A New Bicycle Sprocket Structure

A new type of technology for bicycles and sprockets, applied in the crank structure, vehicle components, transportation and packaging, etc., can solve the problems of increased lateral size of the front sprocket shaft, muscle tissue fatigue, joint wear, etc., to improve installation compatibility, The effect of reducing the number of parts and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

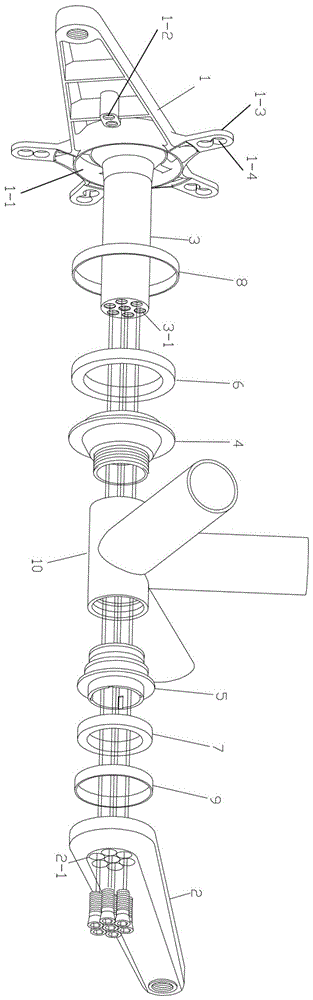

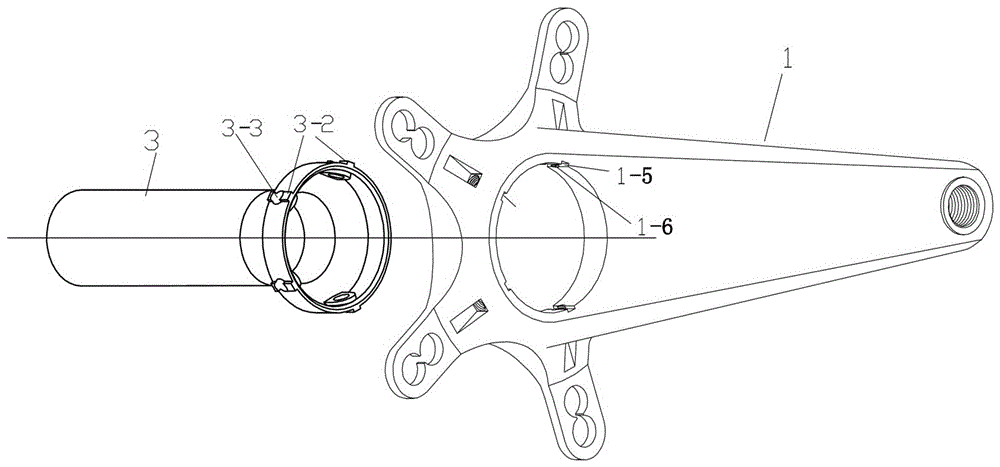

[0020] see figure 1 , the specific embodiment adopts the following technical scheme: it includes a first crank arm 1, a second crank arm 2, a shaft 3, a first cup 4, a second cup 5, a first bearing device 6, a second bearing Device 7, the first backing ring 8 and the second backing ring 9, the first crank arm 1 is provided with an annular concave base 1-1 for installing and accommodating the first bearing device 6, and the first bearing device 6 is arranged in the ring In the concave base 1-1, a first backing ring 8 is provided between the inner wall of the annular concave base 1-1 and the outer wall of the first bearing device 6, and the shaft 3 passes through the bottom bracket 10 and revolves around the bottom bracket 10 axis Rotate, one end of the shaft 3 is set in the annular concave base 1-1 on the first crank arm 1, and several internal thread holes 3-1 are set on the side of the other end of the shaft 3, and the second crank arm 2 corresponds to the shaft 3 Several fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com