Integral residual current circuit breaker

A leakage circuit breaker, integrated technology, applied in the direction of circuit breaker components, circuits, electrical components, etc., can solve the problems of inconvenient assembly, inability to disassemble and adjust, and unreasonable structural layout of leakage circuit breakers, so as to achieve firm fixation of pins Reliable, compact and inexpensive design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

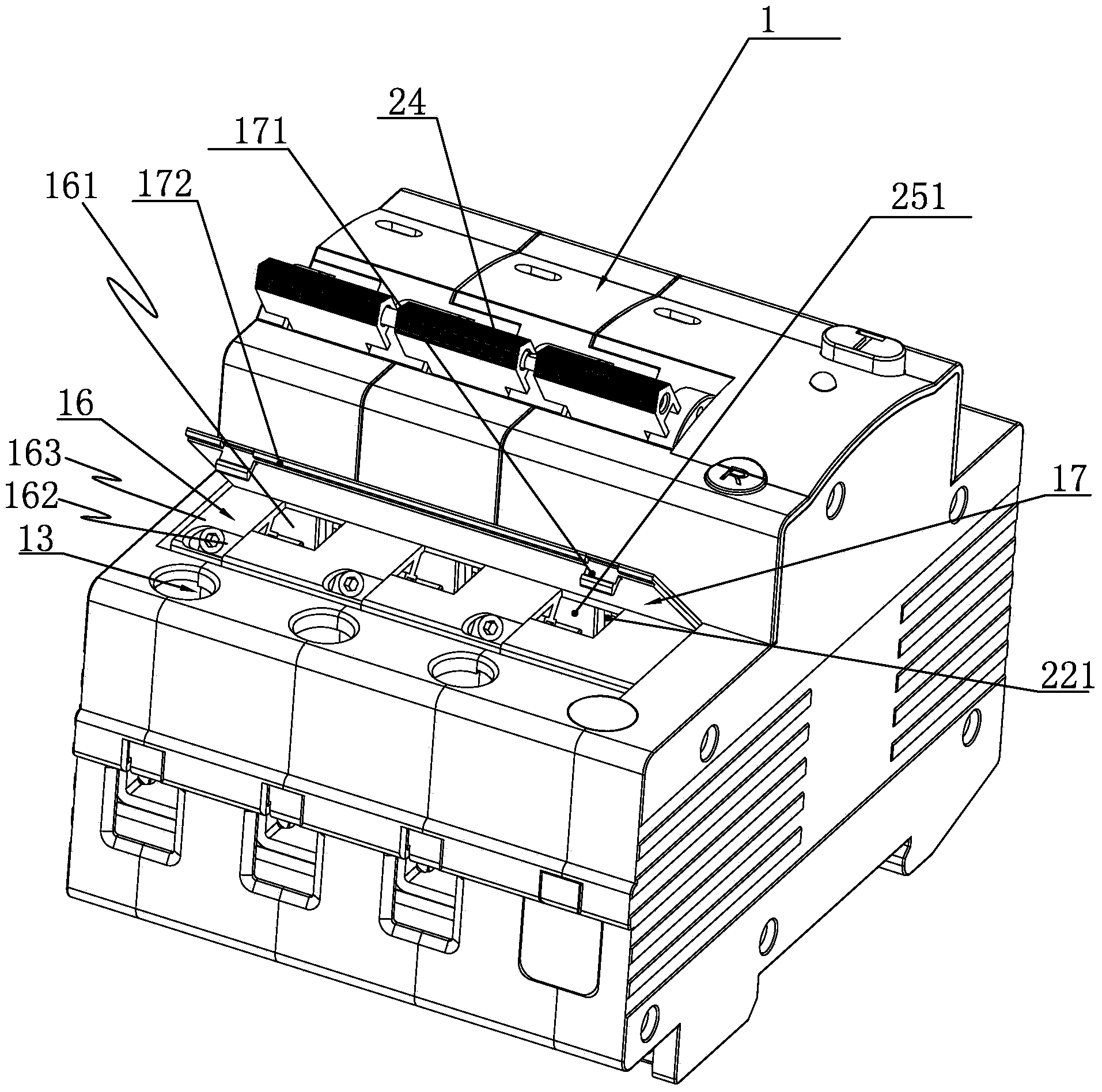

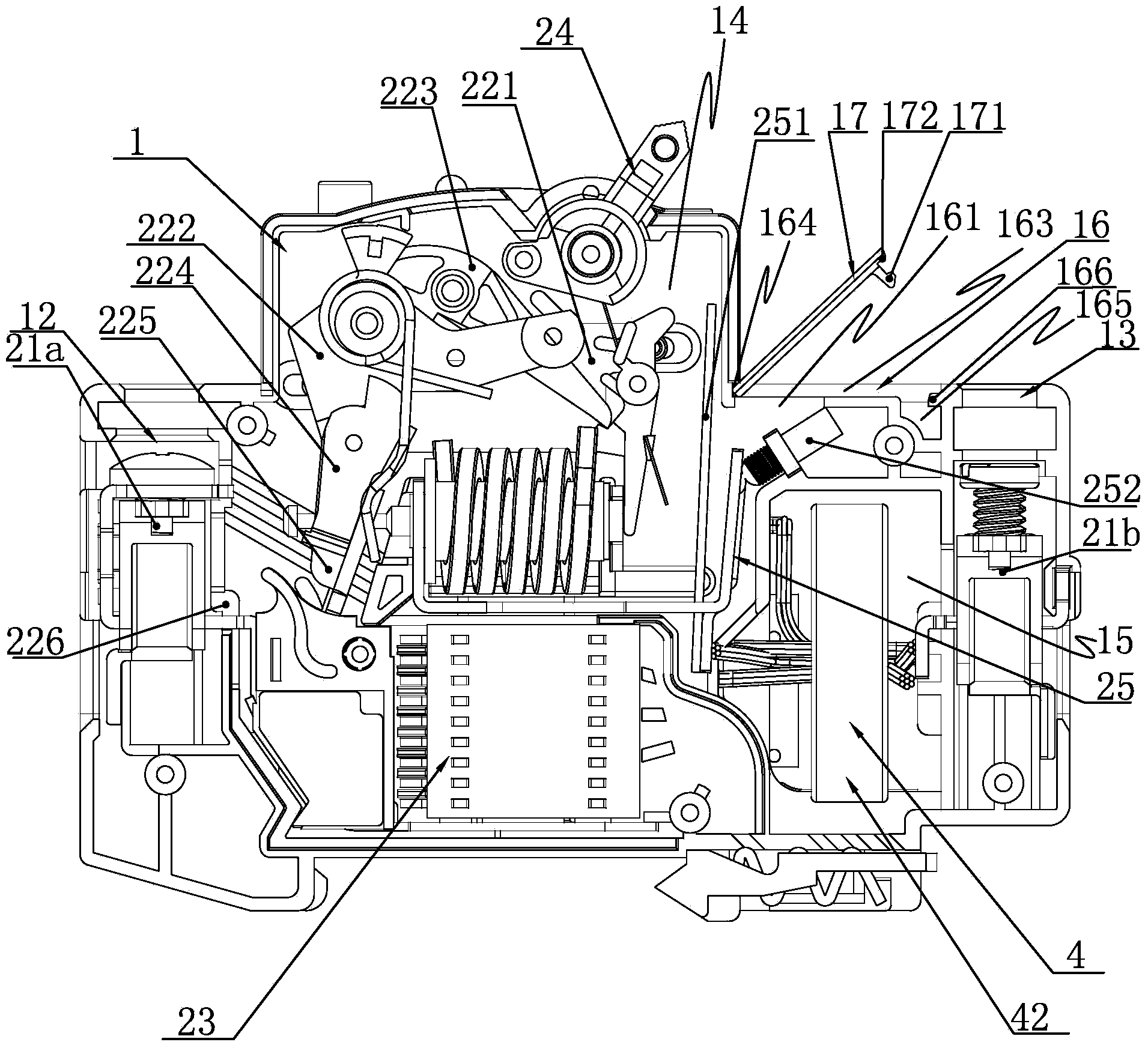

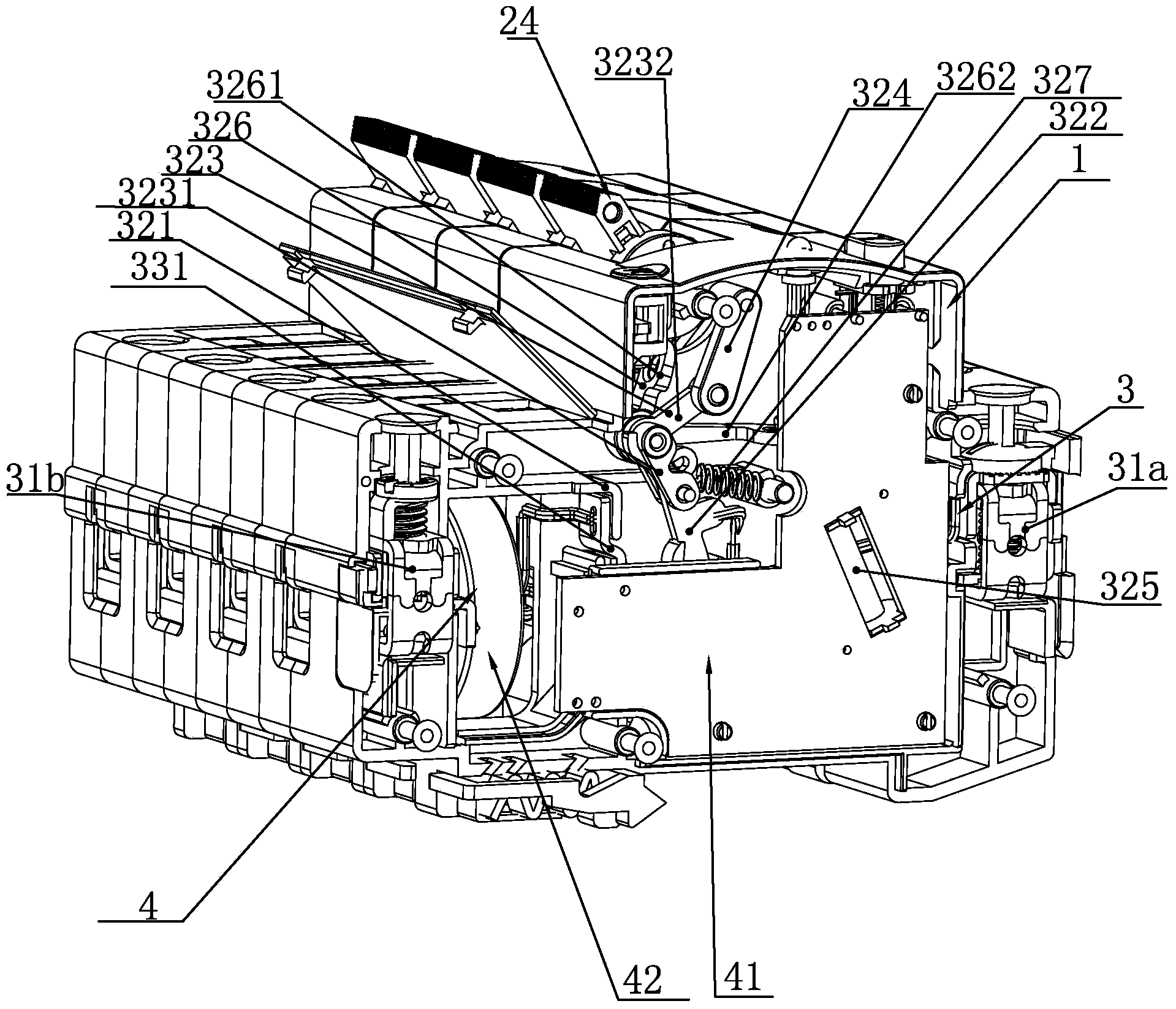

[0036] See attached figure 1 to attach Figure 10 , an integral earth leakage circuit breaker disclosed by the present invention includes a casing 1, and an N pole part 3 assembled in the casing 1, a leakage detection part 4 and at least one L pole part 2; wherein the leakage detection part 4 includes Circuit board 41 and current transformer 42, it is well-known technology well known to those skilled in the art; Described N pole part 3 includes N pole inlet and outlet wiring terminals 31a, 31b, and the wires connected on N pole outlet terminal 31b Through the transformer 42 of the leakage detection part 4; the L pole part 2 includes L pole incoming and outgoing line terminals 21a, 21b, and an L pole electromagnetic tripping device connected between the L pole incoming and outgoing line terminals 21a, 21b 22. The L-pole arc extinguishing device 23, the double gold system 25, the L-pole electromagnetic tripping device 22 is connected with the operating handle 24; the L-pole ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com