Transformer substation double bus balance enclosure insulating ladder

A technology of double busbars and insulating ladders, which is applied to electrical components, switchgear, etc., can solve the problems of insulating ladders falling out, and achieve the effects of improving safety, facilitating live work, and ensuring the safety of people and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

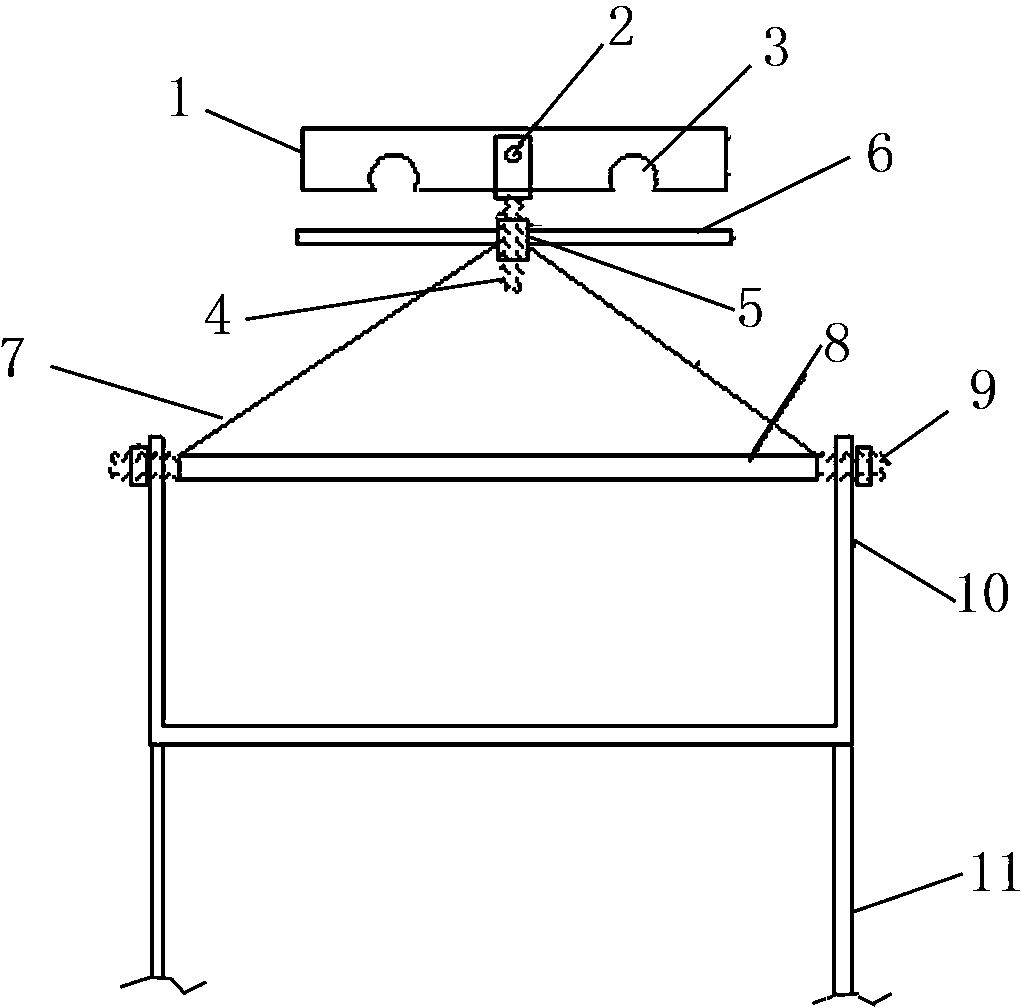

[0019] Such as figure 1 As shown, the insulating ladder body 11 is included, the upper end of the body is provided with a right-angled U-shaped insulating plate 10, the top of the insulating plate is provided with a crossbeam 8, and the two ends of the crossbeam are fixed with the insulating plate by through-hole bolts 9; One end of the two support rods is connected, and the other ends of the two support rods are fastened with the beam to form a tripod; the upper part of the tripod is provided with an aluminum alloy plate 1, and the lower part of the aluminum alloy plate is provided with a bolt 4, and the top of the bolt is inlaid inside the aluminum alloy plate. The alloy plate and the bolt are fastened by the fixing screw 2; the lower surface of the aluminum alloy plate is located on both sides of the bolt with arc-shaped grooves 3, the inner diameter of the arc-shaped groove matches the outer diameter of the busbar, and the inner diameter of the arc-shaped groove matches the...

Embodiment 2

[0021] The bolts pass through the top of the aluminum alloy plate, and other structures are the same as in Embodiment 1.

[0022] Before using the invention, the groove and the horizontal bar are in an open state. When in use, the ground staff presses the lower part of the insulating ladder body, and the operator lifts the upper part of the insulating ladder body, erects the insulating ladder, then lifts the insulating ladder and inserts it at the middle of the double busbar, rotates 90°, and the arc-shaped concave The groove is aligned with the busbar and hung on the double busbar. At this time, the ground electrician rotates the insulating ladder to move the nut on the horizontal bar up until the horizontal bar seals the arc-shaped groove, locks the busbar to stop rotating, and adjusts the angle of the insulating ladder so that The live working personnel are comfortable when going up and down the insulation ladder, and the distance between the person and the ground, the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com