanisms 13 and a braiding wire conveying mechanism 14 arranged in sequence along the left and right directions. In this embodiment, the braiding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com