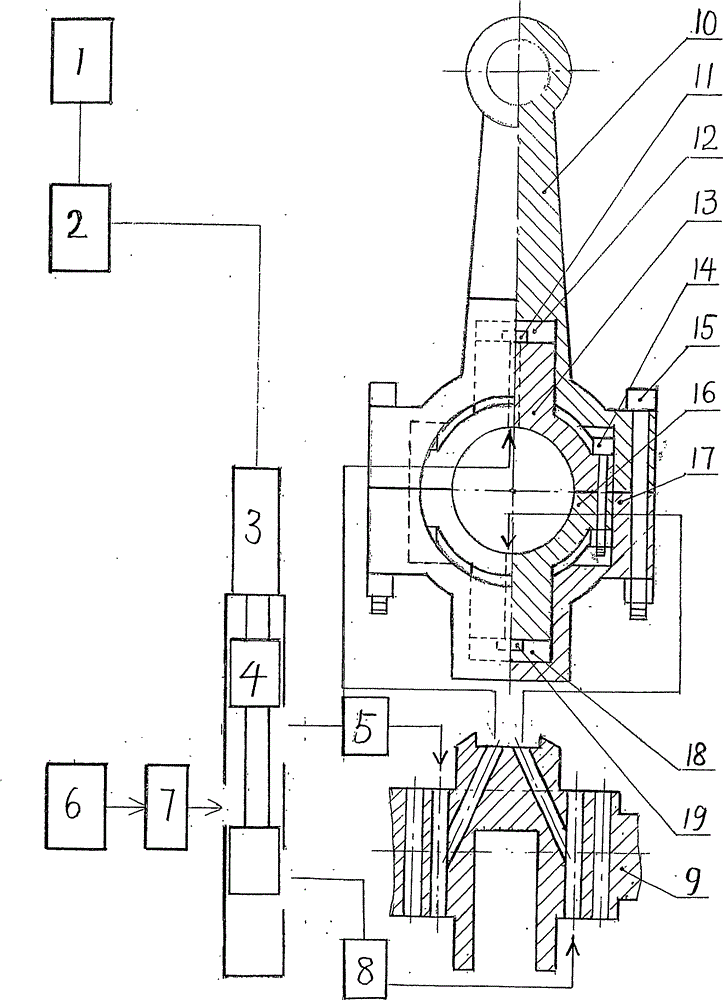

Engine connecting rod mechanism with variable compression ratio

A technology of engine connecting rod and connecting rod structure, which is applied in the direction of engine control, machine/engine, connecting rod, etc., and can solve the problems of insufficient engine performance, knocking, large thermal load and mechanical load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] After starting the engine, the engine control module (2) judges the engine speed through the signal of the engine speed sensor (1). Valve (7), cylinder body oil passage (5), crankshaft (9) oil passage, and check valve (11) enter the high-pressure chamber (12), so that the connecting rod inner upper cover (13) and the connecting rod inner lower cover (16 ) moves down along the guide groove of the outer assembly of the connecting rod body (10) and the connecting rod outer cover (17), and extends the working length of the connecting rod to increase the compression ratio of the engine, thereby increasing the low speed of the engine thermal efficiency and comprehensive performance, the one-way valve (11) is closed during the compression, work, and exhaust strokes so that the oil in the high-pressure chamber (12) cannot overflow, and the incompressibility of the oil makes the connecting rod of this invention The crankshaft is driven as a whole to rotate. During this process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com