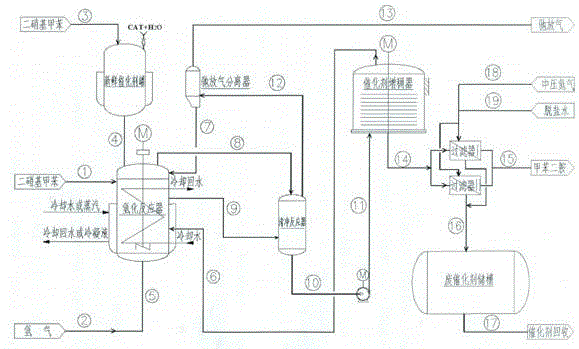

Continuous production process of dinitrotoluene for synthesis of toluenediamine by low-pressure hydrogenation, catalyst and catalyst preparation method

A technology of dinitrotoluene and toluenediamine, which is applied in the fields of chemical recovery and organic chemistry, and can solve the problems of large investment in equipment, the need for additional solvents, and high reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

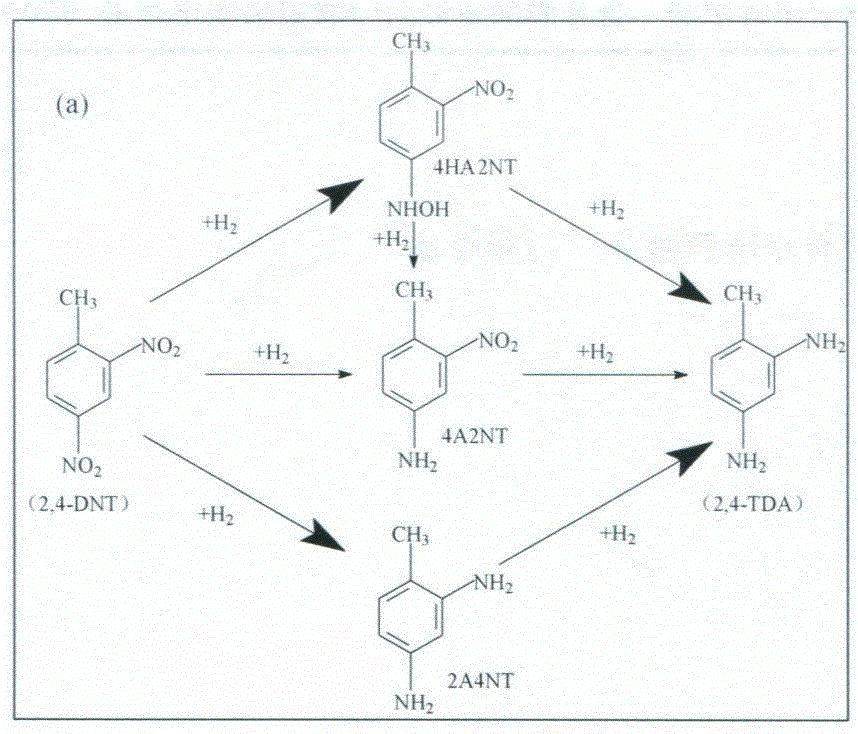

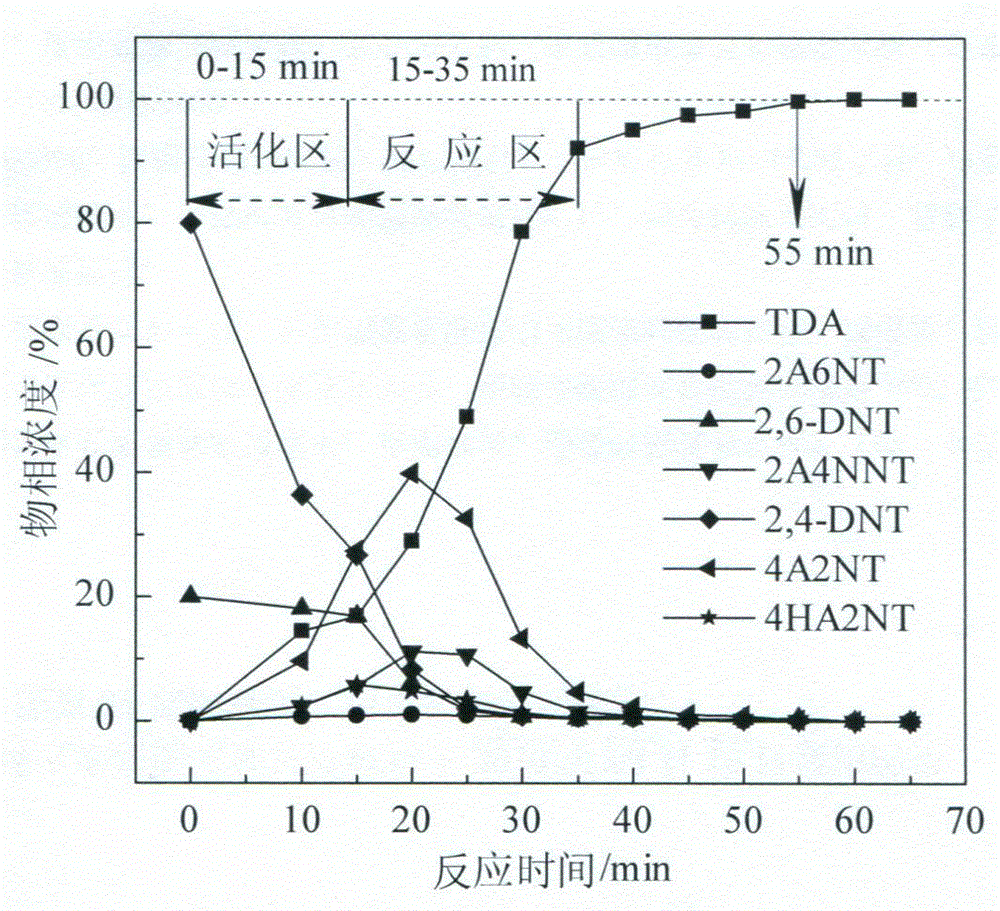

Method used

Image

Examples

Embodiment 1

[0053] Mix 6μm nickel powder, 5μm aluminum powder and 8μm auxiliary metal powder with a mass fraction of Ni55wt%—Al40wt%—Fe5wt%, and place them in a crucible with a funnel at the bottom and inlaid with SiC. It is heated to 1600℃ and melted at a rate of min., and the alloy powder is obtained after 0.8MPa Ar gasification and atomization. The cooling rate is 1.0×10 6 K / s; Mix the alloy powder and NaOH powder in a mass ratio of 1:1, and add 3 times the volume of the alloy powder to the container at room temperature. The dropping acceleration keeps the material evenly wet but does not form a liquid phase; After the dropwise addition, the suspension was sonicated for 40 min under the conditions of 20kHZ and 70°C, and then washed with distilled water to obtain the catalyst, which was stored in water for later use. The specific process route and reaction conditions of the catalyst prepared in this example for hydrogenation of dinitrotoluene are as follows:

[0054] (1) Prepare the prepar...

Embodiment 2

[0059] Mix 5μm nickel powder, 7μm aluminum powder and 7μm auxiliary metal powder with a mass fraction of Ni53wt%—Al43wt%—auxiliary 4wt%, and place them in a crucible with a funnel at the bottom and inlaid with SiC. It is heated to 1550°C at a rate of ℃ / min to melt, and the alloy powder is obtained after being vaporized and atomized by 0.9MPa Ar. The cooling rate is 1.2×10 6 K / s; Mix the alloy and NaOH powder at a mass ratio of 1.1:1, and add 4 times the volume of the alloy powder to the container at room temperature. The dropping rate keeps the material evenly wet but does not form a liquid phase; After the addition, the suspension was sonicated for 35 min under the conditions of 30kHZ and 60°C, and then washed with distilled water to obtain the target catalyst, which was stored in water for later use. The specific process route and reaction conditions of the catalyst prepared in this example for hydrogenation of dinitrotoluene are as follows:

[0060] (1) Prepare the prepared Ra...

Embodiment 3

[0065] Mix 4μm nickel powder, 9μm aluminum powder and 6μm auxiliary metal powder with a mass fraction of Ni53wt%—Al45wt%—auxiliary 2wt%, and place them in a crucible with a funnel at the bottom and inlaid with SiC. It is heated to 1500℃ to melt at the rate of ℃ / min, and the alloy powder is obtained after vaporization and atomization with 1.0MPa Ar. The cooling rate is 1.3×10 6 K / s; Mix the alloy and NaOH powder in a mass ratio of 1:2, and add 5 times the volume of the alloy powder to the container at room temperature. The dropping rate keeps the material evenly wet but does not form a liquid phase; After the addition, the suspension was sonicated at 50kHZ and 60°C for 30min, and then washed with distilled water to obtain the catalyst, which was stored in water for later use. The specific process route and reaction conditions of the catalyst prepared in this example for hydrogenation of dinitrotoluene are as follows:

[0066] (1) Prepare the prepared Raney-Ni catalyst and DNT in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com