A pre-action tempered glass breaker

A technology of tempered glass and glass breaker, applied in the field of emergency escape, to achieve the effect of low production cost, convenient operation, compact and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

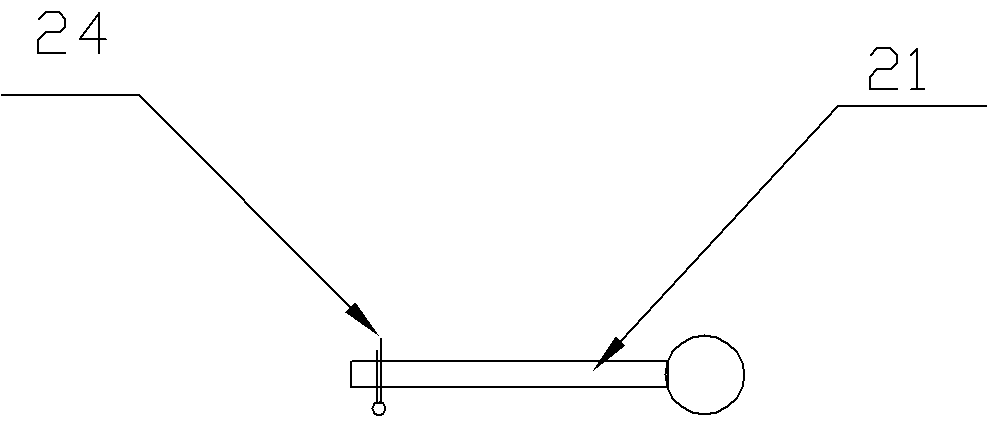

[0018] A pre-action tempered glass breaker, characterized by a trip knob (1), a glass breaker housing (2), an impact spring (3), a glass breaker base (4), and an impact spring seat (6) , impact head (7), connecting rod (8), release spring (17), positioning guide pin (9), glass breaker bolt lock pin (21), plastic safety pin (24), set screw (15) and Screws (5) form.

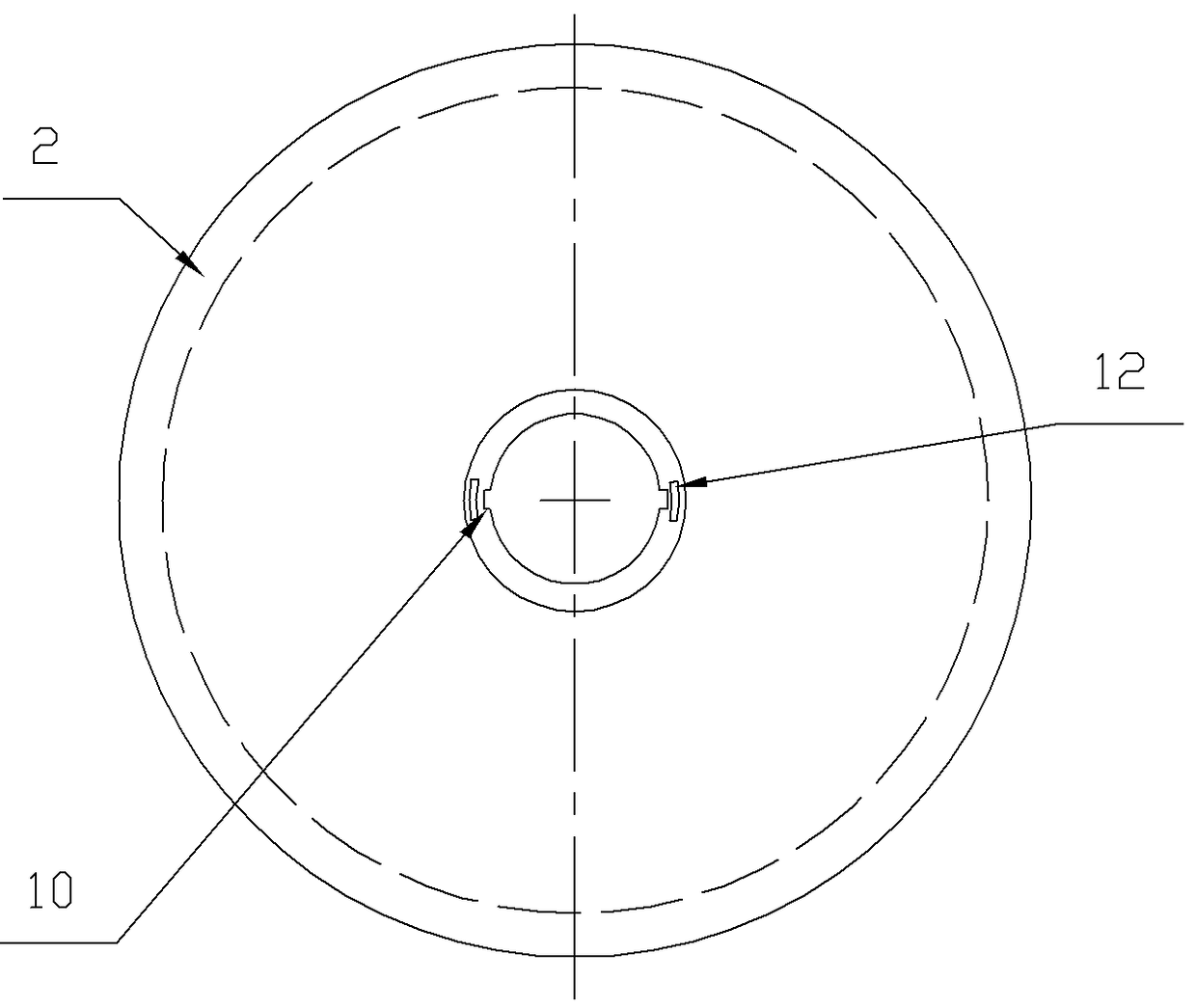

[0019] A pre-action tempered glass breaker is designed as a circular structure, and the glass breaker shell (2) is processed with a glass breaker shell guide groove (10) and a glass breaker shell latch at 180 degrees symmetrically. Pin hole (19), glass breaker housing release spring seat (12) and positioning groove (14).

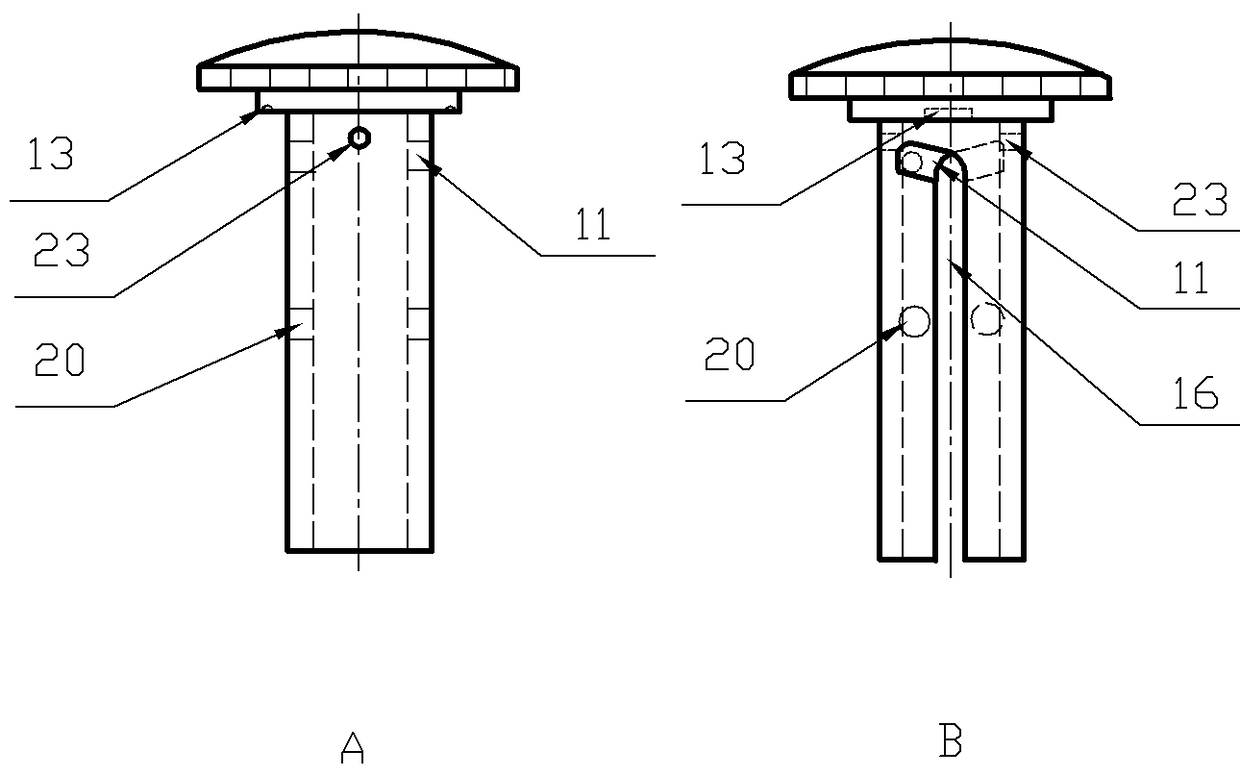

[0020] The trip knob (1) is symmetrically processed with positioning screw holes (23), longitudinal guide grooves (16), trip knob chute (11), trip knob trip spring seat (13) ).

[0021] A positioning screw hole (23) is processed on the tripping knob (1) for installing a positioning screw (15),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com