Hydraulic supporting leg structure and movable type crusher

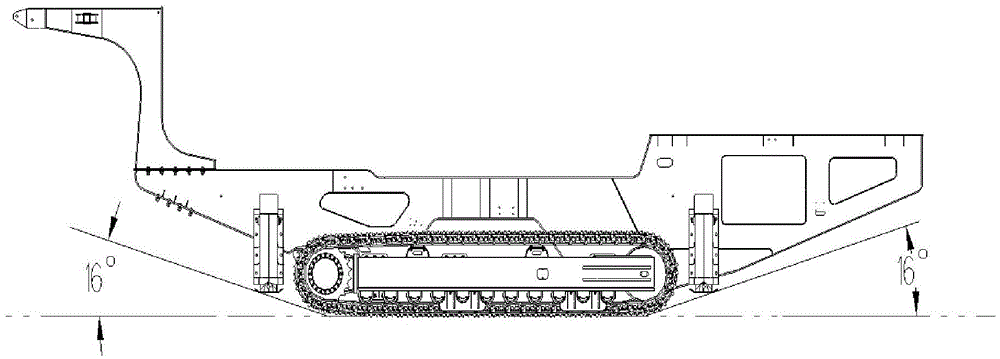

A technology of hydraulic outriggers and crushers, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problem of small progress angle and departure angle of the whole vehicle, the base of the outrigger cannot be fully retracted, off-road and passing ability Deterioration and other problems, to achieve the effect of cost saving, easy immediate replacement, and improved passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

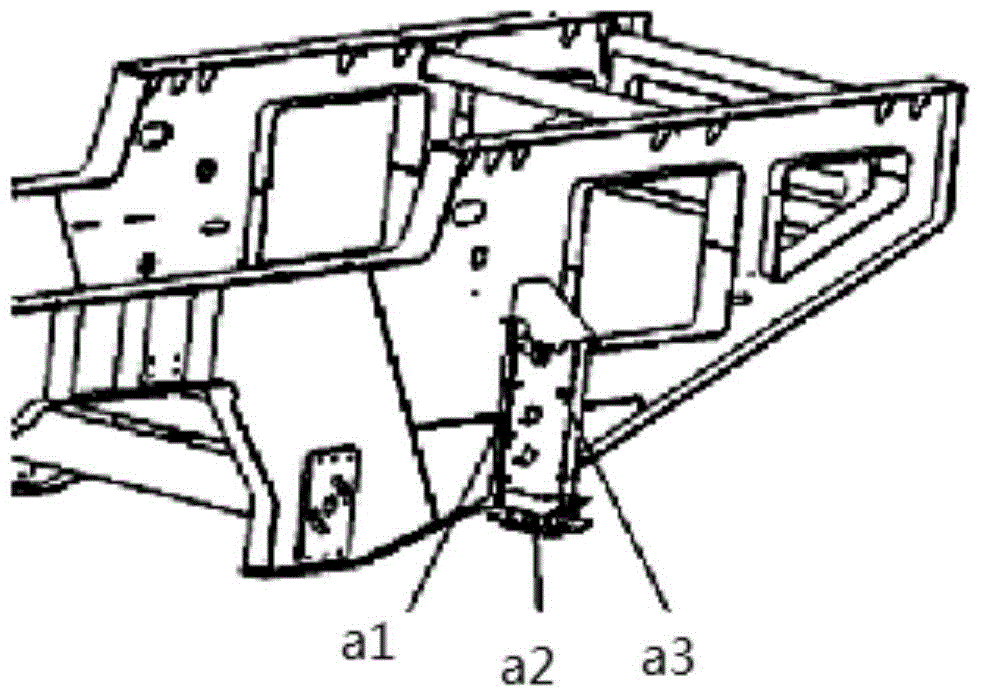

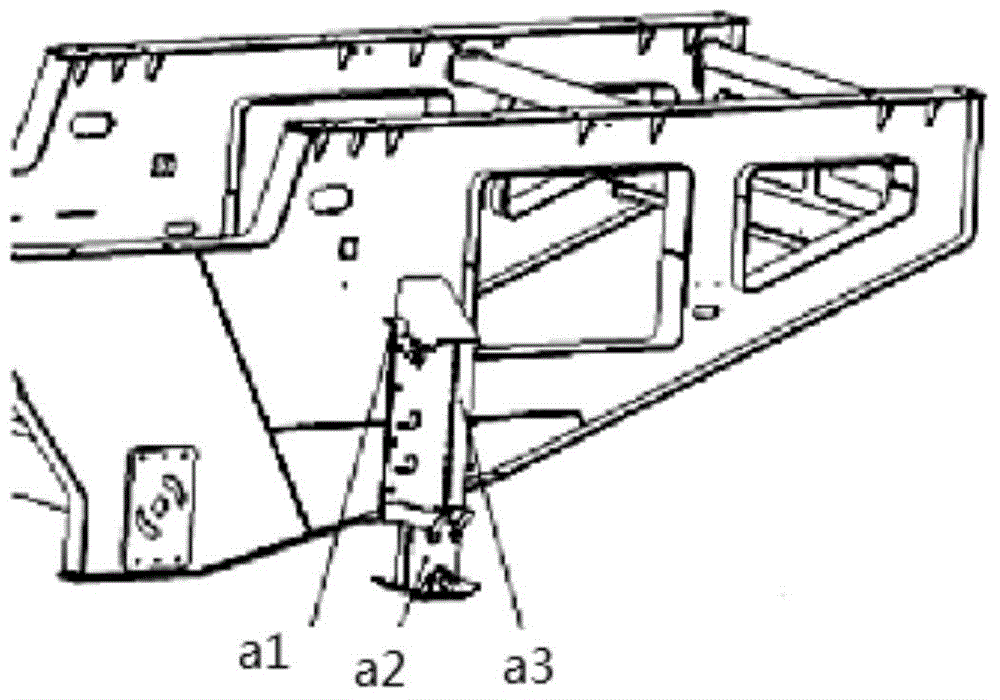

[0043] image 3 Shown is a specific embodiment of the hydraulic outrigger structure involved in the present invention. In the figure 1 is the frame body of the device to be supported. The frame body can be, for example, the frame body of a mobile crusher, or other supporting needs The frame of construction machinery. The hydraulic outrigger structure includes a outrigger base assembly 2 and a hydraulic outrigger assembly 3. The outrigger base assembly 2 can be fixedly connected to the frame body 1 of the device to be supported by means of welding or bolting.

[0044] The hydraulic outrigger structure includes a hook structure and a jacking structure, so that the hydraulic outrigger assembly 3 is hooked on the outrigger base assembly 2 through the hook structure, and in the working state, the hydraulic outrigger assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com