Aluminizing technology method for blade

A process method and blade technology, applied in metal material coating process, pressure inorganic powder coating, coating, etc., can solve the problems of production waste and high production cost, achieve simple process, reduce production cost, and avoid production waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

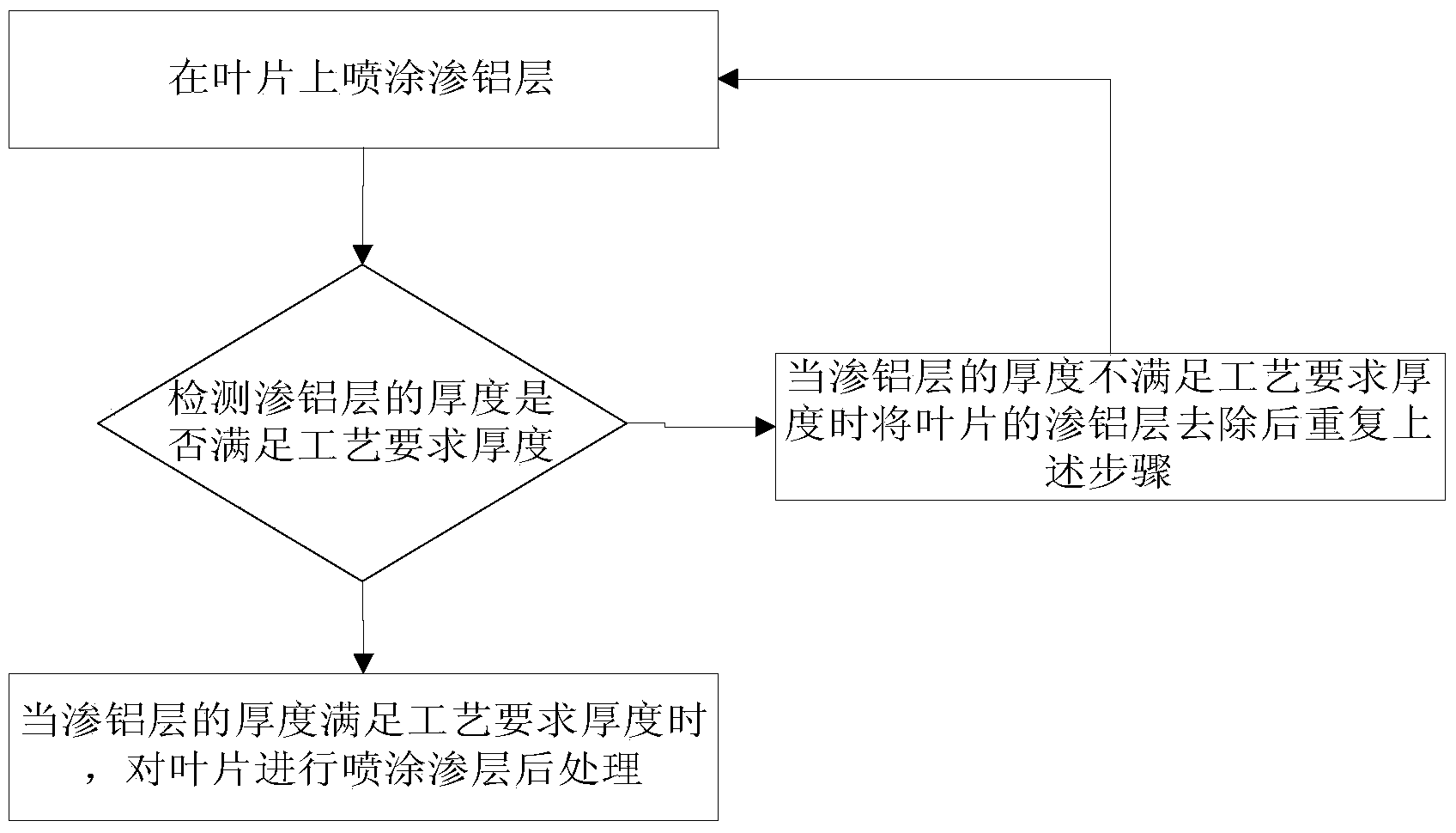

[0019] The invention provides an aluminizing process for blades. As shown in the figure, the aluminizing process method includes step S1, step S2 and step S3, step S1: spraying the aluminized layer on the blade; step S2: detecting whether the thickness of the aluminized layer meets the process requirement thickness, when the aluminized layer When the thickness meets the thickness required by the process, the blade is sprayed and treated after the infiltration layer; when the thickness of the aluminized layer does not meet the thickness required by the process, continue to step S3; step S3: remove the aluminized layer of the blade and repeat steps S1 and S2 . Because the thickness of the aluminized layer does not meet the thickness required by the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com