Energy-saving Fuel Gas System

A technology of gas and supporting gas, applied in burners, combustion methods, combustion types, etc., can solve problems such as waste of resources, and achieve high-strength energy-saving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

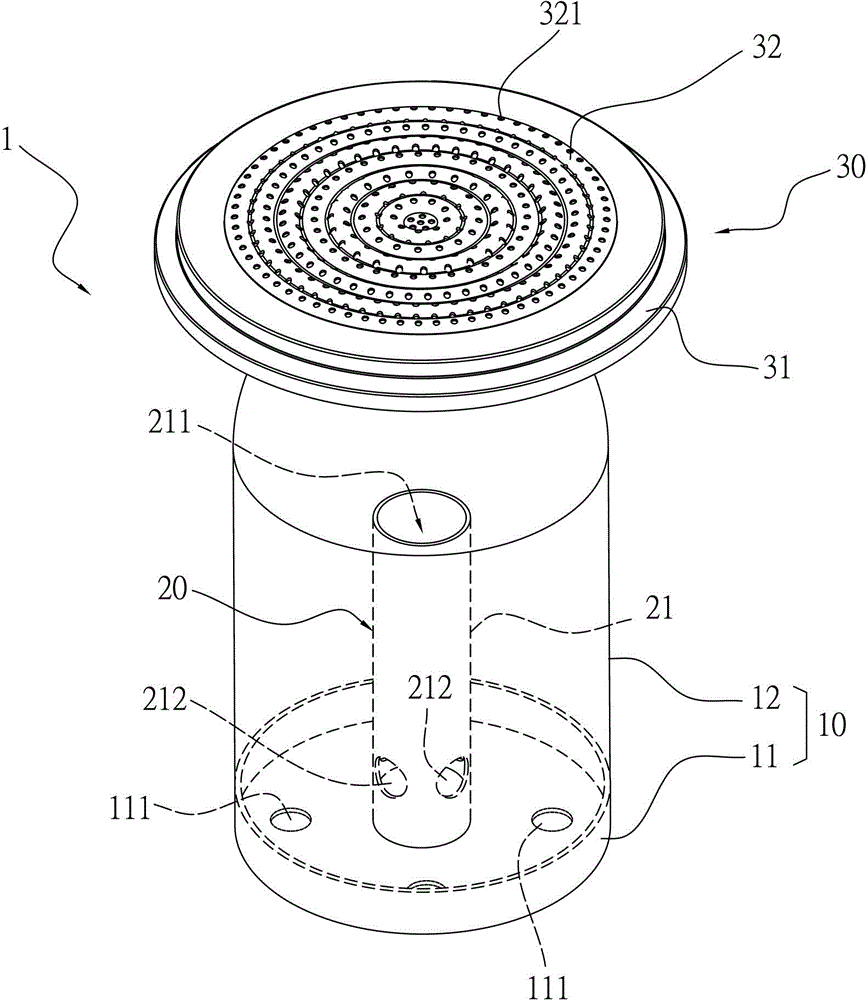

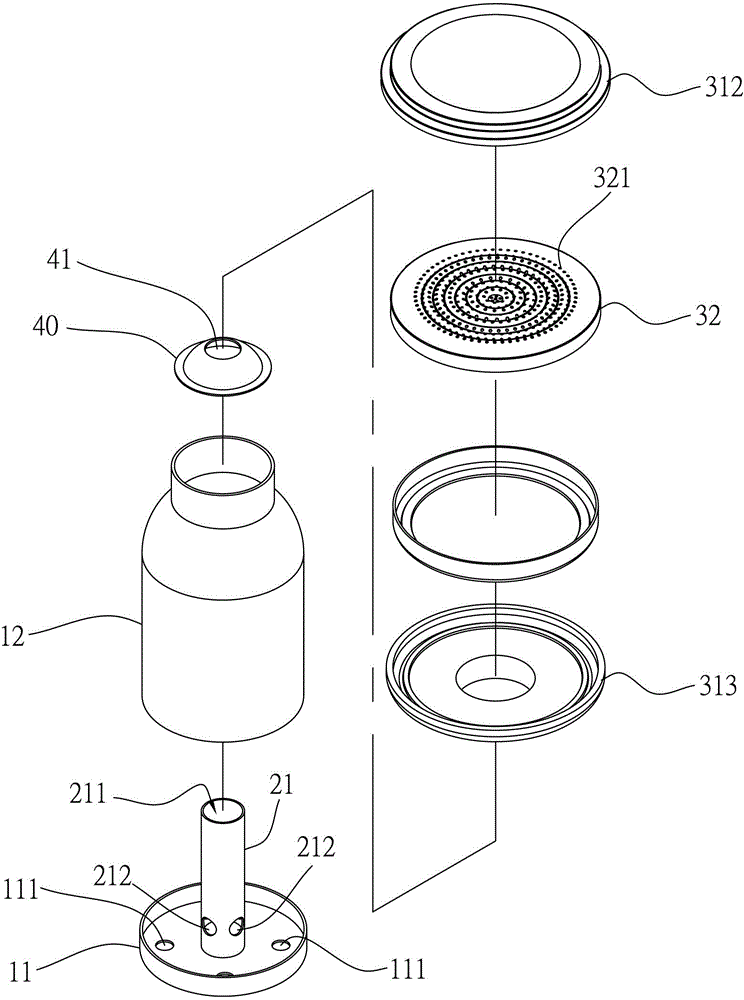

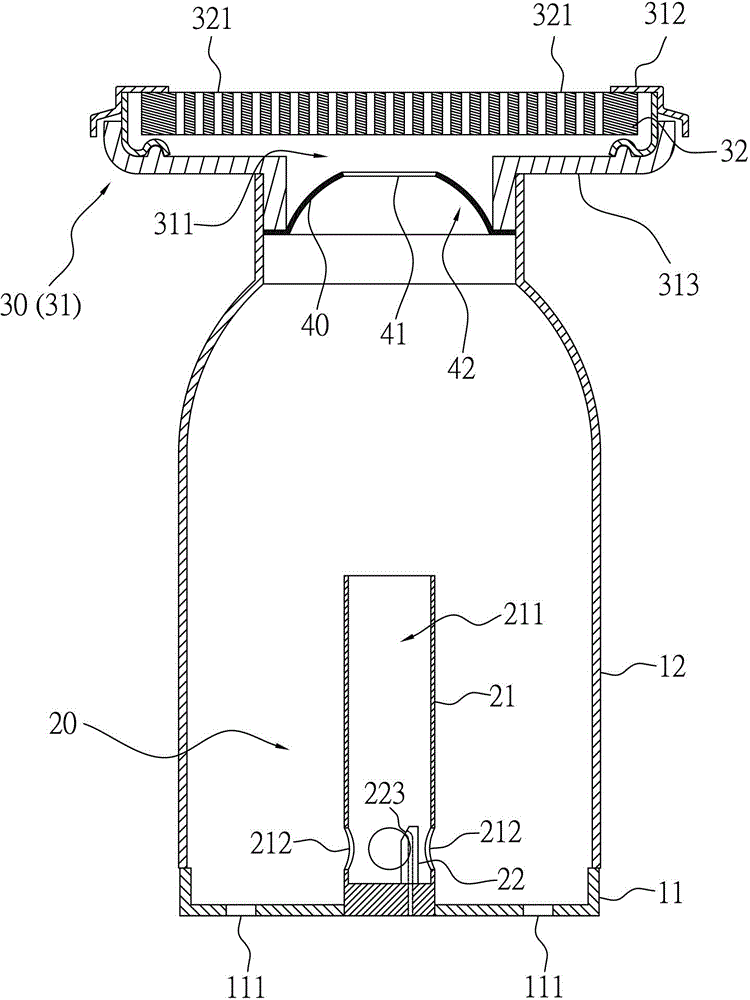

[0086] see Figure 1 to Figure 3 The schematic diagram of the first embodiment of the present invention is shown, the energy-saving gas system 1 of the present invention includes an outer shell 10 , a pre-mixing module 20 , an expansion-mixing module 30 and a fairing 40 . Wherein, the outer shell 10 includes a base 11 and a side shell 12, the base 11 is combined under the side shell 12, and the base is provided with at least one second gas-supporting inlet 111 for allowing external air (gas-supporting gas) to flow into the shell Body 10.

[0087] The premixing module 20 is arranged on the base 11, and includes a pipe body 21 and a gas injection unit 22. The gas injection unit 22 is arranged at one end of the pipe body 21, and is arranged on the base 11 together with the pipe body 21. The pipe body 21 is A premixing space 211 is provided above the gas injection unit 22, and the gas injection unit 22 is provided with a gas injection port 223 for providing gas injection into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com