Current transformer operation lead suspension device

A technology of current transformers and suspension devices, applied in switchgear, electrical components and other directions, can solve the problems of personal electric shock accidents, high-altitude falls, and high costs, and achieve the effects of reducing maintenance costs, improving work efficiency, and improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

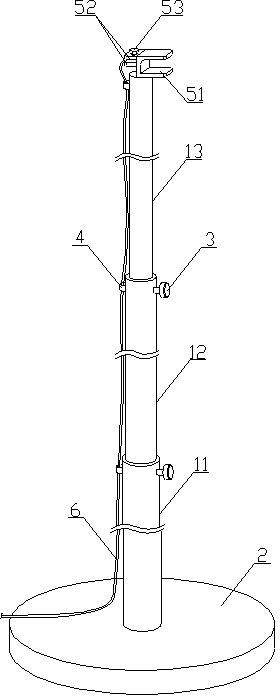

[0008] Such as figure 1 Shown: a current transformer working lead wire suspension device, including a base 2 and a movable support, the base 2 is in the shape of a steel disc, and the movable support includes a first vertical rod 11, a second vertical rod 12 and a third vertical rod 13. The first vertical rod 11, the second vertical rod 12 and the third vertical rod 13 are all made of aluminum alloy and have a hollow structure. The first vertical rod 11, the second vertical rod 12 and the third vertical rod 13 The lengths are 2.5m, 2.3m, 2m, the outer diameters of the first pole 11, the second pole 12 and the third pole 13 are 70mm, 60mm, 50mm, and the thickness is 5mm; The bottom end of the vertical rod 11 is threadedly connected with the preset fixing hole of the base 2, the bottom end of the second vertical rod 12 is placed in the first vertical rod 11, and the bottom end of the third vertical rod 13 is placed in the second vertical rod 12, so that the movable The bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com