Adjustable line winding mechanism of coiling machine of halogen-free crosslinked lines

A technology of wire take-up mechanism and cross-linking wire, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., which can solve problems such as low efficiency, inconsistent length of wire reel, uneven cable coiling, etc. To achieve the effect of ensuring quality, ensuring filling degree and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better illustrate the technical solution of the present invention, the present invention will be further explained below through specific embodiments.

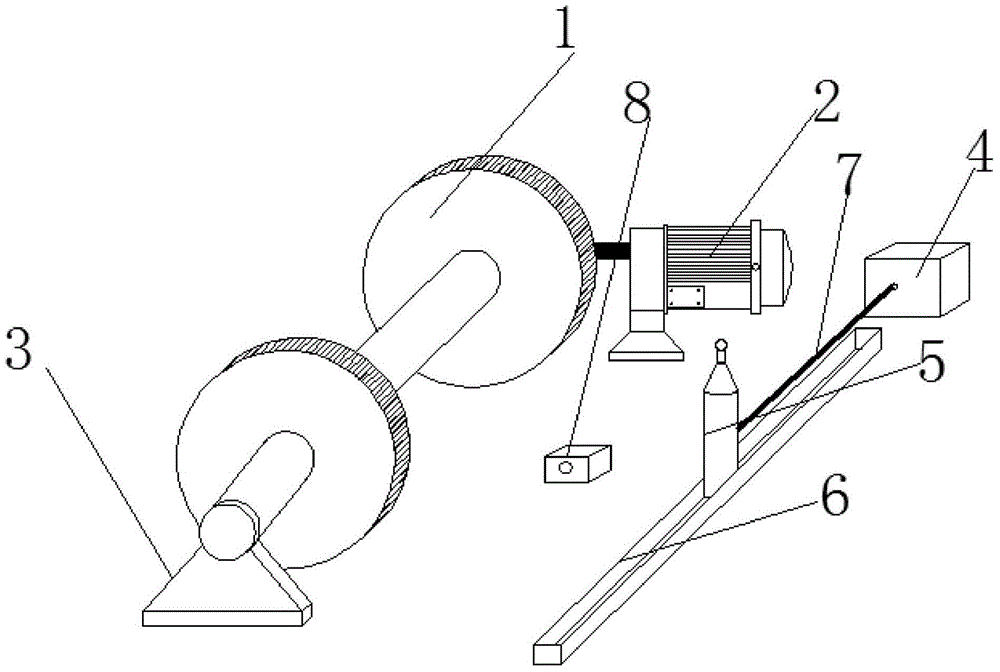

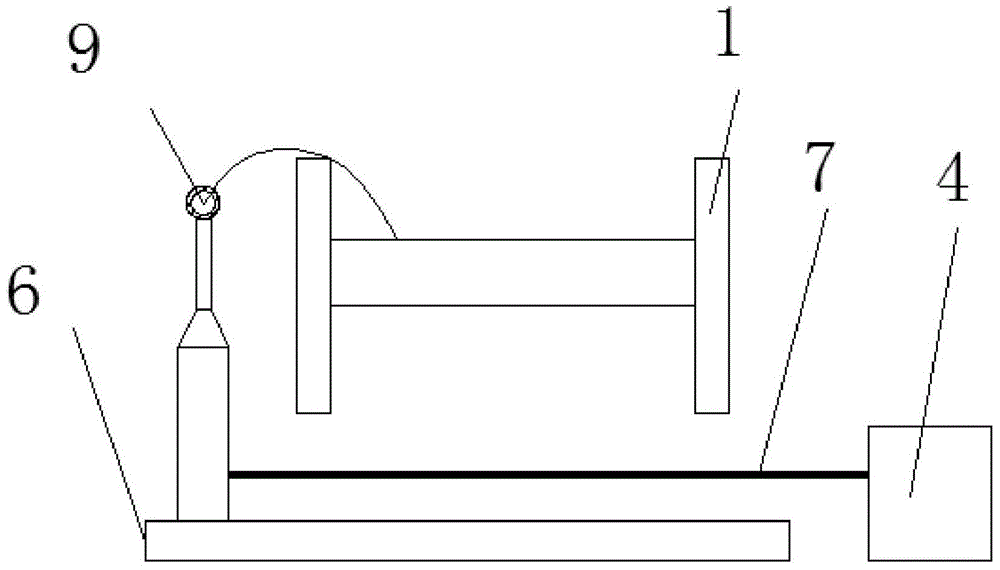

[0016] Such as figure 1 As shown, the I-shaped wheel 1 is fixed by two support frames 3 (the other side is blocked in the figure so it is not shown), and the motor 2 is connected with one side of the I-shaped wheel 1 to drive the I-shaped wheel 1 to rotate and take up the wire. The bottom of the cylinder 5 is placed in the linear slideway 6 and can move back and forth along the linear slideway 6. The traction device 4 is arranged on one end of the linear slideway 6 , and a drawbar 7 is drawn out to be welded and fixed with the cylinder 5 for driving the cylinder 5 to move back and forth in the linear slideway 6 . combine image 3 As shown, a limit ring 9 is welded to the output end of the top of the cylinder 5, and the linear slideway 6 is parallel to the position of the I-shaped wheel 1 and perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com