Cooling system for cold insulation superconducting cable

A technology for superconducting cables and cooling systems, which is applied to superconducting devices, usage of superconducting elements, superconducting/high-conducting conductors, etc. The effect of small area, low production cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

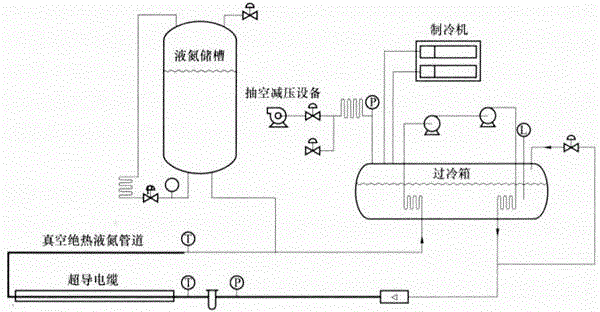

[0015] Such as figure 1 As shown, a cooling system for cold insulated superconducting cables includes a liquid nitrogen storage tank, a refrigerator, a supercooling box, evacuation and decompression equipment, and a vacuum insulated liquid nitrogen pipeline, and liquid nitrogen is arranged in the supercooling box. The refrigerator controls the temperature of the liquid nitrogen in the subcooling box, which is connected with a liquid nitrogen pump that provides liquid nitrogen circulation power, and the liquid inlet and outlet of the subcooling box respectively pass through the vacuum insulated liquid nitrogen pipeline It is connected with the superconducting cable, the liquid nitrogen storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com