Reactor actuation area for traveling wave reactor and manufacturing method for reactor actuation area of traveling wave reactor

A manufacturing method and technology of traveling wave reactor, which are applied in the direction of reactor, control of nuclear reaction, reduction of greenhouse gases, etc., can solve the problems such as no design plan for the starting area of traveling wave reactor, reactivity fluctuation, etc., so as to avoid reactivity fluctuation, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

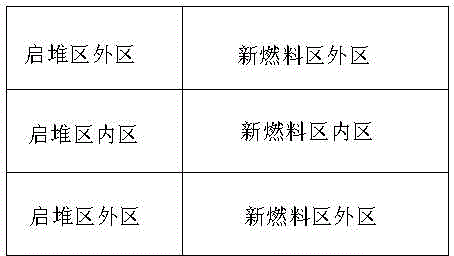

[0057] TWR start-up area, including fertile nuclides, fissile nuclides and simulated nuclides;

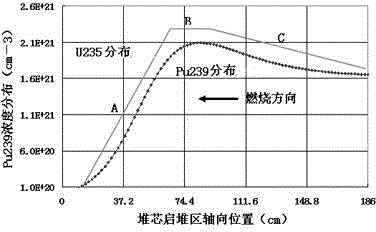

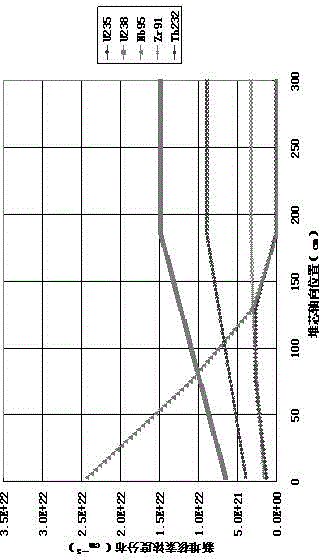

[0058] Along the direction from the front end of the start-up area to the new fuel area, the concentration of convertible nuclides gradually increases, and the concentration of convertible nuclides at the rear end of the start-up area is the same as that in the new fuel area;

[0059] Along the direction from the front end of the start-up area to the burning area, the shape of the concentration distribution curve of fissile nuclides in the start-up area and the fissile nuclides produced at that point when the propagation wave and incineration wave in the burning area pass through a certain point in sequence. The shape of the concentration change curve of the element corresponds to;

[0060] Along the direction from the front end of the start-up area to the new fuel area, the concentration of the simulated nuclide gradually decreases, and the concentration of the simulated nuclide a...

Embodiment 2

[0089] This embodiment provides a manufacturing method of the TWR start-up region as shown in Embodiment 1.

[0090] The method includes the following steps:

[0091] Initial parameter preset steps:

[0092] Along the direction from the front end of the start-up area to the new fuel area, the concentration distribution curve of fissile nuclides is divided into a gradually rising straight line segment C, a horizontal straight line segment B and a gradually falling straight line segment A

[0093] Determine the total length of the start-up area, determine the proportion of section A in the total axial length of the start-up area, determine the concentration of fissile nuclides in section B, determine the length of section B, and determine the fissile nuclei at the beginning of section C concentration of toxin;

[0094] According to the formula Calculate the concentration of other nuclides at each point in the start-up area, and obtain the concentration marking line of each n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com