Vacuum evaporation apparatus

An evaporation and vacuum technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problem that the evaporation rate of evaporation materials cannot be monitored independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

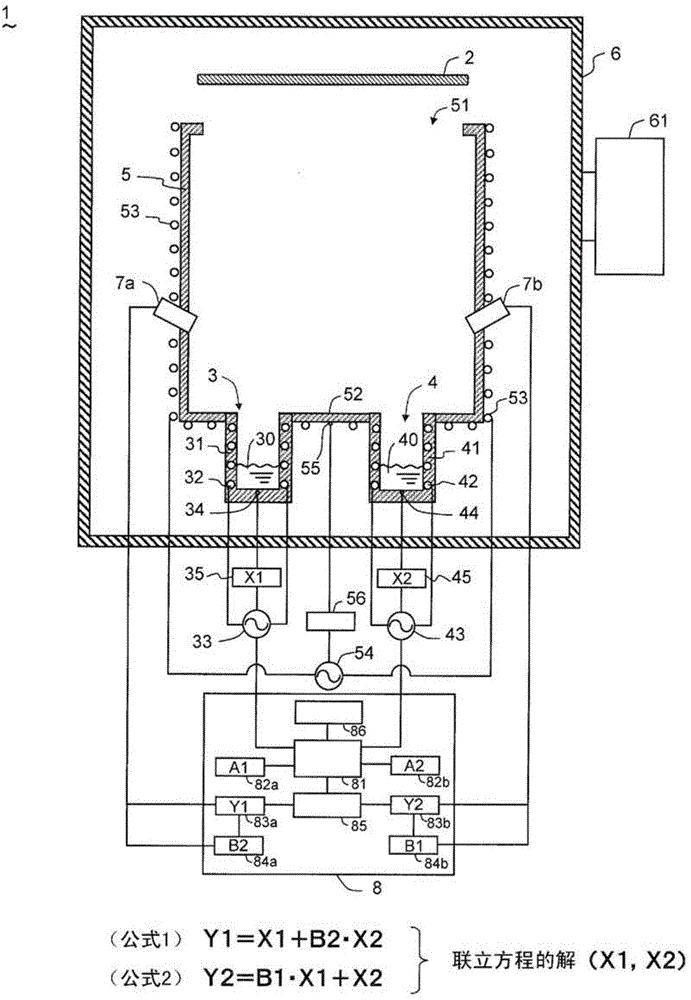

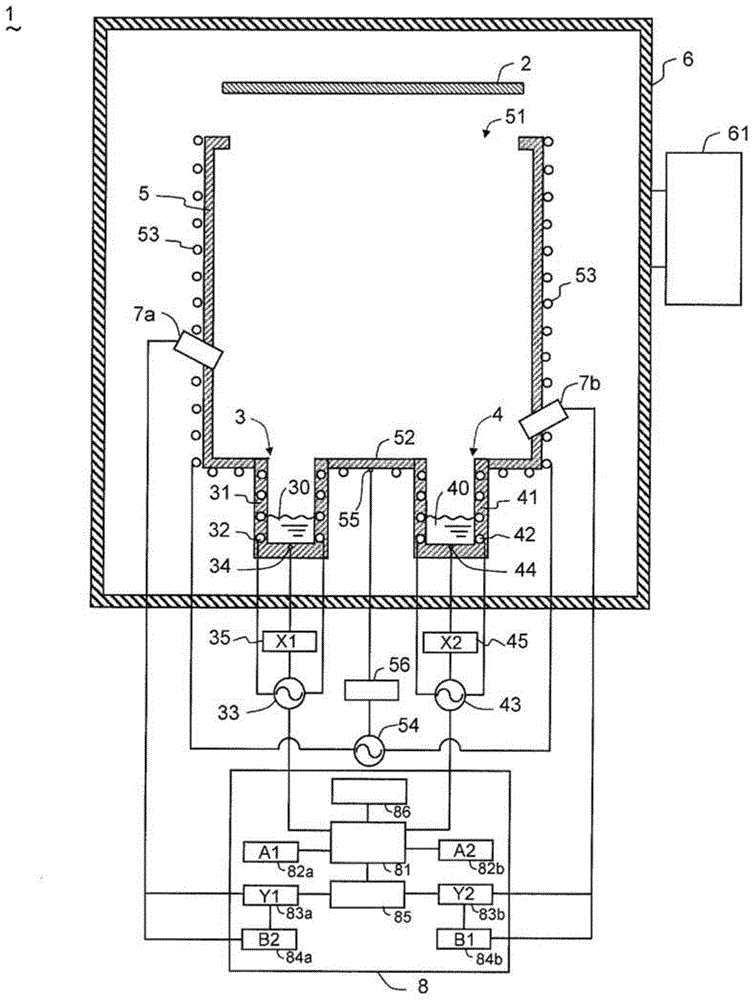

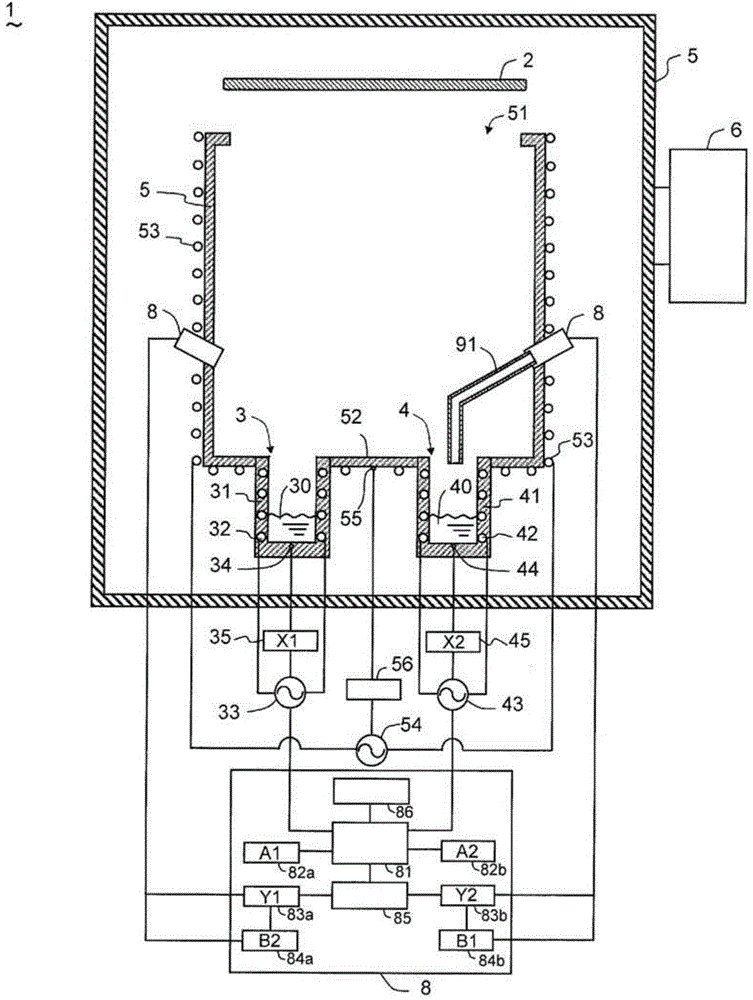

[0031] For the vacuum evaporation device according to the first embodiment of the present invention, refer to figure 1 Be explained. The vacuum evaporation device 1 of the present embodiment is used to evaporate a plurality of (in this example, two types) evaporation materials on the object to be evaporated 2, and is provided with: a first evaporation source 3 for evaporating one evaporation material 30 ; The second evaporation source 4 makes another evaporation material 40 evaporate. In addition, the vacuum evaporation device 1 also includes: a cylindrical body 5, which surrounds the space between the first and second evaporation sources 3, 4 and the vapor-deposited body 2, and has an opening surface on the vapor-deposited body 2 side; In the chamber 6, the space in which the vapor deposition object 2, the first and second evaporation sources 3 and 4, and the cylindrical body 5 are disposed is in a vacuum state. The vacuum chamber 6 is configured such that its interior can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com