Optical fiber connector with long service life

A fiber optic connector, long-life technology, applied in the field of communication, can solve the problems of poor return loss index, unfavorable later operation, many disadvantages, etc., achieve good return loss index, improve service life, and increase the effect of air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

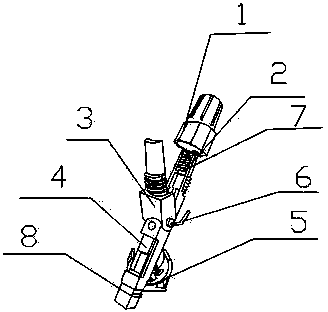

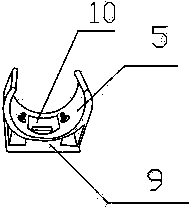

[0018] Such as Figure 1-2 As shown, the present invention includes a boot 1, a tailstock 2, a gland 3, an optical fiber cold connector 4, a moisture-proof seat 5 and a ceramic ferrule 8. One end of the tailstock 2 is socketed to the boot 1, and the other end is connected to the optical fiber at the same time. Cold joint body 4 and gland 3, gland 3 is positioned at the top of tailstock 2 and can rotate up and down around the connecting end of tailstock 2, gland 3 can rotate by being positioned at the rotary member 6 on the side of gland 3; The optical fiber cold splicer 4 is also connected to the ceramic ferrule 8 ; the moisture-proof seat 5 is located directly below the optical fiber cold splicer 4 . The moisture-proof seat 5 includes an arc-shaped support surface and a support column located below the arc-shaped support surface, and a square air hole 10 is arranged at the bottom of the arc-shaped support surface.

[0019] When using, put the tail sleeve into the outer sheat...

Embodiment 2

[0021] In this embodiment, on the basis of Embodiment 1, the preferred specific structure is as follows: the support column is a convex structure, and separate vertical plates are arranged between the two ends of the support column and the arc-shaped support surface, so that a ventilated space is formed on both sides of the support column. area. While ensuring that the support column can stably support the entire optical fiber cold splice body, it can also increase the air circulation under the cold splice body, better observe the situation under the cold splice body, and ensure the fast and accurate insertion of the fiber end face to achieve better return loss index.

[0022] Uniform fiber locking teeth 7 are arranged on the inner surface of the tailstock 2 , and fiber guide holes are arranged between the tailstock 2 and the optical fiber cold connector 4 . Ensure the accuracy and proper insertion of optical fibers.

[0023] The connecting end of the gland 3 is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com