A kind of sewage dredging treatment method of cutter suction vessel

A treatment method, the technology of the cutter suction ship, applied to the operation method of excavator/dredger, mechanically driven excavator/dredger, pipe group with holes for cleaning, etc., can solve the problem of excessive material equipment and damage to steel pipes , time, manpower, material resources, financial resources and other issues, to achieve good sludge discharge effect and increase the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

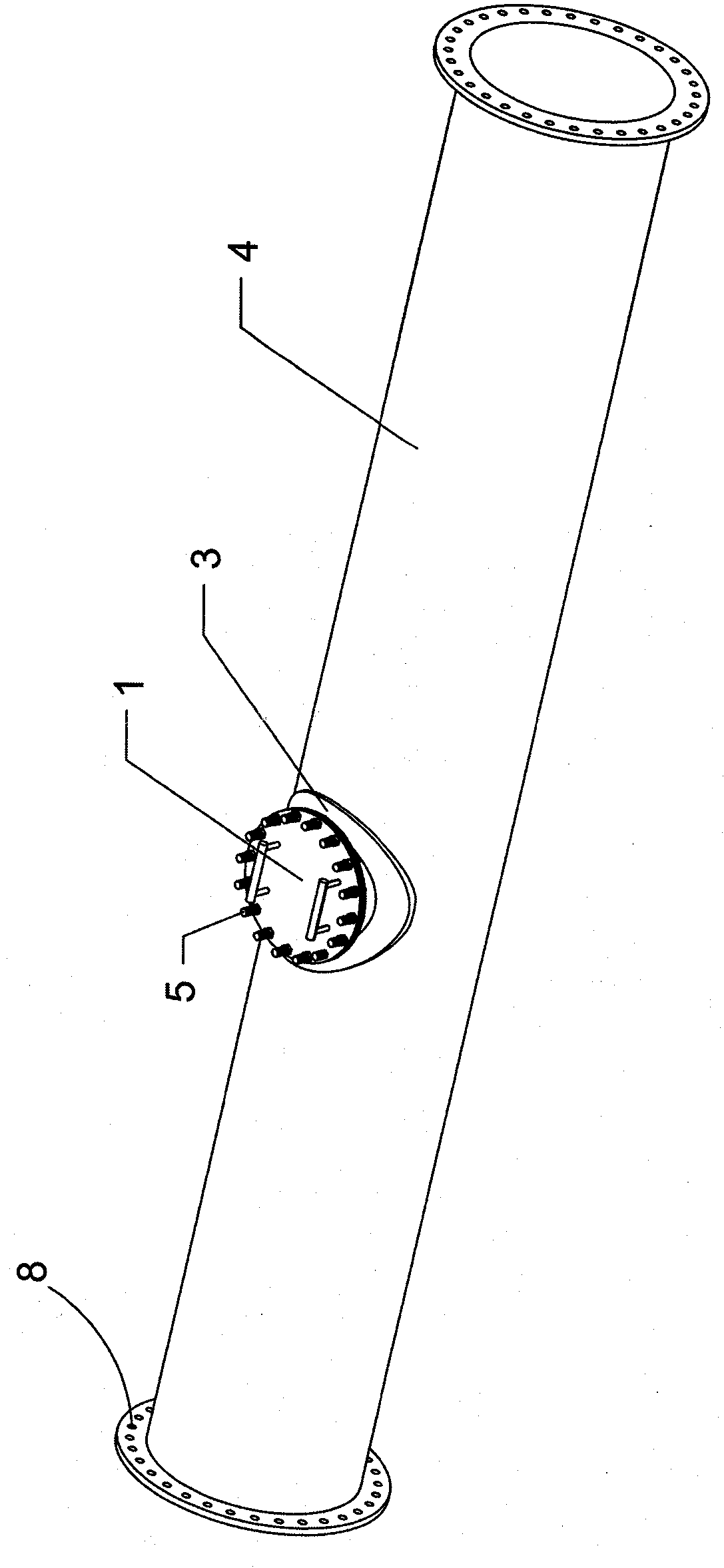

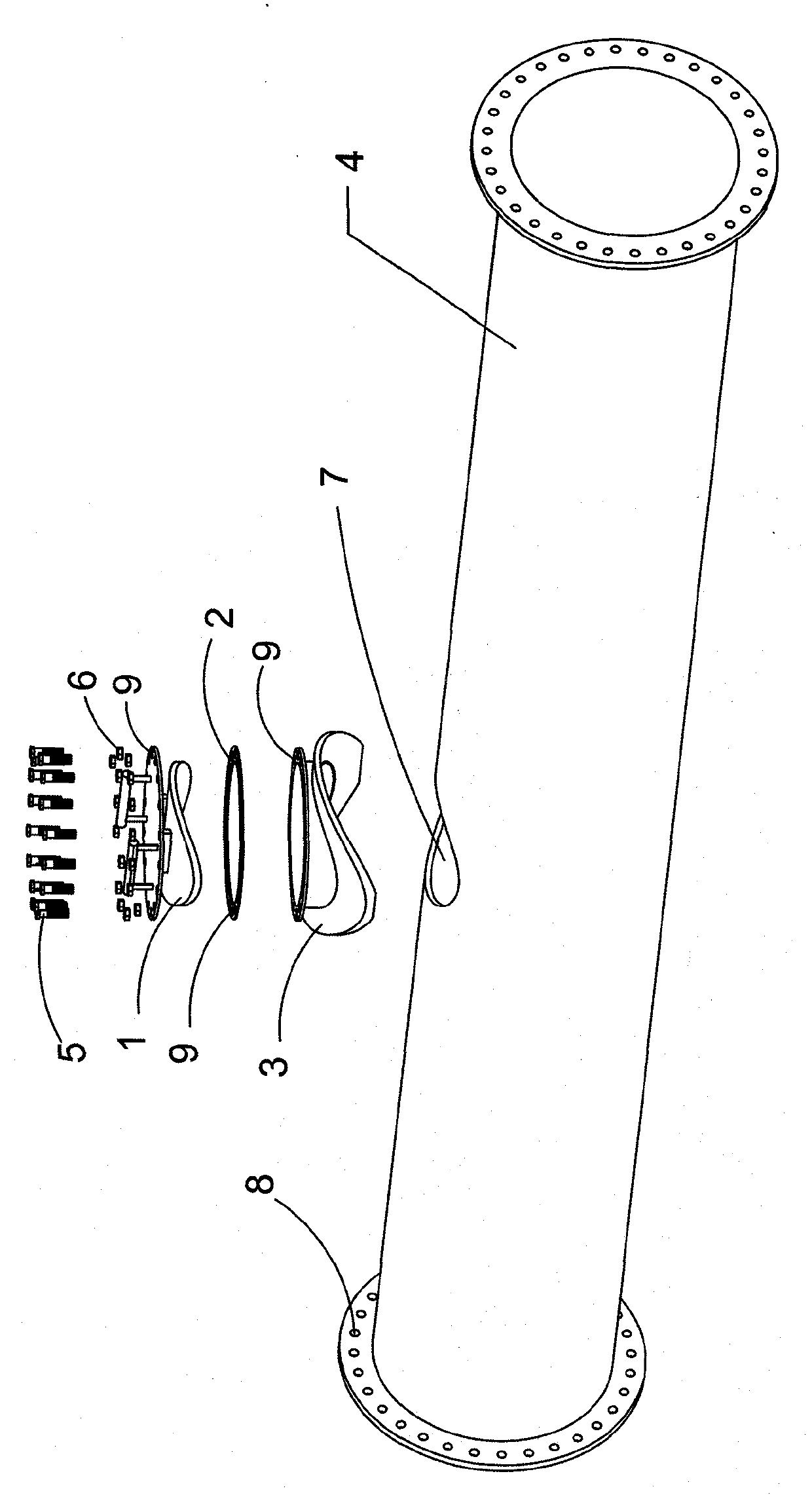

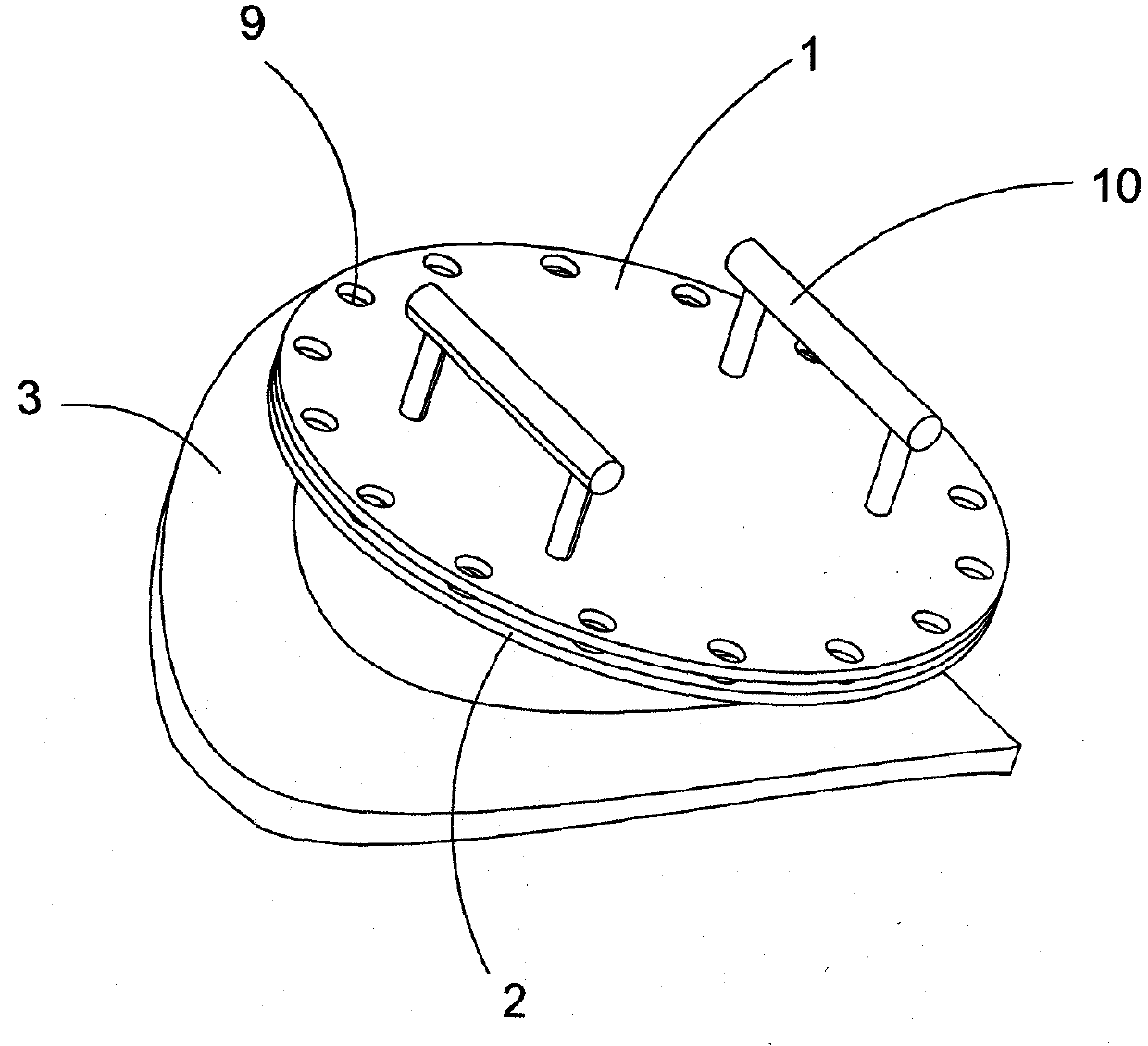

[0016] Such as figure 1 , figure 2 and image 3 As shown, the anti-clogging special mud discharge steel pipe for cutter suction ships of the present invention includes a steel pipe main body 4; the side surface of the steel pipe main body 4 is provided with a discharge hole 7 near the middle section; the position above the discharge hole 7 is welded with The middle connecting piece 3 ; the rubber pad 2 and the handle cover 1 are installed above the middle connecting piece 3 ; the handle cover 1 is arranged above the rubber pad 2 .

[0017] The middle connector 3, the rubber pad 2 and the handle cover 1 are all provided with screw holes 9; the rubber pad 2, the handle cover 1 and the middle connector 3 are connected by screws 5 and nuts 6; Both ends of the steel pipe body 4 are respectively provided with connecting holes 8; the upper end of the handle cover 1 is fixed with a U-shaped handle 10 .

[0018] The sewage dredging treatment method of a cutter suction ship of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com