Method for detecting work efficiency of PMD rubbing and twisting device for optical fibers

An optical fiber and working technology, which is applied in the field of inspecting the working effect of the optical fiber PMD twisting device, can solve the problems that the influence of the optical fiber PMD index is not obvious, maintain or improve the stability of the optical fiber PMD index, etc., and achieve the effect of simple operation and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

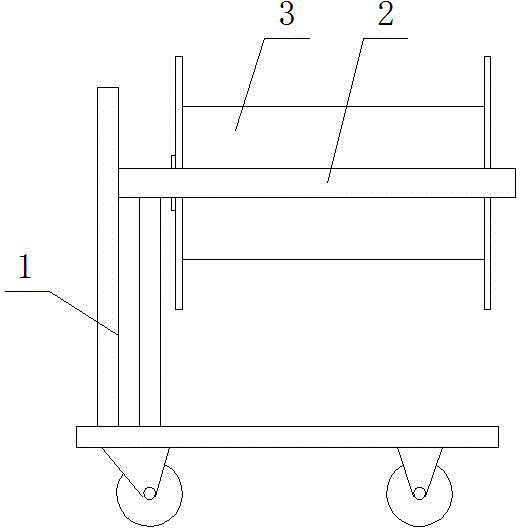

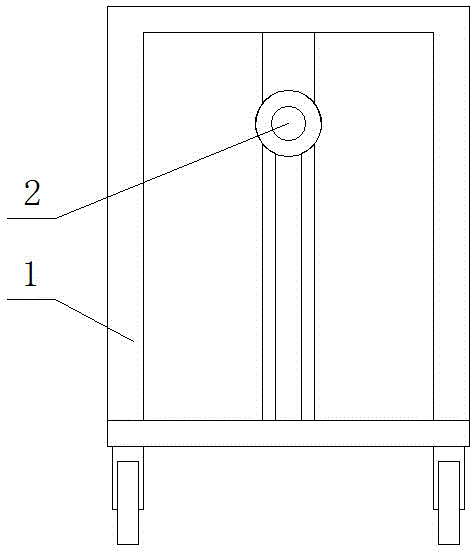

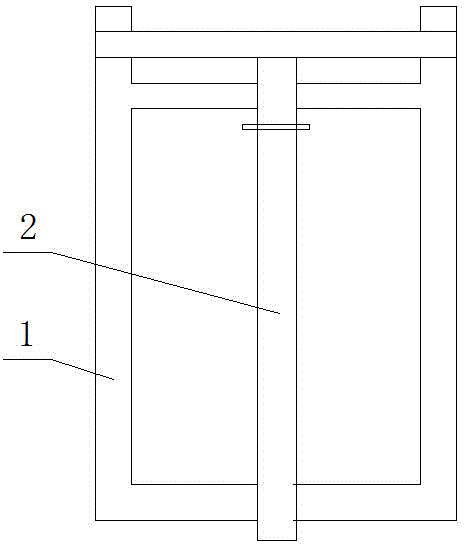

[0020] The method of testing the working effect of the optical fiber PMD twisting device requires three people to complete the work of testing the twisting of the optical fiber. The division of labor of the three people is: one of them is responsible for unwinding, one is responsible for sampling and testing the twisting times of the optical fiber, and one is responsible for recording the twisting data of the optical fiber. The specific test steps are as follows: (see attached Figure 1~3 ).

[0021] Step 1: Place the large-scale optical fiber 3 unloaded from the machine that has been twisted by the PMD twisting device on the cantilever shaft 2 of the large-scale optical fiber pay-off frame 1. The large-scale optical fiber 3 has not been screened and rewound.

[0022] Step 2: After removing 20m of the outer end of the twisted fiber wound on the large disk, the sampling person pinches the twisted fiber head tightly to ensure that the twist of the twisted fiber is not released. ...

Embodiment 2

[0027] The method of testing the working effect of the optical fiber PMD twisting device requires three people to complete the work of testing the twisting of the optical fiber. The division of labor of the three people is: one of them is responsible for unwinding, one is responsible for sampling and testing the twisting times of the optical fiber, and one is responsible for recording the twisting data of the optical fiber. The specific test steps are as follows: (see attached Figure 1~3 ).

[0028] Step 1: Place the large-scale optical fiber 3 unloaded from the machine that has been twisted by the PMD twisting device on the cantilever shaft 2 of the large-scale optical fiber pay-off frame 1. The large-scale optical fiber 3 has not been screened and rewound.

[0029] Step 2: After removing the outer end of the twisted fiber wound on the large disk for about 20m, the sampling person pinches the twisted fiber head tightly to ensure that the twist of the twisted fiber is not rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com